On this page

- Introduction

- Purpose

- Record keeping

- Incoming eggs

- Washing of eggs

- Conveyance of eggs

- Storage of eggs

- Pasteurization of egg products

- Pasteurization systems and flow schematic

- Critical control records

- No cross connections

- Sealing program for critical equipment

- Constant level tank (CLT)

- Booster pump

- Regeneration

- Flow control device (FCD)

- Heating section

- Cooling section

- Holding section

- Flow diversion device (FDD)

- Indicating thermometer (HTST systems only)

- Safety thermal limit recorder (STLR)

- Programmable logic controllers (PLC) and computers

- Pressure differential controllers (PDC)/gauges

- Homogenizer

- Flow promoting devices/pumps

- Appendix I: Schematics

- Appendix II: Test procedures

- Appendix III: Meter based timing system (MBTS)

- Appendix IV: Preventing cross-connections

- References

Introduction

This document provides information on select preventive control practices for licensed operators who are considering ways to mitigate the food safety risks associated with the handling of shell eggs and the manufacture of processed egg products. This information is intended to inform and support the development and implementation of a preventive control plan. Some historically accepted and proven parameters are included, as well as other example control measures. It is not intended as an exhaustive list of measures. Always ensure that the control(s) chosen are tailored to the uniqueness of your business and shown to be effective for your situation.

Purpose

The Canadian Food Inspection Agency (CFIA) developed this document as guidance to help food businesses comply with the requirements of the Safe Food for Canadians Regulations (SFCR).

It's your choice

You may use other guidance that has been developed by provincial governments, industry associations, international partners, or academic. Always ensure that the guidance you choose is relevant for your particular business, product or products, and market requirements.

Record keeping

In a Preventive Control Plan (PCP), it is important to maintain and keep records of activities which demonstrate that the PCP is implemented and working effectively. Records can be in either a hard copy or electronic format. Refer to Record keeping for your preventive control plan for additional information.

Incoming eggs

The incoming eggs received can present a source of contamination. When conducting the hazard analysis, identify all the hazards that they may introduce, that present a risk of contamination to the food you prepare, and implement effective control measures that prevent or reduce these hazards and ensure their suitability for use.

Information on general preventive controls that can be implemented, to ensure the foods/ingredients received are safe and suitable for use, are presented in the guidance Incoming ingredients, materials and non-food chemicals and Supplier Food Safety Assurance Program (SFSAP).

1 type of hazard associated with eggs is Salmonella enterica subspecies enterica servovar Enteritidis (S. Enteritidis). Industry is encouraged to consult Health Canada's Guidance on Reducing the Risk of Salmonella Enteritidis in Shell Eggs Produced in Canada, a consensus-based guidance for reducing the risk of S. Enteritidis contamination in shell eggs during the entire production chain, from the laying flocks to the egg grading facilities. Consideration should be given to the recommendations contained within, including:

- source laying flocks from hatcheries and pullets free of S. Enteritidis

- environmental testing of laying flocks for S. Enteritidis as per the minimum national standard sampling protocol and methodology

- eggs from flocks whose environments are positive for S. Enteritidis should be diverted directly to further processors for the lifetime of that flock

Note that a health risk assessment may be necessary for eggs sold at retail that are from a positive S. Enteritidis flock.

- egg producers supplying shell eggs to the table market should participate in a Hazard Analysis Critical Control Point (HACCP)-based program designed to reduce S. Enteritidis

- imported eggs are to be sourced from suppliers utilizing an equivalent testing scheme for S. Enteritidis

- eggs (domestic or imported) should have effective traceforward and traceback procedures

Under the SFCR, operators are responsible to notify the CFIA of when food presents a risk of injury to human health, and to immediately take action to mitigate the risk.

Consider the following factors in shell eggs received to prepare a processed egg product:

- the amount of dirt

- the number of weak shells

- the extent of leakers in the lot of eggs

Address these factors using control measures, for example:

- setting a dirty egg tolerance for ungraded eggs

- establishing a SFSAP with suppliers to ensure compliance with this tolerance

- checking compliance with this tolerance:

- rejecting or culling eggs that do not comply

- redirecting non-compliant eggs to be handled separately, in a manner that will reduce the risk of contamination to the processed product and ensures they are free of dirt before they are processed such as:

- washing these eggs at the end of the shift, to reduce contamination of the wash water, and in a manner that ensures the dirt is removed

- inspecting the eggs for leaks, mold or odours and rejecting or culling the affected eggs

- monitoring the compliance of incoming graded eggs with their grade

Implementing these control measures, prior to the washing step, helps support the effectiveness of the subsequent steps in addressing hazards.

Washing of eggs

This section is intended to give an overview of how eggs should be washed and to aid in identifying problems.

Pre-washing

Consider the following factors prior to washing eggs:

- the amount of stain

- the amount of dirt

- the number of weak shells

- the extent of leakers in the lot of eggs

Where excessive numbers of any of these kinds of eggs exist, make extra effort to remove them prior to the washing stage. This can be accomplished by placing personnel prior to the washer to remove these types of undesirable eggs. Wash eggs that are in bad condition at the end of the shift to prevent contaminating the wash water.

