Effective date: October 15, 2024

(First revision version 2.1)

This directive provides interpretation and administrative guidance for the delivery of the United States – Canada Greenhouse-Grown Plant Certification Program (GCP), a bilateral export certification program for greenhouse-grown plants shipped between Canada and the continental United States.

The Technical requirements (see definition below) and this directive must be used together.

The following change was made in version 2.1:

- Removed reference to the USDA APHIS Plants for Planting Manual

- Added an "H" before "319.37 Plants for Planting" to reflect 2019 formatting changes to subpart references and updated the web address

- Updated the web address for 7 CFR Part 360 Noxious Weed Regulations

The following change was made in version 2:

- Removed Annex 1 which addressed the transition of facilities approved under the Canadian Greenhouse Certification Program (CGCP) to the GCP. The transition period ended and D-96-12: Greenhouse Certification Program for Export of Greenhouse-Grown Plants to the United States has been repealed.

The following changes were made as part of the first revision (October 1, 2020):

- Removal of Section 5.1.7: Pest modules for regionally distributed pests. The section was not consistent with the technical requirements. The section was an example of an administrative measure to prevent the spread of regulated pests. The use of other, effective administrative and conventional measures to prevent the movement of regulated pests is permitted by the technical requirements

- Addition of instruction in Annex 1 for facilities that continue to ship under a CGCP export certification label following completion of the authorization process

- Addition of a link to the list of GCP Authorized Facilities in Canada in Appendix 2

- Addition of details to Appendix 3: Administrative requirements for export certification labels and interfacility stamps

- Addition of details to Appendix 4: Specifications and examples of export certification labels and interfacility stamps

- Addition of updated instructions and links to GCP administrative forms in Appendix 5: Forms

- Corrections to Appendix 6: GCP audit inspections under the CFIA Standard Inspection Procedure (SIP) to maintain consistency with operational guidance to CFIA inspectors: OG-2015-0937: Delivery of the Greenhouse Certification Program

This document supersedes all previous versions of directive D-16-02.

On this page

- 1.0 Legislative authority

- 2.0 Definitions, abbreviations and acronyms

- 3.0 Introduction

- 4.0 Scope

- 5.0 General requirements

- 6.0 Specific requirements

- 7.0 Administrative requirements

- 8.0 Non-compliance

- 9.0 References

- 10.0 Appendices

- Appendix 1: GCP authorization process

- Appendix 2: GCP authorized facilities in Canada

- Appendix 3: Administrative requirements for export certification labels and interfacility stamps

- Appendix 4: Specifications and examples of export certification labels and interfacility stamps

- Appendix 5: Forms

- Appendix 6: GCP audit inspections under the CFIA Standard Inspection Procedure (SIP)

1.0 Legislative authority

Plant Protection Act (S.C. 1990, c. 22)

Plant Protection Regulations (SOR/95-212)

Canadian Food Inspection Agency Act (S.C. 1997, c.6)

Canadian Food Inspection Agency Fees Notice, Canada Gazette, Part I (as amended from time to time)

2.0 Definitions, abbreviations and acronyms

Definitions of terms used in this document are found in the:

- Technical requirements, United States – Canada Greenhouse-Grown Plant Certification Program (GCP)

- International Standard for Phytosanitary Measures 5: Glossary of phytosanitary terms

- Regional Standard for Phytosanitary Measures 5: NAPPO Glossary of Phytosanitary Terms

- Plant Health Glossary of Terms.

"GCP" means the United States - Canada Greenhouse-Grown Plant Certification Program.

"Technical requirements" refers to the document titled, Technical requirements: United States – Canada Greenhouse-Grown Plant Certification Program (GCP).

For the purpose of this directive, in the event of differences in the definition of individual terms, the definition in the technical requirements glossary will prevail.

The nomenclature convention for references to the technical requirements provided in this document is "GCP Part x, Section y".

3.0 Introduction

The GCP is a bilateral arrangement between the Canadian Food Inspection Agency (CFIA) and the United States Department of Agriculture: Animal and Plant Health Inspection Service (APHIS) that details the requirements for facilities to be authorized to ship greenhouse-grown plants between the continental United States and Canada under an export certification label in lieu of a phytosanitary certificate.

Both Canada and the United States require phytosanitary certification that consignments of plants moving between the 2 countries are free from regulated pests. Plants produced and shipped under the GCP are free from regulated pests and meet the phytosanitary import requirements of both Canada and the United States.

The GCP is a systems approach that is audited by the CFIA. Integrated pest risk management measures are used for the production and certification of plants that move in trade between Canada and the continental United States.

In Canada, the GCP replaced the Canadian Greenhouse Certification Program (CGCP) which was established in 1996.

The technical requirements and this directive must be used together. With the exception of high level statements to link the technical requirements with the administrative requirements, the details of the technical requirements are not repeated in this directive.

4.0 Scope

4.1 Regulated pests

The GCP is designed to prevent the spread of all pests regulated by APHIS and the CFIA.

For the purpose of the GCP, pests that are new to Canada and/or the continental United States are considered to be regulated until their regulatory status is determined. A pest is considered to be new when it is present in an area where it has not previously been known to exist.

4.2 Regulated articles

All plants grown at an Authorized Facility are subject to the conditions of the technical requirements, whether they are intended for shipment under the GCP or not. It is not a requirement of the GCP that every plant in production be eligible to become a GCP Certified Plant.

4.3 Regulated areas

Plants for planting may be entered into the GCP from any country of the world, provided that the plants are enterable into both Canada and the United States.

5.0 General requirements

Plants that can meet the phytosanitary import requirements of both Canada and the United States are eligible to be produced in and distributed under the GCP.

In Canada, facilities that sign a compliance agreement with the CFIA and operate their facilities in accordance with the GCP are authorized to ship greenhouse-grown plants to the United States under an export certification label in lieu of a CFIA-issued phytosanitary certificate. Certified Plants shipped under an interfacility stamp to other GCP facilities in Canada maintain their Certified status.

5.1 Clarification of specific elements of the GCP

A key objective of the GCP is consistent, equivalent application of the technical requirements at authorized facilities in Canada and the continental United States. To this end, APHIS and the CFIA co-developed the training units that were used to inform the inspector training developed by the CFIA, and the GCP Industry Training Program developed by Flowers Canada Growers.

The structure of the technical requirements takes into account that the CFIA and APHIS each have their own unique plant health regulations and administrative processes. The following subsections provide guidance for the administration of the GCP in Canada.

5.1.1 Authorized facilities

The list of GCP authorized facilities in Canada is found in Appendix 2.

5.1.1.1 Facilities with multiple distinct physical locations

With respect to GCP Part IV, Section 1.0: Facility authorization, a single authorized facility may include multiple distinct physical locations as long as certain conditions are met.

- The locations must have the same GCP manager and use the same administrative centre for issuance of GCP documentation and retention of GCP-specific records

When locations are not all within the service area of a single CFIA office, the CFIA will determine if the multiple locations may be considered to be a single authorized facility.

5.1.1.2 Seasonal and/or temporary off-site production

When facilities rent, lease or otherwise arrange for the use of an off-site production area that is not in the same physical location as the authorized facility and wish to include the off-site location in the GCP, the location and description of the off-site production area and the description of the management of the off-site facility must be included in the pest management plan. An off-site facility that is not included in the facility's pest management plan is not considered to be part of the authorized facility.

5.1.1.3 Shared premises

If an authorized facility is using a production area that is joined, shared, immediately adjacent to or otherwise not physically separated and separately managed from a production area used by another GCP authorized facility, and if 1 of the authorized facilities is suspended from the GCP, then all authorized facilities using the shared premises are suspended until the CFIA can complete an investigation and issues related to the suspension are addressed.

5.1.1.4 Not-authorized areas of a facility

If the greenhouse structure includes areas that are not considered to be part of the authorized facility, buffers may be utilized within the structure per the requirements of GCP Part IV, Section 2.2.1.3.

5.1.2 Official phytosanitary inspection

GCP Part II, Section 4.1.1 and Part IV, Section 2.1.3 provide options for facilities to obtain an official inspection.

The CFIA record of inspection will indicate all the following elements:

- the taxa verified and the quantity

- that the phytosanitary requirements of both Canada and the United States are met

- when the inspection was conducted

- who conducted the inspection

The record of official phytosanitary inspection provided by the CFIA may be either a:

- CFIA/ACIA 1337 Inspector's Report: Plant Protection Program

- invoice stamped by the CFIA

5.1.3 Authorized facility, plant broker

With respect to GCP Part I, Section 4.0, Glossary: authorized facility (plant broker), "producing plants" includes growing, holding in cold storage or otherwise maintaining plants. Facilities that for any reason hold plants longer than required to assemble a consignment must be authorized as an authorized facility (place of production).

With respect to GCP Part IV, Section 2.3, Compliance agreement elements for authorized facility: plant broker, "transform" includes the incorporation of associated articles, addition of growing media and any other practice that affects the phytosanitary risk of the exported plant. Facilities that "transform" plants must be authorized as a place of production.

5.1.4 Enterable

With respect to the use of the term "enterable" in the technical requirements, plants may be considered eligible for the GCP provided that they can meet the phytosanitary import requirements of both Canada and the United States. Plants from offshore, for example, plants that do not have a place of origin of Canada or the continental United States, must have phytosanitary documentation indicating that entry requirements for both countries are met.

GCP facilities must ensure that phytosanitary certificates for offshore plants include the additional declarations required by both APHIS and the CFIA.

5.1.4.1 Plant taxa that are eligible only if they are from a United States place of origin

The USDA Agricultural Commodity Import Requirements (ACIR) database indicate that some plant taxa are prohibited entry when their place of origin is Canada. The specific restrictions may include plants that are NAPPRA (not authorized pending pest risk analysis), plants subject to United States Federal Import Orders, and plants on the Prohibited Articles List.

These taxa may only be considered to be eligible plants when the following elements are met:

- the source of the plants is the United States

- APHIS and CFIA have developed minimum phytosanitary risk management measures that may be applied at a GCP authorized facility to maintain production conditions equivalent to those present in the United States

- authorized facilities that receive these taxa from the United States with the intent of returning the plants to the United States have a production module that incorporates the minimum phytosanitary risk management measures referenced in the previous bullet and has been accepted and incorporated into their pest management plan

5.1.5 Vegetable plants

According to GCP Part II, Section 3.0, Eligible plants: greenhouse-grown vegetable plants that include roots (for example "living lettuce") and require a phytosanitary certificate for export to the United States are eligible for the GCP.

5.1.6 CNCP interfacility stamp

For the purpose of GCP Part II, Section 4.1.1, Exceptions to the growth and monitoring period: a document bearing a Canadian Nursery Certification Program (CNCP) interfacility stamp is considered by Canada and the United States to be equivalent to a phytosanitary certificate issued for greenhouse-grown plants.

6.0 Specific requirements

6.1 Prohibitions

Plants may not be shipped under a GCP export certification label or interfacility stamp unless the plants meet all requirements of the GCP and this directive.

6.2 Import requirements

Plants may be imported from the continental United States under a GCP export certification label in lieu of a USDA-issued phytosanitary certificate.

An example of the USDA GCP export certification label is found in Appendix 4.

6.3 Domestic requirements

CFIA inspectors may use the GCP as a basis for determining that the requirements of Plant Protection Regulations sections 51 and 52 are met if the authorized facility has a suitable pest module(s) in place and its GCP authorization is not suspended.

6.4 Export requirements

Eligible plants meeting the conditions of the GCP at facilities authorized by the CFIA may be exported to the United States using a GCP export certification label in lieu of a CFIA issued phytosanitary certificate.

6.5 Audit requirements

The CFIA framework for organizing audit inspections is the Standard Inspection Procedure (SIP). Appendix 6 restates the GCP audit checklists (GCP Part V, Appendices 4 and 5) as they are organized within the SIP preventive control plan structure.

7.0 Administrative requirements

7.1 Authorization

Facilities that wish to participate in GCP must submit an application to their local CFIA office.

Facilities are authorized to ship certified plants under an export certification label in lieu of a phytosanitary certificate when they:

- successfully complete the authorization process

- enter into a compliance agreement with the CFIA

- are listed in the list of GCP authorized facilities in Canada

An overview of the authorization process is found in Appendix 1.

7.2 Compliance agreement

The GCP compliance agreement does not expire; however, there are circumstances under which a new GCP compliance agreement is required. These situations include but are not limited to:

- a change in facility ownership

- a significant change in the nature of the authorized facility's business, for example:

- a plant broker wishes to start producing plants

- the authorized facility changes geographic location

- there is a significant expansion or reduction of the physical dimensions of the authorized facility

- an authorized facility wishes to re-enrol in the GCP, following a voluntary withdrawal from the GCP

- an authorized facility has its authorization cancelled by the CFIA and the facility wishes to re-enrol in the GCP

Prior to entering into a new GCP compliance agreement, any prior GCP compliance agreements must be cancelled.

7.3 Authorization numbers, export certification labels and interfacility stamps

A unique authorization number will be issued to a facility when the CFIA acknowledges receipt of the application to participate in the GCP.

Administrative requirements for export certification labels and interfacility stamps are found in Appendix 3.

Specifications and examples of export certification labels and interfacility stamps are found in Appendix 4.

7.4 Forms

The forms used for the administration of the GCP are found in Appendix 5.

Facilities that do not have access to the Internet may request paper copies of the forms from their local CFIA office.

Facilities must verify with their local CFIA office how to submit their completed GCP administrative forms.

GCP forms may be transmitted electronically.

The completed form CFIA/ACIA 5793: Compliance Agreement for Authorized Facility, United States-Canada Greenhouse-Grown Plant Certification Program (GCP) requires a signature for both the authorized facility representative and CFIA.

All other GCP forms, when transmitted electronically, do not require a signature.

7.5 Records

To facilitate the ongoing review and maintenance of the GCP and regular communication between APHIS and CFIA, CFIA will maintain ongoing, cumulative summaries of GCP records for each authorized facility as specified in GCP Part III, Section 6.

8.0 Non-compliance

The GCP is a voluntary export certification option and facilities not meeting the requirements of their compliance agreement are subject to the corrective action, suspension and cancellation provisions of the GCP.

Some instances of non-compliance with the GCP compliance agreement may also be contraventions of the Plant Protection Act (PPA) or the Plant Protection Regulations (PPR). Examples of GCP non-compliance that are also contraventions of the PPA and PPR include:

- using an export certification label to ship plants or things which do not meet the requirements of the GCP

- using an export certification label to certify plants infested with a regulated pest

- failing to notify CFIA of the presence of a pest in an area where the pest has not previously been reported

9.0 References

9.1 Fees

The CFIA charges fees in accordance with the Canadian Food Inspection Agency Fees Notice. For information regarding fees, please contact your local CFIA office or visit the CFIA's Fees Notice website.

9.2 Supporting documents

D-96-20: Canadian Growing Media Program, Prior Approval Process and Import Requirements for Plants Rooted in Approved Media. CFIA, Ottawa.

D-01-06: Canadian phytosanitary policy for the notification of non-compliance and emergency action. CFIA, Ottawa.

CFIA Automated Import Reference System (AIRS)

USDA-APHIS Agricultural Commodity Import Requirements (ACIR)

Electronic Code of Federal Regulations, TITLE 7—Agriculture, Subtitle B—Regulations of the Department of Agriculture, Chapter III—Animal and Plant Health Inspection Service, Department of Agriculture, Part 319, Foreign Quarantine Notices, Subpart H 319.37 Plants for Planting and Part 360 Noxious Weed Regulations

ISPM 14. The Use of Integrated Measures in a Systems Approach for Pest Risk Management. 2002, FAO

ISPM 36. Integrated Measures for Plants For Planting. 2012, FAO

RSPM 5. NAPPO Glossary of Phytosanitary Terms. 2012, NAPPO Please scroll to RSPM #5

RSPM 24. Integrated Pest Risk Management Measures for the Importation of Plants for Planting into NAPPO Member Countries. 2005, NAPPO Please scroll to RSPM #24

Technical Requirements, United States – Canada Greenhouse-Grown Plant Certification Program

10.0 Appendices

Appendix 1: GCP authorization process

The GCP authorization process starts when a facility submits their application to participate in the GCP and is complete when the facility and the CFIA sign the compliance agreement. In between, there are a number of steps that both the facility and the CFIA must complete and the process is not always linear.

The following sections describe the authorization elements of the GCP. The GCP is designed to accommodate the wide range of business and production practices found in the greenhouse plant supply chain, ranging from importers, propagators and growers to shippers and brokers. Each facility needs to focus on the elements that apply to it. Facilities with more complex production and pest management practices may have more factors to consider.

Facilities are encouraged to complete the process steps as soon as possible. For example, the list of plants in production (Section 1.2) may be prepared in advance and may be submitted to the CFIA at the same time as the application.

GCP training and outreach for facilities

The GCP Industry Training Program for facilities participating in the GCP was created by Flowers Canada Growers in collaboration with QuébecVert.

The GCP Industry Training Program is available to all interested facilities.

Flowers Canada Growers is an independent third party and may establish fees for their services.

Persons interested in the GCP Industry Training Program should consult the Flowers Canada Growers GCP webpage or contact gcp@fco.ca.