Washing

Ensure the water used to wash eggs is a minimum of 11°C warmer than the eggs and, in the case of a system that uses recirculated water, the water is maintained:

- at a temperature that is not less than 40°C and

- at a pH level that is not less than 10

In addition, the egg wash water:

- contains a shell egg cleaning compound that is safe and effective

- is changed at the end of each shift, and more frequently as may be necessary to avoid contamination of eggs and

- is maintained at a level that permits a continuous overflow (in the case of a recirculating washing system)

Shell temperature is at 7–13°C (45–55°F). A target pre–rinse temperature of 32–35°C (90–95°F) is used for optimum results. This pre–rinse can have a warming effect on eggs as well as a pre–soaking for eggs with dirt. The warming effect of the pre–rinse stage is important, particularly when cool eggs are received at the washer, such as at 7°C (45°F) or less. The pre–rinse will warm the shell in an effort to eliminate thermal cracks prior to the entrance into the washer. In addition, the soaking effect will facilitate the removal of dirt during the washing process.

Many wash water temperatures have been tried and are used. A target water temperature of 43–46°C (110–115°F) often has little effect on eggs received at 13°C (55°F) and will aid in the effectiveness of the detergents.

The final rinse is used primarily to remove detergent and wash water from the shell and to have a warming effect on the shell in preparation for the blower and the final drying of the eggs. Recommended temperature here is from 49.0–54.4°C (120–130°F).

Caution: it is recommended that the temperature difference between the wash water and the egg be no greater than 28°C (50°F) to minimize the likelihood of causing thermal cracks. However the wash water temperature should always be at least 11°C (20°F) warmer than the shell in order to discourage the entrance of wash water into the pores of the egg.

The air blower

The purpose of the air blower is to aid in the drying of the eggs. For this process, low relative humidity is desirable because a low relative humidity aids in drying the water from the surface of the egg shell. A relative humidity of less than 85% is recommended. The temperature of air from the blower can range from 20–24°C (68–75°F) depending on room temperature or the temperature of outside air. The filter on the intake is kept clean to ensure the effectiveness of the process. Every effort should be made to dry the eggs prior to packing, to minimize bacterial counts on the shells of eggs and to reduce the possible contamination of the eggs during cooling.

Washers

Maintenance of the washers and parts of the washers is very important for the effective and efficient washing of eggs.

- Brushes should be properly adjusted according to the manufacturer's design specifications. When brushes become worn they are replaced. Brushes do not apply an excessive amount of pressure on the eggs.

- Spray effectiveness depends on:

- the working state of the nozzles(they are well maintained and fully functional)

- the ability to have direct spray through the brushes onto the egg where possible

- the effectiveness of the roller in conveying the eggs. It is recommended that a screen be in place to cover the reservoir opening

- The exhaust should be directed to the outside, and be capable of removing all of the steam and moisture coming from the washer. The exhaust can become very dirty and a possible source of contamination. There should be an inspection port on the exhaust so that the cleanliness of the exhaust can be verified and that there is no condensation dripping back onto the eggs.

- Effective results have been achieved by maintaining a continuous change of water. This can be achieved by allowing a significant amount of water to continually drain from the machine while new water is being added.

Some of the beneficial changes made to conventional washers include:

- An input of water at the bottom of the reservoir. The purpose of this is to have a better cleaning effect during the clean–up period. The water is flushed along the bottom of the tank, aiding in the removal of particles settling there.

- Varying degrees of continuous draining and overflows have been tried. This continuous draining and overflow is beneficial only if frequent changes to the wash water have occurred, that is approximately every 2 hours.

- In the case of those reservoirs which contain heating coils, these coils should be raised for cleaning purposes. Note: a system that has been tried to clean the coils is to turn them on for a brief period of time when the reservoir is empty. This should be monitored carefully, and the coils left on just long enough to cook off the adhering material.

Organic and inorganic (including hard water) materials cause dirty wash water. These materials bind detergents and inhibit their activities. Organic and inorganic compounds act as elements for the growth of bacteria. Hard water in itself can cause excessive scaling on the equipment. Many egg facilities have switched to soft water to reduce scaling/foaming effect in the water. As the pH increases to 11 to 12.5, there is a bactericidal effect on gram–positive bacteria. In addition, a higher pH for a short period of time may be used in wash water having high bacterial counts. Primarily 2 kinds of detergents are used in the egg industry: the chlorine base and the non–chlorine base. Either can be effective if used under proper conditions.

The metering of detergents into the wash water has many advantages. Most importantly, it supplies a constant level of detergent in the water for the cleansing action on the eggs. It also tends to maintain a constant pH level in the water, particularly when trying to maintain high pH levels to prevent bacterial growth.

Intermittent use is a procedure where detergents are added in batch amounts as recommended by the manufacture at various intervals of the washing cycle. The disadvantage of the approach is converse to the metering approach in that there is a tendency to have uneven levels of detergent in the wash water, resulting in fluctuating pH levels.

Effectiveness of the maintenance of the wash water can be demonstrated through a sampling program which monitors the bacterial load.

Final rinse

Final rinses are primarily used to wash the detergent from the egg and raise the temperature of the shell to facilitate drying. For the most part, plain water rinses are used. There is conflicting evidence on the use of sanitizers in these rinses. 1 of the strong advantages of using a chlorine sanitizer from a microbiological point of view is the residual effect of the sanitizer on the equipment surfaces which come in contact with the egg. The final rinse may be diverted to the reservoir to add to the incoming fresh water into the reservoir.