1.0 Authorization for places of production

Note: all forms referenced in this section can be found in Appendix 5 of this directive, and also accessed through the CFIA Forms Catalogue.

1.1 Application

The completed application form must be submitted to the local CFIA office. Instructions are on the form.

1.2 List of plants in production

All place of production facilities must prepare and submit the list of plants in production. The list must meet the requirements of GCP Part IV, Section 2.2.2. The list may be submitted as a hard copy or as an electronic file that can be read by CFIA.

The CFIA will verify the list of plants in production and will inform the facility which regulated pests are present in the area and indicate the pests for which a pest module must be included in the pest management plan.

1.3 Pest modules

Pest module details are recorded in the pest management template in the section titled "GCP Part IV, Section 2.2.7.1 Pest modules'. If the details of the pest module are in a separate document, the location of the separate document must be noted.

1.4 Production modules

There are 4 circumstances in which a production module may be required:

- exemption from the minimum growth and monitoring period

- exemption for outdoor growth

- incorporation of associated articles

- production module required by the CFIA.

1.4.1 Exemption for growth and monitoring period of less than 28 days

GCP Part II, Section 4.1.1 lists the conditions when plants are excepted from the minimum 28 day growth and monitoring period.

For all other circumstances, when a facility wishes to produce certified plants in less than 28 days, an exemption is required (GCP Part II, Section 4.2.1). If the exemption is granted, the conditions of the exemption make up the production module. The link to the application for exemption is found in Appendix 5. The application is submitted to the local CFIA office and is forwarded to a CFIA-APHIS joint administration group for evaluation. The pest management plan must be submitted with the exemption request. The application for exemption should be submitted as soon as it is prepared as the response from the joint administration group is required before plants with a growth and monitoring period of less than 28 days may be included in the pest management plan.

1.4.2 Exemption for outdoor growth

When a facility wishes to produce certified plants outside the greenhouse structure for part of their production process, an exemption is required (GCP Part II, Section 4.2.2). If the exemption is granted, the conditions of the exemption make up the production module. The link to the application for exemption is found in Appendix 5. The application is submitted to the local CFIA office and it is forwarded to a CFIA-APHIS joint administration group for evaluation. The pest management plan must be submitted with the exemption request. The application for exemption should be submitted as soon as it is prepared as the response from the joint administration group is required before plants with a period of outdoor growth may be included in the pest management plan.

1.4.3 Incorporation of associated articles

When a facility produces certified plants that incorporate associated articles (for example, bamboo stakes) the details of how the facility obtains and maintains associated articles that can meet the phytosanitary import requirements of both APHIS and the CFIA are recorded in the pest management plan under the heading "GCP Part IV, Section 2.2.7.2 Production modules". Facilities should consult their local CFIA office about the current phytosanitary requirements for the associated article before the production module is designed.

1.4.4 Production module required by the CFIA

The CFIA may require a facility to incorporate a production module to detail specific risk mitigation measures. This production module could address risks identified by the inspector and not addressed elsewhere, or could address specific risk associated with a plant taxa, pest or country of origin. The CFIA inspector will determine whether this production module is necessary. If this module is required, it will be need to be added to the pest management plan under the heading "GCP Part IV, Section 2.2.7.2 Production modules".

1.5 Pest management plan

All places of production are required to use the pest management plan template found in Appendix 5.

The completed pest management plan is sent to the local CFIA office for review and acceptance. Once the pest management plan is accepted by the CFIA, the authorization audit is scheduled.

1.6 Authorization audit

Once the CFIA has received and accepted a facility's application for authorization, the list of plants in production and the pest management plan, an authorization audit will be scheduled to verify that all elements of the compliance agreement and pest management plan have been implemented at the facility. Deficiencies identified during the authorization audit must be addressed before a facility may enter into a GCP compliance agreement with the CFIA.

1.7 Compliance agreement

Following a successful authorization audit, the compliance agreement is prepared for signature. The compliance agreement will be signed by the legally authorized representative of the facility and the CFIA. Once the compliance agreement is signed, the facility is considered to be authorized and may operate under the conditions of the GCP technical requirements and D-16-02.

Newly authorized facilities may not ship under the GCP until they have their GCP export certification labels and/or interfacility stamps and their facility information is published on the list of GCP authorized facilities in Canada.

2.0 Authorization for plant brokers

2.1 Application

The completed application form must be submitted to the local CFIA office. Instructions are on the application form.

2.2 Authorization audit

Once the CFIA has reviewed and accepted a facility's application for authorization, an authorization audit will be scheduled to verify that all elements of the compliance agreement have been implemented at the facility. Deficiencies identified during the authorization audit must be addressed before a facility may enter into a GCP compliance agreement with the CFIA.

2.3 Compliance agreement

Following a successful authorization audit, the compliance agreement is prepared for signature. The compliance agreement will be signed by the legally authorized representative of the facility and the CFIA. Once the compliance agreement is signed, the facility is considered to be authorized and may operate under the conditions of the GCP technical requirements and D-16-02.

Newly authorized facilities may not ship under the GCP until they have their GCP export certification labels and/or interfacility stamps and their facility information is published on the list of GCP authorized facilities in Canada.

Appendix 2: GCP authorized facilities in Canada

| Authorization number | Authorized facility name | City/Town | Province |

|---|---|---|---|

| CAN-GCP-0041 | Jolly Farmer Products Inc. | Northampton | NB |

| CAN-GCP-0087 | K and K Greenhouses | Branchton | ON |

| CAN-GCP-0178 | Foliera Inc. | Beamsville | ON |

| CAN-GCP-0001 | Westwood Greenhouses Ltd. | New Hamburg | ON |

| CAN-GCP-0002 | Farm to Canada | Mississauga | ON |

| CAN-GCP-0003 | Rol-land Farms and Greenhouses Inc. | Blenheim | ON |

| CAN-GCP-0005 | Oasis Greenhouses Limited | Chatham | ON |

| CAN-GCP-0006 | Mucci Farms | Kingsville | ON |

| CAN-GCP-0007 | Lakeview Greenhouses and Farm Ltd. | Blenheim | ON |

| CAN-GCP-0008 | Albuna Plant Farm | Cottam | ON |

| CAN-GCP-0009 | Trillium Floral | St. Catharines | ON |

| CAN-GCP-0010 | Jeffery's Greenhouses Inc. | St. Catharines | ON |

| CAN-GCP-0011 | Northland Floral Inc. | Beamsville | ON |

| CAN-GCP-0012 | One Floral/ Seacliff Farms | Leamington | ON |

| CAN-GCP-0013 | Scharringa Greenhouses Ltd. | Waterdown | ON |

| CAN-GCP-0014 | Creekside Greenhouses Ltd. | Jordan Station | ON |

| CAN-GCP-0015 | Niagara Quality Flowers Ltd. | Fenwick | ON |

| CAN-GCP-0016 | Maple Grove Floral Inc. | Beamsville | ON |

| CAN-GCP-0019 | R. deVries Greenhouses | Niagara-on-the-Lake | ON |

| CAN-GCP-0020 | Wierenga Greenhouses Limited | Fenwick | ON |

| CAN-GCP-0022 | Regal Greenhouses Inc. | Virgil | ON |

| CAN-GCP-0023 | P. Ravensbergen & Sons Ltd. | Smithville | ON |

| CAN-GCP-0024 | Hillside Growers Inc. | Winona | ON |

| CAN-GCP-0025 | Schenck Farms & Greenhouses | St. Catharines | ON |

| CAN-GCP-0028 | Pioneer Flower Farms Limited | St. Catharines | ON |

| CAN-GCP-0029 | Kamps Greenhouses Inc. | Vineland Station | ON |

| CAN-GCP-0030 | Waldan Gardens | Wainfleet | ON |

| CAN-GCP-0031 | Bloom Depot Inc. | Hamilton | ON |

| CAN-GCP-0033 | Debono Greenhouses Ltd. | Waterford | ON |

| CAN-GCP-0034 | Aldershot Greenhouses Ltd. | Burlington | ON |

| CAN-GCP-0035 | Westbrook Greenhouses | Beamsville | ON |

| CAN-GCP-0036 | Harster Greenhouses Inc. | Hamilton | ON |

| CAN-GCP-0037 | Freeman Herbs | Beamsville | ON |

| CAN-GCP-0038 | Andrew Hendriks and Sons Greenhouses | Beamsville | ON |

| CAN-GCP-0039 | Spring Valley Gardens | St. Catharines | ON |

| CAN-GCP-0040 | Ontario Plants Propagation Limited | St. Thomas | ON |

| CAN-GCP-0042 | Whole Leaf Ltd. | Coaldale | AB |

| CAN-GCP-0044 | Trillium Hill Greenhouses | Grimsby | ON |

| CAN-GCP-0045 | Majestic Agriculture Inc. | Campbellville | ON |

| CAN-GCP-0046 | Richters Herbs | Goodwood | ON |

| CAN-GCP-0047 | Darvonda Nurseries Ltd. | Langley | BC |

| CAN-GCP-0048 | Meadowlands Horticultural Inc. | Burnaby | BC |

| CAN-GCP-0049 | Beamsville Garden Corp. | Beamsville | ON |

| CAN-GCP-0050 | Oriental Orchids Ltd. | Burnaby | BC |

| CAN-GCP-0052 | Kuyvenhoven Greenhouses Inc. | Brampton | ON |

| CAN-GCP-0053 | Bradford Greenhouses Ltd. | Bradford | ON |

| CAN-GCP-0054 | Fieldview Greenhouses Ltd. | Fenwick | ON |

| CAN-GCP-0056 | Burnaby Lake Greenhouses Ltd. | Surrey | BC |

| CAN-GCP-0057 | Vanderwees Greenhouses Inc. | Thunder Bay | ON |

| CAN-GCP-0058 | Cosmic Plants Inc. | Beamsville | ON |

| CAN-GCP-0059 | Great Lakes Floral | St. Catharines | ON |

| CAN-GCP-0061 | George Sant & Sons Ltd. | Kleinberg | ON |

| CAN-GCP-0062 | Distribution Frankarl Inc / Les Serres Régent Houle | Saint-Eustache | QC |

| CAN-GCP-0063 | Production Serres Yargeau inc. | Sherbrooke | QC |

| CAN-GCP-0064 | Homestead Growers Niagara Inc. | Vineland | ON |

| CAN-GCP-0065 | Mainland Floral Distributors Ltd. (B) | Aldergrove | BC |

| CAN-GCP-0066 | Adesso Services Ltd. | Aldergrove | BC |

| CAN-GCP-0068 | Nordic Nurseries Ltd. | Abbotsford | BC |

| CAN-GCP-0069 | Vaandrager Nurseries | Abbotsford | BC |

| CAN-GCP-0070 | Friends Farm Ltd. | Langley | BC |

| CAN-GCP-0071 | Misty Valley Growers Ltd. | Chilliwack | BC |

| CAN-GCP-0073 | Van Saane Greenhouses | Chilliwack | BC |

| CAN-GCP-0072 | Devan Greenhouses Ltd. | Abbotsford | BC |

| CAN-GCP-0074 | Berry's Tropicals | Dewdney | BC |

| CAN-GCP-0075 | C. Farms | Dewdney | BC |

| CAN-GCP-0077 | Clearview Horticulture Limited | Aldergrove | BC |

| CAN-GCP-0078 | EVL Nursery | Langley | BC |

| CAN-GCP-0079 | Westcan Greenhouses Ltd. | Langley | BC |

| CAN-GCP-0081 | Kralt Greenhouses Ltd. | Millgrove | ON |

| CAN-GCP-0080 | Genesis Plant Propagation Ltd. | Langley | BC |

| CAN-GCP-0083 | The Floral Express Inc. | Woodstock | ON |

| CAN-GCP-0088 | Linwell Gardens Ltd. | Beamsville | ON |

| CAN-GCP-0089 | Hunter Road Greenhouses Inc. | Niagara-on-the-Lake | ON |

| CAN-GCP-0091 | Colonial Florists Ltd. | St. Catharines | ON |

| CAN-GCP-0093 | Zomer's Greenhouses Inc. | Milton | ON |

| CAN-GCP-0094 | Les Serres Sylvain Cléroux Québec Inc. | Laval/Mirabel | QC |

| CAN-GCP-0095 | Taisuco Canada Agriculture Corporation | Abbotsford | BC |

| CAN-GCP-0097 | Qualitree Propagators Inc. | Rosedale | BC |

| CAN-GCP-0098 | Rainbow Greenhouses Inc. | Chilliwack | BC |

| CAN-GCP-0099 | Helianthus Holdings Inc. (DBA HortyGirl Living Decor) | Langley | BC |

| CAN-GCP-0101 | Ed Sobkowich Greenhouses Ltd. | Grimsby | ON |

| CAN-GCP-0102 | Foxwood Greenhouses Ltd. | Freelton | ON |

| CAN-GCP-0103 | Vos Floral Ltd. | Freelton | ON |

| CAN-GCP-0105 | Tropical Expressions | Hamilton | ON |

| CAN-GCP-0107 | De Goey's Nursery and Flowers | Wheatley | ON |

| CAN-GCP-0108 | G. Moody Greenhouse | Wheatley | ON |

| CAN-GCP-0109 | van Zanten Floral Inc. | Vineland | ON |

| CAN-GCP-0110 | Orchid Greens | Toronto | ON |

| CAN-GCP-0111 | Xborder Trucking | Wainfleet | ON |

| CAN-GCP-0112 | Westland Greenhouse GB Inc. | Grand Bend | ON |

| CAN-GCP-0113 | Roelands Plant Farms Inc. | Lambton Shores | ON |

| CAN-GCP-0114 | Flora Pack Inc. | St. Catharines | ON |

| CAN-GCP-0115 | Boekestyn Greenhouses | Jordan Station | ON |

| CAN-GCP-0116 | Colasanti Farms Ltd. | Kingsville | ON |

| CAN-GCP-0118 | Rainbow Greenhouses Alberta Inc. | Iron Springs | AB |

| CAN-GCP-0120 | Hillside Greenhouses | Niagara-on-the-Lake | ON |

| CAN-GCP-0121 | Dutch Flower House Inc. | Niagara-on-the-Lake | ON |

| CAN-GCP-0122 | Sunrise Greenhouses Ltd. | Vineland Station | ON |

| CAN-GCP-0123 | Vermeer Greenhouses (Welland) Inc. | Welland | ON |

| CAN-GCP-0124 | Gregory Greenhouses Inc. | St. Catharines | ON |

| CAN-GCP-0125 | Van Hoffen Farms (1999) Ltd. / Maple Crest Farms | Grassie | ON |

| CAN-GCP-0126 | Janus Gardens Inc. | Aldergrove | BC |

| CAN-GCP-0127 | Gregory Floral Inc. | St. Catharines | ON |

| CAN-GCP-0128 | Scania Greenhouses Ltd. | Langley | BC |

| CAN-GCP-0129 | J.M. Lacroix et fils Inc. | Laval | QC |

| CAN-GCP-0130 | Willy's Greenhouse Ltd. | Niagara-on-the-Lake | ON |

| CAN-GCP-0133 | Fraser Valley Nursery | Aldergrove | BC |

| CAN-GCP-0134 | Morgan Creek Tropicals Ltd. | Surrey | BC |

| CAN-GCP-0135 | Noël Wilson Inc. | Saint-Rémi | QC |

| CAN-GCP-0136 | Willy Haeck et Fils Inc. | Saint-Rémi | QC |

| CAN-GCP-0137 | Proplant Propagation Services Ltd. | Jarvis | ON |

| CAN-GCP-0138 | La Ferme Grover Inc. | Laval | QC |

| CAN-GCP-0139 | Meyers Fruit Farm Limited | Niagara-on-the-Lake | ON |

| CAN-GCP-0140 | Meyers Flowers | Niagara-on-the-Lake | ON |

| CAN-GCP-0141 | Horbach's Farms and Greenhouse | Niagara-on-the-Lake | ON |

| CAN-GCP-0142 | UFG Cooperative Association | Burnaby | BC |

| CAN-GCP-0143 | Les Serres Frank Zyromski Inc. | Rivière-Rouge | QC |

| CAN-GCP-0144 | West Coast Floral Growers and Distributors Ltd. | Surrey | BC |

| CAN-GCP-0146 | Bevo Farms Ltd. | Langley | BC |

| CAN-GCP-0147 | Fernlea Flowers Ltd. | Delhi | ON |

| CAN-GCP-0148 | Sedum Master Inc. | Princeton | ON |

| CAN-GCP-0149 | Orchard Park Growers | St. Catharines | ON |

| CAN-GCP-0150 | Les Serres Oli-Ève Charbonneau SENC | Saint-Eustache | QC |

| CAN-GCP-0151 | The Arbory Ltd. | Jordan Station | ON |

| CAN-GCP-0153 | Midway Farm Market and Greenhouses | Jordan Station | ON |

| CAN-GCP-0154 | Les serres Mario et Dominic Lacroix Inc. | Laval | QC |

| CAN-GCP-0155 | European Planters Inc. | Niagara-on-the-Lake | ON |

| CAN-GCP-0156 | DeVry Greenhouses Ltd. | Chilliwack | BC |

| CAN-GCP-0157 | Voogt Greenhouses Limited | Niagara-on-the-Lake | ON |

| CAN-GCP-0158 | Serres Pierre Houle | Mirabel | QC |

| CAN-GCP-0160 | Les Serres Jean-Marc Joly | Mirabel | QC |

| CAN-GCP-0162 | Waldan Gardens Wholesale | Wainfleet | ON |

| CAN-GCP-0163 | Pure Horticulture Inc. | Saint-Rémi | QC |

| CAN-GCP-0164 | Jacques Lauzon et fils Inc. | Laval | QC |

| CAN-GCP-0166 | Flower Group Operating Inc./One Floral Group | Jordan Station | ON |