Prior to breaking, eggs should be spray-rinsed with a sanitizing agent.

Clean-up of the washer

During the day's operation, if the tank is drained, it should be sprayed during the draining process with a high–pressure water spray to remove particles from the inside of the washer. The screens covering the reservoir should be cleaned and scraped every 2 hours or more often if required.

At the end of the day, the tank should be drained completely, and the lid left open. Using appropriate water pressure, thoroughly spray the inside of the washer and reservoir tank.

Ensure that the brushes are sprayed clean, as this is 1 of the more troublesome areas for product and bacteria build–up. Scrape the screens thoroughly. Use scrub brushes on those areas that have not been properly cleaned. The use of detergent is recommended. Detergent use may become optional where good cleaning schedules have been maintained. When detergents are used in conjunction with the pressure spray, a rinse is required to remove the detergent from the walls of the washer. Drain the washer, and leave the lids open to ensure that they are dry. Drying of all areas of the washer is 1 of the important factors in maintaining low bacterial counts.

Clean–up (acid bath)

Fill the tank with water at a target temperature of 43–66°C (110–150°F). Add the acid cleaner as per the manufacturer's recommendations. Circulate the water through the washer as required. Drain the acid solution. Rinse the tank with the high–pressure water spray and let dry. The use of warm water in conjunction with this wash will aid the effects of the acid as well as facilitate faster drying after the rinse.

Post-wash handling of equipment and the eggs

All equipment, including the conveyors, washer, dryer, candling booth, scales and packer are kept clean and in good repair, following the manufacturer's recommendations. The glass protector over the candlers is kept clean to prohibit any bacteria build–up in this heated area. A screening filter is used to prohibit the entry of heavy dust or dirt particles into the blower. Towels used for keeping conveyor belts clean are washable or disposable, and should be changed as required.

Conveyance of eggs

All conveyor systems such as carts, trolleys and boxes/cases should not pose a risk to food safety. Plastic trays for ungraded eggs should be cleaned, sanitized and dry before being returned to an egg producer.

Reuse of packaging is not to pose a risk to food safety and is in compliance with the SFCR.

Handling of incompatible products

Ensure that any graded eggs returned to a licensed egg facility from trade are only conveyed as edible eggs when destined for another licensed processed egg facility (for further processing).

Storage of eggs

Have adequate designated areas for the storage of graded eggs.

Maintain the temperature of any room where eggs are held in a licensed egg facility at a maximum temperature of:

(a) 10°C in the case of a room holding eggs graded Canada A, Canada B or Canada C

(b) 13°C in the case of a room holding eggs graded Canada Nest Run, ungraded eggs or eggs bearing a dye-mark

Maintain the relative humidity of any room where eggs are held in a licensed egg facility at a maximum of 85%.

Pasteurization of egg products

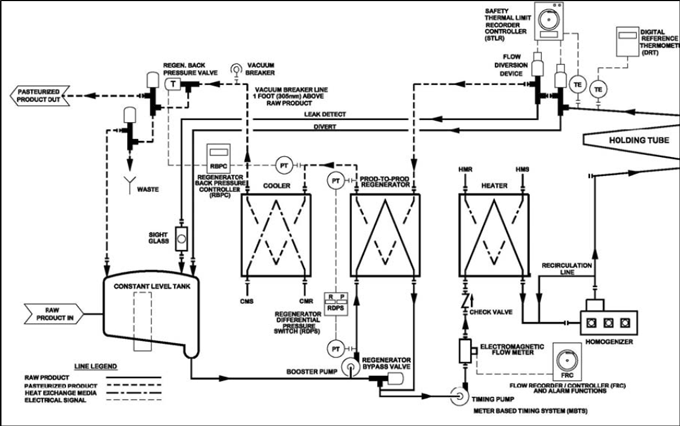

Pasteurization systems and flow schematic

Liquid egg pasteurization may be achieved by using conventional High Temperature Short Time (HTST) pasteurizers or Extended Shelf Life (ESL) pasteurization systems.

Divert flow conditions during processed egg pasteurization may be caused by various factors such as temperature, pressure or flow. Unlike dairy processing, during shutdown or divert modes, the delicate nature of liquid egg to high temperature may cause the liquid egg in the heat exchanger to coagulate and block the system. Thus, in most cases, the system cannot resume forward flow conditions after a shutdown or divert unless it undergoes a sanitization cycle.

In some situations, an instantaneous diversion may occur, resulting in the forward flow valve to return to forward flow within 1 to 2 seconds. This type of diversion is sometimes associated with a brief interruption or fluctuation in the power supply.

Maintain a flow schematic diagram outlining the pasteurization system and keep it up to date. All components of the pasteurizer system (for example, pumps, valves, thermometers, vacuum breaks (optional), recirculation lines, divert lines, leak detect lines, pressure gauges/sensors) should be on the flow schematic diagram. When equipment and/or pipelines are installed or changed, the licence holder ensures that the flow schematic is updated. In situations where automated systems are used, modifications or additions to pipeline configurations and installation of automated valves may be required. Even slight modifications made to the pasteurization system or Clean in Place (CIP) system may have an impact on its processing operation and its safety. A typical HTST system with its components is illustrated in Figure 1 Appendix I.