| CAN-GCP-0167 | Tropica Aquarium Plants | North Vancouver | BC |

| CAN-GCP-0168 | Nagra Greenhouses Ltd. | Coquitlam | BC |

| CAN-GCP-0171 | Floral Dimensions | Fenwick | ON |

| CAN-GCP-0172 | Greenfield Gardens Inc. | Fenwick | ON |

| CAN-GCP-0173 | TD Greenhouses Ltd. | Wainfleet | ON |

| CAN-GCP-0175 | J. Hong Farms | Surrey | BC |

| CAN-GCP-0176 | Niagara Flower Growers | Niagara-on-the-Lake | ON |

| CAN-GCP-0177 | Brookdale Treeland Nurseries – Valleybrook Farm | Niagara-on-the-Lake | ON |

| CAN-GCP-0179 | Dykstra Greenhouses | St. Catharines | ON |

| CAN-GCP-0180 | Bayview Flowers | Jordan Station | ON |

| CAN-GCP-0181 | Bayview Greenhouses Jordan #1 | Jordan Station | ON |

| CAN-GCP-0182 | Bayview Greenhouses Jordan #2 | Jordan Station | ON |

| CAN-GCP-0183 | Westland Greenhouses (Jordan) Ltd. | Jordan Station | ON |

| CAN-GCP-0185 | Lunfus Inc. | Welland | ON |

| CAN-GCP-0186 | Slappendel Greenhouses Inc. | Fenwick | ON |

| CAN-GCP-0187 | Waterview Farms | Vineland Station | ON |

| CAN-GCP-0189 | Les Jardins Hemmingford 2020 Inc. | Hemmingford | QC |

| CAN-GCP-0190 | Frisia Flora Greenhouses | Beamsville | ON |

| CAN-GCP-0191 | Les Serres AML Dauphinais Inc | Hemmingford | QC |

| CAN-GCP-0192 | United Floral Distributors | Fenwick | ON |

| CAN-GCP-0193 | Scott Street Greenhouses Ltd. | St. David's | ON |

| CAN-GCP-0194 | François Dauphinais | Lacolle | QC |

| CAN-GCP-0195 | Pan American Nursery Products Inc. | Surrey | BC |

| CAN-GCP-0196 | Pan American Nursery Products Inc | Niagara-on-the-Lake | ON |

| CAN-GCP-0197 | Hanemaayer Greenhouses Ltd. | Vineland | ON |

| CAN-GCP-0198 | Van Egmond & Sons Greenhouses | St. Catharines | ON |

| CAN-GCP-0199 | Greenex International, Inc. | St. Catharines | ON |

| CAN-GCP-0200 | Berkelbloem Inc. | Simcoe | ON |

| CAN-GCP-0202 | Van Zanten Greenhouses | Pelham | ON |

| CAN-GCP-0206 | Fil Growers Limited | Newmarket | ON |

| CAN-GCP-0208 | Production Frankarl inc. | Saint-Eustache | QC |

| CAN-GCP-0209 | Les Jardins Rivière la Guerre | St-Anicet | QC |

| CAN-GCP-0211 | ABC Plants Inc. | Montréal | QC |

| CAN-GCP-0212 | Houweling's Nurseries Limited | Delta | BC |

| CAN-GCP-0213 | Sand Plain Gardens | Simcoe | ON |

| CAN-GCP-0216 | Scenic Floral Inc. | Beamsville | ON |

| CAN-GCP-0218 | Genson Quality Plants Inc. | Kingsville | ON |

| CAN-GCP-0219 | Exemplar Horticulture Ltd. | Abbotsford | BC |

| CAN-GCP-0220 | Green Flora Greenhouses | Abbotsford | BC |

| CAN-GCP-0221 | Sylvan Vale Nursery | Black Creek | BC |

| CAN-GCP-0222 | Ontario Plants Propagation Limited - Glencoe | Glencoe | ON |

| CAN-GCP-0223 | Country Tropicals Inc. | Newcastle | ON |

| CAN-GCP-0224 | Liberty Tropicals LTD. | Grimsby | ON |

| CAN-GCP-0225 | Westland Direct Inc. | Courtland | ON |

| CAN-GCP-0227 | Sonnyside Flowers Ltd. | Delhi | ON |

Appendix 3: Administrative requirements for export certification labels and interfacility stamps

General requirements

Subject to the requirements of this appendix, authorized facilities may obtain export certification labels and interfacility stamps from the supplier of their choice.

At the time of receipt, facilities must verify that export certification labels and interfacility stamps meet the technical specifications found in Appendix 4.

Facilities must maintain a current inventory of export certification labels and interfacility stamps through their life cycle.

Specific requirements

Export certification labels

- Authorized Facilities may not manufacture export certification labels

- Export certification labels must be commercially manufactured

- The facility authorization number and the unique sequential serial numbers must be pre-printed on the export certification labels

- Export certification labels must meet the specifications found in Appendix 4

- The serial number of the first label will be 000001

- When additional labels are ordered, the first serial number must immediately follow the last serial number of the previous order

- There is to be only 1 original label for each serial number. If duplicate labels are required to meet business needs, the duplicate label must be preprinted with "copy – copie" as illustrated in Appendix 4, Section 1.1

- Export certification labels should be used in sequential order. Variation may be accepted by prior arrangement with CFIA

- Spoiled labels and any unused duplicate copies must be maintained for verification until the CFIA inspector indicates they may be disposed of and concurs with the manner of disposal

Interfacility stamps

- Authorized Facilities may not manufacture interfacility stamps

- Interfacility stamps must be commercially manufactured

- Interfacility stamps must meet the specifications found in Appendix 4

- Worn out stamps must be maintained for verification until the CFIA inspector indicates they may be disposed of and concurs with the manner of disposal

Records

The following details must be included in the facility's records:

- Per GCP Part IV, Section 2.1.3, GCP Certification Documents

- Designated individual who maintains control of labels and stamps

- Authorized personnel who may access and use labels and stamps

- For each batch of export certification labels ordered and received:

- Manufacturer

- Date of receipt

- Range of serial numbers received

- Verification that the order meets the specifications found in Appendix 4

- For individual export certification labels:

- The facility must be able to demonstrate how each export certification label is used, including if a label is spoiled/ void

- When a facility uses duplicate export certification labels, each duplicate label must be accounted for

- For each interfacility stamp ordered and received:

- Manufacturer

- Date of receipt

- Verification that the interfacility stamp received meets the specifications found in Appendix 4

- Date and manner of disposal for each retired interfacility stamp

Appendix 4: Specifications and examples of export certification labels and interfacility stamps

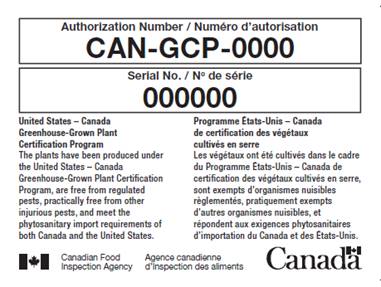

1.0 Export Certification Label, Canada

Download the Export Certification Label and fill in the Authorization number and Serial number using 22 point bold Helvetica or Arial font.

Description of export certification label

The Export Certification Label is a rectangular sticker

All the information on the Export Certification Label is present in both official languages

The facility authorization number appears on the top line of the sticker

The second line of the sticker is the unique serial number

The middle of the sticker is headed "United States – Canada Greenhouse-Grown Plant Certification Program" followed by the phytosanitary declaration: "The plants have been produced under the United States – Canada Greenhouse-Grown Plant Certification Program, are free from regulated pests, practically free from other injurious pests, and meet the phytosanitary import requirements of both Canada and the United States."

The bottom line of the sticker starts with a Canada flag, followed by Canadian Food Inspection Agency and followed by the word Canada with a small Canada flag over the final "a"

Label specifications

Paper: white, permanent adhesive label

Size: 10.16 cm wide by 7.62 cm high (4 inches wide by 3 inches high), no bleed

Ink type: permanent. Labels that smear are considered noncompliant.

Ink colour: 100% Black (or C=0 M=0 Y=0 K=100%)

Font for the Authorization number and Serial number: 22 point bold, Helvetica or Arial.

Facilities found to be using GCP export certification labels that do not meet the specifications of this section will be assessed a minor noncompliance and the noncompliant export certification labels must be surrendered to or disposed of with the concurrence of CFIA.

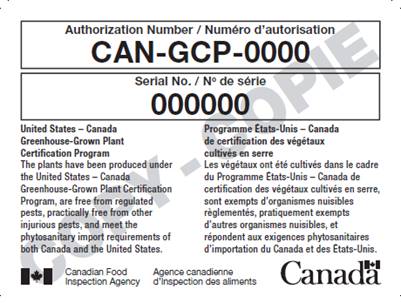

1.1 Export Certification Label, Canada, duplicate version

Facilities whose business practices require a duplicate copy of the export certification label may use the following template.

Download the duplicate version of the Export Certification Label and fill in the authorization number and serial number using 22 point bold Helvetica or Arial font.

Description of export certification label with "copy-copie" wordmark

The Export Certification Label is a rectangular sticker

All the information on the Export Certification Label is present in both official languages.

The facility authorization number appears on the top line of the sticker

The second line of the sticker is the unique serial number

The middle of the sticker is headed "United States – Canada Greenhouse-Grown Plant Certification Program" followed by the phytosanitary declaration: "The plants have been produced under the United States – Canada Greenhouse-Grown Plant Certification Program, are free from regulated pests, practically free from other injurious pests, and meet the phytosanitary import requirements of both Canada and the United States."

The bottom line of the sticker starts with a Canada flag, followed by Canadian Food Inspection Agency and followed by the word Canada with a small Canada flag over the final "a"

The text on the sticker is overlaid diagonally with "copy – copie"

Label specifications

Label specifications are the same as for the original export certification label shown in Section 1.0 above, with the exception that the duplicate may be proportionally scaled down to meet the facility's business needs.

2.0 Interfacility Stamp, Canada

Download the Interfacility Stamp and fill in the authorization number using 22 point bold Helvetica or Arial font.

Description of interfacility stamp

All the information on the interfacility stamp is present in both official languages

The top left of the stamp is the Canada flag

The top line of the stamp states "Canadian Food Inspection Agency"

The body of the stamp states "United States – Canada Greenhouse-Grown Plant Certification Program" and "Interfacility stamp". Underneath is written the facility authorization number.

The bottom right corner of the stamp states "Canada" with a small Canada flag over the final "a".

Stamp specifications

Stamps may be self-inking or may be used with a stamp pad.

Size: 15.24 cm wide by 7.62 cm high (6 inches wide by 3 inches high). The stamp size may be proportionally scaled down to a minimum 7.62 cm high by 3.81 cm high (3 inches wide by 1.5 inches high) to meet the facility's business needs.

Ink type: permanent

Ink colour: black

Font for the authorization number: 22 point bold, Helvetica or Arial

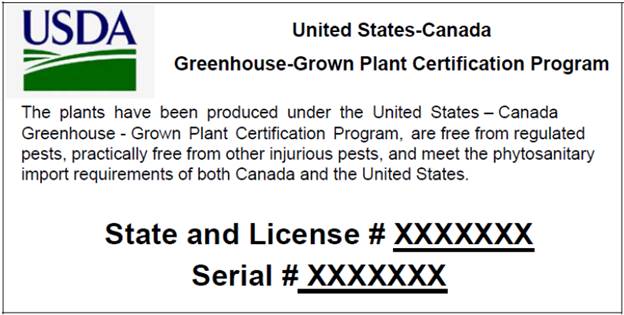

3.0 Export Certification Label, United States

Description of export certification label – United States

The Export Certification Label is a rectangular sticker

At the top of the label is the USDA symbol followed by "United States-Canada Greenhouse-Grown Plant Certification program"

The middle of the sticker is headed "United States – Canada Greenhouse-Grown Plant Certification Program" followed by the phytosanitary declaration "The plants have been produced under the United States – Canada Greenhouse-Grown Plant Certification Program, are free from regulated pests, practically free from other injurious pests, and meet the phytosanitary import requirements of both Canada and the United States."

The facility authorization number appears at the bottom of the sticker

The last line of the sticker is the unique serial number

Appendix 5: Forms

All forms referenced in this appendix may also be accessed through the CFIA Forms Catalogue.

1.0 Application to Participate in the United States – Canada Greenhouse-Grown Plant Certification Program (GCP)

Applications are submitted to the local CFIA office. Please contact your local office for details regarding how they would like to receive the application.

The application form can be found at:

2.0 Compliance agreement

The compliance agreement may be prepared by the facility or by the local CFIA office. The local CFIA inspector will determine who will prepare the compliance agreement and when it should be prepared.

The compliance agreement can be found at:

3.0 Pest management plan template

The pest management plan is a prerequisite for authorization of a facility, place of production. The CFIA will review the pest management plan as part of the authorization process and the ongoing audit process following authorization. The completed pest management plan is submitted to the local CFIA inspection office. Please contact your local office when you are ready to submit your complete pest management plan.

For convenience of facilities, the CFIA has prepared a pest management plan template in a fillable PDF format that can be found at:

Alternatively, facilities may prepare their pest management plan using the software of their choice. The plan must be typed and follow the same headings and content as the ".pdf Pest Management Plan Template". Standardized third party pest management plan templates that meet the requirements of this section may also be used, for example the template provided in the GCP end-user training developed by Flowers Canada Growers.

For reference, the following are the headings and elements that must be included in the facility's pest management plan.

Content and layout instructions

Supplemental documents may be used to complete or add detail to individual sections of the pest management plan.

When a supplemental document is included in the pest management plan, it may either be incorporated directly or included by reference by indicating the name of the document and its location under the appropriate heading(s).

Supplemental documents referenced in this pest management plan are considered to be part of the pest management plan for the purpose of the GCP compliance agreement.

The title of the pest management plan is:

Pest Management Plan

United States - Canada Greenhouse-Grown Plant Certification Program

Section 1 Facility and contact information

- facility name

- authorization number

Mailing address

- address

- city

- province

- postal code

- telephone number

- fax number

- email address

Physical address

- street address

- city

- province

- postal code

Content and layout instructions

Physical address information is required for each location included under the facility authorization. Indicate if a location map is attached. If the facility is maintaining the Pest

Management Plan in electronic format, locations of maps and other supplemental information must be indicated under the applicable headings.

- brief description of the business (for example, propagation of plants from seed for sale as pre-finished plants, propagation of ornamental plants from domestic and offshore cuttings for distribution to retail etc.)

- prepared by (name of author).

GCP manager

- last name

- first name

- signature

- date

Content and layout instructions

A signature is optional for facilities maintaining the GCP pest management plan in electronic format.

Section 2 Amendment record

For each amendment, indicate:

- the amended section and content

- that the changes are approved by the facility representative

- the date it was approved

- whether CFIA was notified or not

Section 3 Management, designated personnel and key functions

- title

- name

Content and layout instructions

The minimum personnel to be listed include owner, GCP manager and alternate GCP manager.

The pest management plan may include additional personnel as desired.

Section 4 Regulated pests present in area or regulated pests that would trigger an additional declaration if a phytosanitary certificate was issued (supplied by CFIA)

For each pest, indicate:

- scientific name

- local common name

- host plants in production (yes/no)

- module required (yes/no)

Section 5 Pest management plan details

Preventive Control Plan (PCP) Sub-element 1.1 Incoming plants, inventory control and production practices

GCP Part IV, Section 2.2.2 List of plants in production

- briefly describe how you determine that plants entering the authorized facility are eligible plants

GCP Part IV, Section 2.2.5.1 Incoming plants

- describe the receiving process for incoming plants, including pest detection methods. Include a reference to where a list of designated personnel may be found

GCP Part IV, Section 2.1.2 Inventory control

- briefly describe how certified plants, non-conforming plants and ineligible plants are differentiated in the authorized facility

GCP Part IV, Section 2.2.1.4 Separation of ineligible plants

- indicate if eligible and ineligible plants of the same taxa are or are not grown at the facility

- if eligible and ineligible plants of the same taxa are grown at the facility, describe the system used to maintain plant identity and manage pest risk

Content and layout instructions

If the CFIA requires specific measures, go to the heading titled GCP Part IV, Section 2.2.7.2 Production modules, create an entry for "additional safeguarding prescribed by the CFIA" and describe the measures there.

GCP Part IV, Section 2.2.1.5 Separation of plants that have not completed the growth and monitoring period

Content and layout instructions

If the CFIA requires specific measures, go to the heading titled GCP Part IV, Section 2.2.7.2 Production modules, create an entry for "additional safeguarding prescribed by the CFIA" and describe the measures there.