Extended Shelf Life (ESL) Systems for Liquid Egg Processing

These systems, although designed to operate like an Ultra-High Temperature (UHT) system at higher temperature and pressure, cannot be used as such in liquid egg processing due to the nature of the product. These systems can, generally, be distinguished from conventional HTSTs by 4 main factors:

- location of the flow diversion device in the system

- pre-op conditions for system sterilization

- divert and shutdown conditions

- method of heating: tube-in-tube/tubular heat exchangers

Critical control records

The term pasteurization with respect to processed egg means that every particle of the liquid egg has been heated at a temperature and for a time sufficient to destroy all pathogenic types of microorganisms present.

The pasteurization records contain all the required processing information and indicate if the products have been adequately pasteurized. All recording charts for all products should be available for review.

Established temperature and time requirements

Temperature and time are critical factors required to achieve pasteurization. Failure to achieve pasteurization may result in microbiological hazard in the processed egg product. For a list of established time and temperature, refer to the tables below.

| Item | Liquid processed egg | Minimum temperature of the processed egg at the automatic diversion valve (°C) | Minimum temperature of the processed egg at the automatic diversion valve (°F) | Minimum heating time (minutes) |

|---|---|---|---|---|

| 1 | Egg white (albumen) (without chemical additives) | 54 | 130 | 3.5 |

| 2 | Whole egg with less than 24% egg solids | 60 | 140 | 3.5 |

| 3a | Whole egg with no less than 24% and no more than 38% egg solids | 61 | 142 | 3.5 |

| 3b | Whole egg with no less than 24% and no more than 38% egg solids | 60 | 140 | 6.2 |

| 4a | Whole egg mix with less than 2% added salt or sweetening agent, or both | 61 | 142 | 3.5 |

| 4b | Whole egg mix with less than 2% added salt or sweetening agent, or both | 60 | 140 | 6.2 |

| 5a | Whole egg mix with no less than 2% and no more than 12% added sweetening agent | 61 | 142 | 3.5 |

| 5b | Whole egg mix with no less than 2% and no more than 12% added sweetening agent | 60 | 140 | 6.2 |

| 6a | Whole egg mix with no less than 2% and no more than 12% added salt | 63 | 146 | 3.5 |

| 6b | Whole egg mix with no less than 2% and no more than 12% added salt | 62 | 144 | 6.2 |

| 7a | Yolk | 61 | 142 | 3.5 |

| 7b | Yolk | 60 | 140 | 6.2 |

| 8a | Yolk mix with less than 2% added salt or sweetening agent, or both | 61 | 142 | 3.5 |

| 8b | Yolk mix with less than 2% added salt or sweetening agent, or both | 60 | 140 | 6.2 |

| 9a | Yolk mix with no less than 2% and no more than 12% added sweetening agent | 63 | 146 | 3.5 |

| 9b | Yolk mix with no less than 2% and no more than 12% added sweetening agent | 62 | 144 | 6.2 |

| 10a | Yolk mix with no less than 2% and no more than 12% added salt | 63 | 146 | 3.5 |

| 10b | Yolk mix with no less than 2% and no more than 12% added salt | 62 | 144 | 6.2 |

| 11a | Ova | 63 | 146 | 3.5 |

| 11b | Ova | 62 | 144 | 6.2 |

| 12a | Egg product with less than 24% total solids | 61 | 142 | 3.5 |

| 12b | Egg product with less than 24% total solids | 60 | 140 | 6.2 |

| 13a | Egg product with no less than 24% and no more than 38% total solids Table Note a | 62 | 144 | 3.5 |

| 13b | Egg product with no less than 24% and no more than 38% total solids Table Note a | 61 | 142 | 6.2 |

| 14a | Egg product with more than 38% total solids | 63 | 146 | 3.5 |

| 14b | Egg product with more than 38% total solids | 62 | 144 | 6.2 |

Table Note

- Table Note a

-

Regardless of the total solids content, egg product must be heated to 63°C (146°F) for 3.5 minutes or to 62°C (144°F) for 6.2 minutes if there is no less than 2% and no more than 12% added sweetening agent or salt, or both.

| Item | Dried egg white (albumen) | Minimum temperature of the processed egg in the heat-treating room (°C) | Minimum temperature of the processed egg in the heat-treating room (°F) | Minimum heating time (days) |

|---|---|---|---|---|

| 1 | Spray-dried egg white (albumen) | 54 | 130 | 7 |

| 2 | Pan-dried egg white (albumen) | 52 | 125 | 5 |

| Item | Liquid processed egg | Time held in facility (hours) | Maximum temperature (°C) | Maximum temperature (°F) |

|---|---|---|---|---|

| 1a | Egg white (albumen) (without chemical additives): | |||

| 1b | (a) not to be stabilized | Less than 8 | 13 | 55 |

| 1c | (a) not to be stabilized | 8 or more | 7 | 45 |

| 1d | (b) to be stabilized | Less than 8 | 21 | 70 |

| 1e | (b) to be stabilized | 8 or more | 13 | 55 |

| 2a | Whole egg and yolk, and whole egg mix, yolk mix and egg product with no more than 12% added sweetening agent | Less than 8 | 7 | 45 |