Although there is no content required under this heading, include it in the pest management plan for consistency with the .pdf Pest Management Plan Template provided by the CFIA.

GCP Part IV, Section 2.2.1.1 Protection from soil-borne pests

- describe all media used in the production of plants; include the name of the manufacturer

Content and layout instructions

If there are regulated soil-borne pests in the area where the facility is located, the management practices to prevent contamination must be included in the appropriate pest module under heading GCP Part IV, Section 2.2.7.1 Pest modules.

GCP Part IV, Section 2.2.7.2 Production modules

Content and layout instructions

There are 5 types of production modules that may be included in the pest management plan:

- growth and monitoring less than 28 days

- outdoor growth

- associated articles

- additional safeguarding prescribed by the CFIA

- special

The layout for each type of production module is described below. Production modules are to be included in the pest management plan as appropriate. If there are multiple distinct production modules of the same type (for example, the facility uses multiple types of associated articles), create a separate production module for each situation. When a production module is no longer required, it may be removed from the Pest Management Plan.

Note: the "special" module option is reserved for future programs/ initiatives that may be administered under the GCP. Instructions describing the production module will be included in the program/ initiative details.

Production module: Growth and monitoring less than 28 days

- describe the additional risk mitigating measures

Production module: Outdoor growth

- describe the authorized outdoor production area(s) in relation to the authorized facility

- the authorized outdoor production area(s) should be shown on the facility map or diagram

- describe the additional risk mitigating measures

Production module: Associated articles

- describe the associated article

- describe the process for ensuring that the associated article is enterable into both the United States and Canada and for maintaining identity while in the authorized facility

Production module: Additional safeguarding prescribed by the CFIA

- details

Production module: Special

- details

PCP Sub-element 1.4 Inspection and verification of certified plants

GCP Part IV, Section 2.2.5.3 Shipping inspection of certified plants

- describe the inspection procedure, including pest detection methods

- include a reference to where a list of designated personnel may be found

- describe the process for verifying that plants shipped under and export certification label or interfacility stamp are certified plants

PCP Sub-element 2.2 Pest detection and pest control

GCP Part IV, Section 2.2.5 Pest detection and pest control

- describe the actions to be taken when there is a significant pest find, including notification per Part IV, Section 2.1.5 of the GCP technical requirements

- describe the activity records maintained related to pest scouting, plant inspections, control procedures, pest identifications and laboratory submissions

GCP Part IV, Section 2.2.5.2 Examination of production areas

- describe procedures and practices for pest detection, including official pest scouting, frequency, intensity, pest detection methods, etc.

- include a reference to where a list of designated personnel may be found

- describe how scouting activities are documented

GCP Part IV, Section 2.2.7.1 Pest modules

Content and layout instructions

A pest module must be developed for each pest listed in Section 4 where the requirement for a pest module is "yes".

Pest module

For each pest, indicate:

- scientific name

- local common name

- host plants in production (list). If the control strategies are applied to all plants in production "all" may be indicated

- describe how pest information is shared with appropriate staff, including life cycle, distribution, damage, host(s), identification guide, pictures etc.

- describe control strategy(ies) used to prevent spread of this pest

PCP Sub-element 5.1 Description of greenhouse and production areas

GCP Part IV, Section 2.2.1 Minimum requirements for greenhouse structures and production practices

- describe the facility, including a description of physical structure, for example, glasshouse, screenhouse etc. and the area under production

- include a map or diagram of the facility showing all locations for handling plants, for example, receiving, propagation, coolers

- the description of the various parts of the facility may be shown on the map or diagram

- pictures, aerial photographs etc. may be used for clarity

GCP Part IV, Section 2.2.1.2 Protection from non-irrigation water and water-borne pests

- describe the source of irrigation water and any treatment if applicable

Content and layout instructions

If there are regulated water-borne pests in the area where the facility is located, the management practices to prevent contamination must be included in the appropriate pest module under heading GCP Part IV, Section 2.2.7.1 Pest modules.

GCP Part IV, Section 2.2.1.3 Minimum requirements for greenhouse structures and production practices

- describe any buffer areas around the facility and how they are managed

GCP Part IV, Section 2.2.1.6 Exemption for outdoor production

- see PCP sub-element 1.1, GCP Part IV, Section 2.2.7.2 Production modules

Content and layout instructions

If an exemption for outdoor production is in place, go to the heading titled GCP Part IV, Section 2.2.7.2 Production modules and create an entry for "Exemption for outdoor production".

Although there is no content required under this heading, include it in the pest management plan for consistency with the .pdf pest management plan template provided by the CFIA.

4.0 Request for exemption

2 exemption request forms have been standardized and are available in a fillable PDF format. Similar forms are used by GCP facilities in the United States.

The completed request for exemption is submitted to the local CFIA office. The pest management plan must be submitted with the exemption request.

The local office will triage the request and may return it for more information.

The exemption request will be considered by an APHIS-CFIA joint administration group.

The exemption request may be;

- accepted, or

- denied, or

- accepted subject to additional conditions. If the additional conditions are not implemented by the facility, the request for exemption is denied.

Exemption requests that are accepted will be incorporated into the facility's pest management plan as a production module.

Appendix 6: GCP audit inspections under the CFIA Standard Inspection Procedure

The GCP is audited using the CFIA Standard Inspection Procedure (SIP) as the framework for conducting GCP audit inspections.

The following tables are extracted from the Operational Guidance that is given to CFIA inspectors to guide delivery of the GCP. The phytosanitary risk management measures from the GCP Compliance Agreement are grouped under the SIP audit structure. Authorized facilities reviewing their SIP audit report can use these tables to relate the feedback in the audit report to the audited sections of their GCP Compliance Agreement.

Note: if the same or similar phytosanitary risk management measures appear under multiple headings in the GCP Compliance Agreement, they may have been grouped into a single item under the SIP framework.

1. Audit framework for places of production

1.1 Preventive Control Plan (PCP) sub-element 1.1(a) The process is controlled to achieve regulatory compliance.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | Pest management plan 2.2.6 |

Is the pest management plan current? Has the facility notified CFIA of any amendments to the pest management plan? |

| 2 | Plant list 2.2.2 and its subparts 2.2.2.1 2.2.2.2 2.2.2.3 2.2.2.4 |

Is a current list of all plants in production at the facility maintained:

|

| 3 | Plant list 2.2.2 |

Does the system described in the pest management plan support the desired outcome to ensure that the facility can adequately describe how plants will qualify under the GCP? |

| 4 | Eligible plants 2.2.3 Records 2.1.4 |

Which records are maintained to demonstrate eligibility to enter the GCP? Which records will include source of plants? Which records will show dates and growth stage of plants that entered the facility? For eligible plants from third countries, which records will indicate plants meet U.S. size-age requirements at the time of entry to Canada or the continental United States? Which records include date and growth stage when certified plants are shipped? |

| 5 | Incoming plants 2.2.5.1 Protection from soil borne pests 2.2.1.1 |

Are incoming plants inspected prior to moving into production areas? Do plants entering in growing media from other than the continental United States or Canada meet the requirements of both jurisdictions' growing media programs? |

| 6 | Inventory control 2.1.2 |

Does the system described in the pest management plan support the outcome to ensure that product identity will be maintained? |

| 7 | Separation of ineligible plants 2.2.1.4 |

Are there plants grown at the facility that are of the same taxa and both eligible and ineligible? Is the system that is in place to maintain their identity and segregation robust enough? |

| 8 | Separation of plants not completing growth and monitoring 2.2.1.5 |

Are the plants that require a 28 day growth & monitoring period separated in a manner commensurate with pest risk (for example, pest risk associated with the specific taxa and origin)? |

| 9 | Control of non- conforming plants 2.1.2.1 |

Does the system described in the pest management plan support the outcome of ensuring that non-conforming plants will be identified, inventoried and handled in a manner that ensures they are not shipped under the GCP, and that the plants will not contaminate, infest or become mixed with plants grown/shipped under the GCP? |

| 10 | Protection from soil and soil-borne pests 2.2.1.1 |

Does the description in the facility's pest management plan include a step to verify that the growing media is free from regulated pests? |

| 11 | Protection from soil and soil-borne pests 2.2.1.1 |

Do the measures that the facility has in place ensure that growing media will be managed to preclude contamination by regulated soil-borne pests? |

| 12 | Production modules 2.2.7.2 Exemption for outdoor production 2.2.1.6 |

Have production modules for outdoor production been accepted by the CFIA/joint administration group? Have the mitigation measures described in the production modules for outdoor production been implemented? |

| 13 | Production module 2.2.7.2 |

Have production modules for the exemption from the 28 day growth and monitoring period been accepted by the CFIA/joint administration group? |

| 14 | Production module 2.2.7.2 |

Have the measures described in the production modules for associated articles been implemented? |

| 15 | Production module 2.2.7.2 Separation of ineligible plants 2.2.1.4 (when applicable) |