| 2b | Whole egg and yolk, and whole egg mix, yolk mix and egg product with no more than 12% added sweetening agent | 8 or more | 4 | 40 |

| 3a | Egg product with more than 12% added sweetening agent | Less than 8 | 7 | 45 |

| 3b | Egg product with more than 12% added sweetening agent | 8 or more | 4 | 40 |

| 4a | Whole egg mix, yolk mix and egg product, with no more than 10% added salt | Less than 8 | 7 | 45 |

| 4b | Whole egg mix, yolk mix and egg product, with no more than 10% added salt | 8 or more | 4 | 40 |

| 5a | Whole egg mix, yolk mix and egg product, with more than 10% added salt | Less than 30 | 18 | 65 |

| 5b | Whole egg mix, yolk mix and egg product, with more than 10% added salt | 30 or more | 7 | 45 |

| 6 | Ova | N/A | N/A | N/A |

The times listed in the above table are the minimum times (not average times) required to achieve the result of an effective pasteurization.

Other time and temperature processes may be acceptable if appropriate validation and controls are completed and implemented by the licence holder.

| Item | Liquid processed egg | Time held in facility (hours) | Maximum temperature (°C) | Maximum temperature (°F) |

|---|---|---|---|---|

| 1a | Egg white (albumen) (without chemical additives): | |||

| 1b | (a) not to be stabilized | N/A | 7 | 45 |

| 1c | (b) to be stabilized | N/A | 13 | 55 |

| 2a | Whole egg and yolk, and whole egg mix, yolk mix and egg product with no more than 12% added sweetening agent | Less than 8 | 7 | 45 |

| 2b | Whole egg and yolk, and whole egg mix, yolk mix and egg product with no more than 12% added sweetening agent | 8 or more | 4 | 40 |

| 3a | Egg product with more than 12% added sweetening agent | Less than 8 | 7 | 45 |

| 3b | Egg product with more than 12% added sweetening agent | 8 or more | 4 | 40 |

| 4a | Whole egg mix, yolk mix and egg product, with no more than 10% added salt | Less than 8 | 7 | 45 |

| 4b | Whole egg mix, yolk mix and egg product, with no more than 10% added salt | 8 or more | 4 | 40 |

| 5a | Whole egg mix, yolk mix and egg product, with more than 10% added salt | Less than 24 | 18 | 65 |

| 5b | Whole egg mix, yolk mix and egg product, with more than 10% added salt | 24 or more | 7 | 45 |

| 6 | Ova | N/A | 4 | 40 |

Process control records

Process control records are a part of a preventive control plan. This information is recorded to provide a permanent record. Since this information provides a processing record, it will assist the licence holder in tracking down quality and safety problems and prevent recalls of their products. As these records are the only historical record of exact happenings of the pasteurization of each product, it is very important that they adequately and accurately reflect the heating process. The process control record(s) is the record of the pasteurization process. The process control record(s) is reviewed at an appropriate frequency by a responsible person designated by the licence holder.

Process control records for HTST pasteurizers provide the following data:

- licence holder's name and address or licence number

- date, shift and batch number where applicable

- safety thermal limit recorder (STLR) identification when more than 1 is used

- product type and amount of product processed (may be recorded in production records)

- identification of CIP cleaning cycles, mini-wash cycles (if used)

- corresponding indicator thermometer reading during processing. This reading must never be lower than the recording thermometer reading. The indicating thermometer is the reference thermometer and the recording thermometer represents the record of the pasteurization process.

- a record of the product cut-in (the temperature at which the divert valve of the flow diversion device starts to move to forward flow position) and cut-out (the temperature at which the flow diversion device moves to divert position) indicating thermometer temperatures at the beginning of the production and when a new divert temperature is selected (applicable to HTST systems only). The cut-in/cut-out must be performed under any 1 of the following circumstances:

- upon start-up

- when a new set-point is selected.

- after shut down and re-start

- record of the time during which the flow-diversion device is in the forward flow position. The event pen-arm records this information on the outer edge of the chart

- operators comments and reasons for all unusual occurrences

- signature or initials of operator

- record of the set point where multiple process temperatures are used

In addition, for a pasteurizer system equipped with a meter based timing system (MBTS) as a flow control device (FCD), flow records provide the following information:

- licence holder name and address or licence number

- date

- pasteurizer number

- product processed

- frequency or event pen information (the duration of any alarm situation)

- synchronized flow control chart time with safety thermal limit recorder chart

- signature and initials of the operator

- record of any unusual occurrences

Note: some safety thermal limit recorders have the capability of recording both the temperature and flow of the process. These are acceptable if there is no evidence of overlapping of traces on the processing records and there are separate event pens for each recording.

Retention of process control records

All pertinent processing records should be retained as part of a preventive control plan. These records will assist the licence holder and regulatory agencies to determine if the products were adequately pasteurized. Target time-frames for retention:

- a 1 year period minimum and/or

- until the finished product has been consumed (if more than 1 year)

No cross connections

A cross-connection is a direct connection of piping allowing 1 material to contaminate another. There needs to be a complete segregation of incompatible products such as raw materials and pasteurized food products; cleaning products and food products (including potable water); and waste materials or utility materials and food products. Consideration also needs to be given to preventing inadvertent cross contamination of food products which may pose allergenic concerns. Established guidance on the segregation between raw and pasteurized products can be found in Appendix IV.

For other applications (CIP supply lines and return line circuits used for CIP cleaning and mini-washes on tanks, lines, pasteurizers or other equipment that may be washed while connected to product lines containing liquid egg or potable water and lines for final rinse), this segregation is accomplished by the use of separate pipelines and vessels for incompatible products and establishing effective physical breaks at connection points by at least 1 of the following arrangements: physical disconnecting of pipelines, double block and bleed valve arrangements, double seat (mix proof) valves, or other equally effective systems. Refer to Appendix IV for assessment of these applications.

The design of the constant level tank and inlet piping and the flow diversion device area and product piping are areas where potential cross-connections could exist if the design or installation is improper.

Ensure that equipment and/or pipelines are not installed in a manner that will compromise the integrity of the pasteurization or CIP systems, resulting in cross-connections or pasteurization problems. Thoroughly review and approve all proposed installations. Minor changes such as pumps or pipelines are also reviewed and approved. Colour code the pipelines to distinguish between finished product, raw product, CIP lines and other utilities. This will help in the identification of product flow and cross-connections.

Sealing program for critical equipment

There are critical processes that require a particular device to be sealed to ascertain proper control of its critical functions and the safety of the product. Have a program in place to monitor and control the use and replacement of these seals. Records are kept for the sealing of equipment, which identifies (for example sequential numbering system) and lists the seals used and their location, when the seals are broken, reason why the seal was broken, that the equipment was re-sealed and the person responsible who performed this task. To be able to identify which seal has been removed, replaced and recorded, the seals themselves need to be coded.

Constant level tank (CLT)

The constant level tank (CLT) is a reservoir for supply, at atmospheric pressure, of raw or re-circulated product to the pasteurizer to permit continuous operation of the pasteurization system. The constant level tank is located at the start of the pasteurization system. The constant level tank controls the liquid egg level and provides a uniform head pressure to the product leaving the tank.

General conditions

The tank and all components are constructed of stainless steel and are in good mechanical and sanitary condition.

Design

The tank is of such design and capacity that air will not be drawn in the pasteurizer with the product when operating at the maximum capacity of the flow control device. Air in the pasteurizer may allow the liquid egg particles to move more rapidly through the system. Figures 2a and 2b of Appendix I illustrate some possible constant level tank designs. The constant level tank is fabricated so that the raw product will drain to the outlet before the outlet becomes uncovered. 1 method of achieving this is to have the bottom of the tank pitched to the outlet at a minimum downward slope of at least 2 % (0.2 cm per 10 cm) and the top of the outlet pipe lower than the lowest point in the tank (see figures 2a and 2b, Appendix I).

Cover

The tank is fitted with a removable cover or inspection port with a removable cover of suitable design to maintain atmospheric pressure and to minimize the risk of contamination. The cover is pitched to an outside edge to provide drainage. All openings in the cover are flanged upwards and covered. Pipelines entering through the cover (excluding directly clamped lines) are fitted with a sanitary umbrella deflector that overlaps the edges of the opening and is located as close to the tank cover as practical. The cover is used during processing.

Overflow point/diameter

A satisfactory overflow point is the rim of the tank (if not tight fitting with cover) or the top of an overflow outlet below the rim (refer to Figures 2a and 2b of Appendix I).

The overflow outlet below the rim, if present, has a diameter of at least twice the diameter of the largest raw product inlet pipe connected to the constant level tank to enable adequate discharge to drain/floor of product discharged from the inlet pipe while respecting the minimum air gap needed to prevent backsiphonage.

Airspace

The leak detect, divert, CIP line/spray ball, water and liquid egg recycle lines are designed to prevent backsiphonage of raw liquid egg or cleaning products into pasteurized liquid egg or water lines. This is accomplished by ensuring that the lines terminate and break to atmosphere at least 2 times the diameter of the largest return line above the maximum overflow point of the constant level tank. For example, if the largest return line to constant level tank is 3 inches, then this airspace must be at least 6 inches measured from the top of the flood level rim of the overflow pipe to the bottom of the largest return line (see Figure 2b in Appendix I).

Level control device

This device controls the flow of liquid egg to the constant level tank and therefore provides constant head pressure to the product leaving the tank.

The constant level tank is equipped with an automatic device of sanitary design and construction to control the raw product level.

Booster pump

A raw product booster pump may be installed in a conventional HTST pasteurization system under specific conditions. The booster pump is utilized to supplement the flow control device in moving raw liquid egg from the constant level tank through the regeneration section. It may be used to remove excessive vacuum, and subsequent flashing or vaporization, in the regeneration section (particularly when the constant level tank is located an unusual distance from the timing pump).

General conditions

A booster pump is generally a centrifugal pump (see Figure 4 in Appendix I) of sanitary design. The pump must be clean and in good mechanical condition.