Does the system described in the pest management plan ensure that eligible and ineligible plants of the same taxa are identified? Are plants separated sufficiently to manage pest risk? |

| 16 | Production module 2.2.7.2 Separation of plants that have not completed the growth and monitoring (when applicable) |

Are the plants that have not completed the growth and monitoring period and that pose a risk are sufficiently identified to manage the risk? |

| 17 | Notifying the NPPO 2.1.5 |

If there is a pest find of significance or there is a situation that is considered a critical noncompliance, will the GCP manager stop shipping the affected certified plants until advice is received from the CFIA? The facility has a process where CFIA will be notified when there is a presence or suspected presence of any condition or situation that may be considered a critical noncompliance at the facility or in association with product purchased or sold, and when there are changes in ownership or the GCP manager. |

1.2 PCP sub-element 1.4 Exported commodities meet foreign country import requirements and conditions and Canadian export requirements, where applicable.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | GCP certification documents 2.1.3 | Who has been designated to maintain control of export certification labels and interfacility stamps? |

| 2 | GCP certification documents 2.1.3 | How are export certification labels and interfacility stamps stored securely? How does the facility ensure that labels and stamps are accessed and used only by trained, authorized personnel and not shared with other facilities? |

| 3 | GCP certification documents 2.1.3 | How does the facility ensure that export certification labels and interfacility stamps will not be used for purposes other than shipping plants from the authorized facility's premises? |

| 4 | GCP certification documents 2.1.3 | Does the documentation accompanying GCP shipments include the destination, the quantity of certified plants and the scientific name of each plant in the consignment with plants identified to genus, and to species/cultivar if required by regulation? |

| 5 | GCP certification documents 2.1.3 | How does the documentation clearly link the certified plants to the export certification label or interfacility stamp? |

| 6 | GCP certification documents 2.1.3 | How does the facility ensure that the documentation for mixed planters, hanging baskets, tropical baskets, etc. will include identification of all plant taxa? |

| 7 | GCP certification documents 2.1.3 | How does the facility ensure that when mixed planters include plants that are eligible but not certified, there is an official phytosanitary inspection conducted and kept on record? |

| 8 | GCP certification documents 2.1.3 | The CFIA must be contacted if export certification labels or interfacility stamps are lost or stolen. |

| 9 | Export certification label 2.1.3.1 | How does the facility ensure that the Export Certification Labels are affixed to an appropriate document with the required information: destination, quantity of certified plants, scientific name of each plant in the consignment? |

| 10 | Export certification label 2.1.3.1 | How does the facility ensure a separate Export Certification Label is used for each separate consignee? |

| 11 | Export certification label 2.1.3.1 | Export Certification Labels are used for United States exports only. |

| 12 | Interfacility stamp 2.1.3.2 | How does the facility ensure that the interfacility stamp is applied only to shipping documents for plants shipped domestically to another authorized facility? |

| 13 | Inventory control 2.1.2 Records 2.1.4 |

How does the facility demonstrate that only eligible plants are used to produce certified plants? How does the facility demonstrate that only certified plants are shipped under an Export Certification Label or interfacility stamp? How do records demonstrate that certified plants meet the conditions of the GCP? |

| 14 | Shipping inspection of Certified Plants 2.2.5.3 | How does the facility ensure that certified plants are inspected to verify freedom from regulated pests? |

| 15 | Records 2.1.4 | Availability of records during audits. |

| 16 | Records 2.1.4 | Minimum 3 year record retention period. |

| 17 | Records 2.1.4 | Do records include the date of the activity, name of designated person, and specific information related to the activity, as well as additional comments or notes describing any deviations? |

1.3 PCP sub-element 2.2 An effective control program for pests, including vectors, is in place to prevent entry, to detect and eliminate pests and to prevent contamination of the commodity.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | Examination of production areas 2.2.5.2 |

Are procedures to scout all production areas implemented as per the facility's Pest Management Plan? Are these conducted at a minimum 2 week interval? |

| 2 | GCP manager 2.2.4 |

How does the GCP manager ensure that facilities are monitored and maintained and production areas are monitored to verify freedom from regulated pests? |

| 3 | Pest detection and control 2.2.5 |

Are records related to scouting (pest monitoring), inspections, control procedures, pest identification and laboratory submissions maintained as per the Pest Management Plan? |

| 4 | Pest detection and control 2.2.5 |

Are there procedures to take control measures immediately should regulated pests be detected? (Immediately means that steps are taken as soon as notification is received to control or mitigate the pest and a control plan is developed. |

| 5 | Pest modules 2.2.7.1 Protection from soil and soil-borne pests 2.2.1.1 Irrigation and protection from non-irrigation water and water-borne pests 2.2.1.2 |

Are the mitigation measures described in the pest modules effective? |

| 6 | Irrigation and protection from non-irrigation water and water-borne pests 2.2.1.2 |

Does the facility source irrigation water as described in the Pest Management Plan to support the outcome to ensure that irrigation water will be clean and free from regulated pests? |

1.4 PCP sub-element 3.2 Employees have adequate technical knowledge and understanding of operation(s) or process(es) for which they are responsible and of how they may impact human, animal or plant health, the environment and other regulatory requirements.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | GCP manager and designated staff 2.1.1 |

Have a GCP manager and alternate been appointed with responsibilities under the GCP? Are they aware of all requirements of the GCP? |

| 2 | GCP manager and designated staff 2.1.1 |

Does the GCP manager have the authority and responsibility to develop and implement procedures that meet the requirements of the GCP? |

| 3 | Designated staff 2.1.1 |

Do individuals that are designated to carry out GCP tasks have adequate skills, knowledge, training and authority? |

| 4 | CFIA audit 2.1.6 |

Will the GCP manager be present for the CFIA audit and will the authorized facility cooperate with the auditor and permit the auditor to collect and record information? |

1.5 PCP sub-element 5.1 Conditions of the premises and surroundings do not contribute to contamination, infection or infestation of regulated commodities.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | Minimum requirements for greenhouse structures 2.2.1 |

Does the facility provide a structure where the plants can be produced within, under or sheltered by the structure and does the structure provide modified growing conditions and/or protection from pests and the outdoor environment? |

| 2 | Buffers and protection from unmanaged plants/areas 2.2.1.3 |

Is a pest exclusion barrier present (or alternatively is a 3 meter/10 foot buffer maintained free from weeds and unmanaged plants) around the production and handling areas, as described in the Pest Management Plan? How are production and handling areas maintained free from weeds and unmanaged plants? |

| 3 | Minimum requirements for greenhouse structures 2.2.1 |

Are production, receiving, handling, storing and shipping areas maintained in good condition? |

| 4 | Minimum requirements for greenhouse structures 2.2.1 |

How are deficiencies in design or maintenance promptly identified and rectified? |

| 5 | Protection from soil and soil-borne pests 2.2.1.1 |

How does the facility ensure that plants are not planted or rooted directly in the ground and how does the facility ensure plants are produced in a manner to prevent contamination by soil-borne regulated pests? |

| 6 | Irrigation and Protection from Non-irrigation water and water-borne pests 2.2.1.2 |

How does the facility ensure protection from non-irrigation water sources, which includes unintentional flooding and the accumulation of standing water? |

2. Audit framework for plant brokers

2.1 PCP sub-element 1.1(a) The process is controlled to achieve regulatory compliance.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | Inventory control 2.1.2 |

How does the GCP manager ensure product identity is maintained within the facility? |

| 2 | Control of non- conforming plants 2.1.2.1 |

How does the GCP manager ensure that non-conforming plants are identified, inventoried and handled in a manner that ensures they are not shipped under the GCP, and that they do not contaminate, infest or become mixed with plants grown/shipped under the GCP? |

| 3 | Notifying the NPPO 2.1.5 |

Should there be a pest find of significance or if there is a situation that is considered a critical noncompliance, will the GCP manager stop shipping the affected certified plants until advice is received from the CFIA? The facility has a process where CFIA will be notified when there is a presence or suspected presence of any condition or situation that may be considered a critical noncompliance at the facility or in association with product purchased or sold, or when there are changes in ownership or the GCP manager. |

2.2 PCP sub-element 1.4 Exported commodities meet foreign country import requirements and conditions and Canadian export requirements, where applicable.

| No | GCP Part IV | GCP Compliance Agreement elements |

|---|---|---|

| 1 | GCP certification documents 2.1.3 | Who has been designated to maintain control of Export Certification Labels and interfacility stamps? |