The raw product side of the regeneration section may be by-passed when the booster pump is not in operation for example during start-up of the system. This by-pass permits the cold product to be drawn directly to the flow control device from the constant level tank. When the required conditions (for example flow control device operating, flow diversion device in forward flow and product pressure in the pasteurized regeneration section) are met, the booster pump will start to operate, feeding raw product to the regeneration section.

The by-pass line, which may be manually or automatically controlled by a valve, is not normally used when the booster pump is in operation. Prevent entrapment of the product in the by-pass line during periods when the booster pump is in operation by:

- close-coupled by-pass connections (for example, as close as possible; approximately 2.5 times the pipe diameter)

- design of the manually or automatically controlled valve which will permit a slight movement of product through the by-pass line or

- other equally effective system

Location

When a booster pump is incorporated into the HTST system, it is generally located between the constant level tank and the inlet to the raw product side of the regeneration section.

Inter-wiring

A) HTST pasteurizers

A booster pump is only to be used in conjunction with a pressure differential controller and is inter-wired in such a way that it can only operate when:

- the flow control device is operating

- there is proper pressure differential in the regeneration section, for example, pasteurized product pressure in the regeneration section exceeds the raw product side by at least 2 psi (14 kPa)

- the flow diversion device is in the forward flow position

B) ESL pasteurizers

In these systems, the feed pump used to direct the product from the constant level tank to the regeneration section of the heat exchanger is allowed to operate when the flow diversion device is not in the forward flow position since, during divert conditions, the system is programmed to flush all the product out of the system completely and initiate cleaning and sterilization cycles prior to resuming production.

Regeneration

The regeneration section is the section of the pasteurization system where the cold raw product is warmed by hot pasteurized product flowing in a counter current direction on the opposite sides of thin stainless steel plates. The pasteurized product will in turn, be partially cooled.

The regeneration section should:

- have a free draining capability (for example, draining back to the constant level tank by the force of gravity)

- be installed and operated in such a way that the proper pressure relationship exists between the raw and pasteurized product in all the modes of operation, for example forward flow, diverted flow and shutdown

- have no cracks or pinholes

General conditions

Since the physical distance between the various liquids in the pasteurization plates is extremely small, the liquids have the potential to move through the plates and cross-contaminate the product if pin holes exist.

The plates are of sanitary design, constructed of stainless steel or other corrosion resistant material, and are without pin holes. The plates are clean with no presence of liquid egg remnants or foreign materials. The plate gaskets are equipped with leakage grooves, in good condition and not compressed or otherwise showing signs of wear. During operation the pasteurizer does not leak at the plate gaskets.

A routine program to monitor the condition of plates (for example, pin holes in plates, gasket condition, cracks) is established, taking into consideration the design specifications, operating conditions and hours of operation, type of product being pasteurized (for example, salted products), wear and tear and the history of the plates and gaskets. The integrity of all food contact heat exchange surfaces is checked at least twice per year by an acceptable method (for example, dye recirculation, dye check, pressure retention, helium testing). This may be reduced to once per year if salted products are not pasteurized (as per Test 17), and not exported to the USA. However, if there are problems with heat exchanger integrity (plate or gasket issues), a more frequent inspection program is implemented to verify that the problem has been remedied. Appropriate records are kept to show proper testing has occurred. These records should also document the cause of any failure (for example, age, compression, metal fatigue).

Shut-down capability

The unit is designed with the raw product inlet to the regeneration section at the lowest point of the raw regeneration section. Second regeneration sections of a dual regeneration system may have inlet at the top or bottom. The outlet could also be at the lowest point as long as it is free draining to the balance tank.

Pressure differentials

Systems without a booster pump have an appropriate system layout (for example in systems where liquid egg is drawn through the raw regeneration section by the positive displacement pump and pushed under pressure through the remainder of the system) to assure the proper pressure differential. The equipment used to monitor and control will be further discussed below under Pressure differential controllers (PCD)/gauges.

Raw liquid egg and pasteurized liquid egg are separated in the regeneration section only by thin metal plates and a system of gaskets. The raw side of the regeneration section must, at all times, be under lower pressure (at least 2psi (14 kPa) during forward flow) than the pasteurized liquid egg. In the event of metal or gasket leakage, pasteurized liquid egg will leak into raw liquid egg passages, and not vice-versa. The maintenance of this pressure relationship must be safeguarded during periods of start-up operation and shutdown. Failure to maintain the required pressure differential in any section of the regeneration section shall cause all flow promoting devices upstream of any raw regeneration section to be de-energized or isolated from the system, for example booster pump stops in HTST system

In liquid egg-to-heat transfer medium-to-liquid egg type regeneration sections, the pasteurized liquid egg section must be under greater pressure by at least 2 psi (14 kPa) than the heat transfer medium at all times. The protection is on the pasteurized liquid egg side of the system and is engineered to allow pasteurized product to leak into the heat transfer medium in case of regeneration section plate (or tubular) failures. In this type of system, the heat transfer medium (for example, hot water) must be from a safe source. The location of the pressure sensors for these controls is

- at the heat transfer medium inlet on the pasteurized side of the regeneration section and

- at the pasteurized product outlet of the regeneration section

Failure to maintain the required pressure differential in the pasteurized liquid egg section of the regeneration section shall cause all flow promoting devices upstream of any raw regeneration section to be de-energized or isolated from the system and vented to the atmosphere.

Note: in an ESL system, the flow diversion device shall move to the diverted position when the proper pressure differential is not maintained.

Flow control device (FCD)

A flow control device (FCD) controls the uniform rate of flow through the holding tube so that every particle of product is held for the legal minimum period of time. This device is a positive displacement type pump (may be a homogenizer, see Figure 6 Appendix I). Other equally effective mechanisms such as a meter based timing system with proper components (pump or flow control valve, relays, alarms and flow recorder) may also be used as a flow control device. Refer to Appendix III for more information on meter based timing systems.

General conditions

The flow control device is constructed of stainless steel and is in good mechanical and sanitary condition. There is no back-flow through the flow control device in the event of a system shut-down. The driving mechanism is designed so that in the case of, for example, wear, belt stretch, the capacity will not increase. The flow control device cannot be excluded from the system during operation of the pasteurizer. The device is located upstream from the holding tube and normally it is located between the outlet of the raw regeneration section and the inlet of the heater section of the pasteurizer.

The flow control device is an essential component of the pasteurizer, and every effort should be made to maintain its proper operation from both an efficiency and food safety standpoint.

Set and sealed

The maximum operating capacity of the flow control device is designed to ensure an adequate holding time in accordance with acceptable processing requirements.

When homogenizers are located within the pasteurizer set up, timing evaluations are made with these pieces of equipment operating (with no valve pressure on the homogenizer) and by-passed to determine the fastest flow rate (minimum holding time).

Any change in the line resistance of the system after maximum speed of the pump has been set will alter the holding time. Increasing the line resistance by the additions of plates or piping will increase the holding time. This increase in flow resistance in effect reduces the efficiency of the pasteurizer. Decreasing the line resistance by the removal of plates, pipes, or auxiliary units will decrease the holding time. Wear of the drive belts and pump impellers due to normal operation will gradually decrease the rate of flow through the system, thereby increasing the holding time.

The holding time is to be evaluated and re-sealed (if necessary) upon installation and annually thereafter, and in addition, under any 1 of the following conditions:

- whenever the seal on speed setting is broken or

- any alteration is made affecting the holding time, the velocity of the flow (such as replacement of pump, motor, belt, driver or driven pulleys, or addition or removal in the number of heat exchanger plates, pipes or auxiliary units) or the capacity of the holding tube or

- whenever a check of the capacity indicates a speed up

If the licence holder's records indicate that the belts on the timing pump were in new condition when the original holding time was evaluated, then it would not be necessary to re-evaluate the holding time when the belts are being replaced as part of regular maintenance. Keep records of alteration and re-evaluation of the system.

If maximum speed achieves an adequate holding time, a seal is not required. However, a seal is required if either of these conditions exists within a HTST system:

- if the flow control device is a positive displacement pump of the variable speed type which is not controlled by a magnetic flow meter based timing system, it should be sealed at an established capacity (speed setting) that gives legal holding time

- if the system is a meter based timing system, then means should be provided to seal the controls for the high-flow alarm, low-flow and loss-of-signal alarms

Fail safe (operation) capability

All flow control devices are inter-wired with the flow diversion device and safety thermal limit recorder micro-switches. This fail-safe wiring ensures that the flow control device only operates when the flow diversion device is in the safe forward flow or fully diverted mode. Safe forward flow is a condition where the temperature of the product is above the divert set point, and the flow control device is energized by the safety thermal limit recorder or the legal Programmable Logic Controllers (PLC). Fully diverted refers to the flow diversion device valve(s) being properly seated in the divert position so that the microswitch(es) will then energize the flow control device. In the case of a dual stem flow diversion device, this applies to both the leak detect and the divert valves.

All other flow promoting devices in the system (for example, booster pump, stuffing pump) are inter-wired with the flow control device. In the event that the flow control device is de-energized, all flow promoting devices in the system must be stopped or by-passed.

2 factors would prevent the flow control device from operating:

- malfunction or improper assembly of flow diversion device

- "Inspect" mode selected on flow diversion device panel

If the positive displacement pump is equipped with a by-pass line, it should not be used during processing.

If the homogenizer is used as the flow control device, there must not be a by-pass (recirculation line) around the homogenizer during processing. A by-pass may be present for CIP purposes but dismantled and removed during processing. To ensure that no by-pass is present during processing a proximity switch should be utilized so that the flow diversion device will not operate in forward flow. A time delay relay may be installed to permit the flow control device (any acceptable type) to continue operating during the normal time it takes for the flow diversion device to move from forward flow to diverted flow. This type of time delay relay is most common when homogenizers are used as flow control device. The time delay should not be more than 1 second. Appendix III describes the requirements for the meter based timing system.

Heating section

The heating section of the HTST pasteurizer provides rapid, uniform and controlled heating of the product up to pasteurization temperature. The raw product is usually forced through this section by the flow control device.

General conditions

The heating plates are of sanitary design, constructed of stainless steel or other corrosion resistant material and are without any pin holes in the plates.

A routine program to monitor the condition of plates (for example, pin holes in plates, gasket condition, cracks) should be established by licence holders, taking into consideration the design specifications, operating conditions and hours of operation, wear and the history of the plates and gaskets. The integrity of all food contact heat exchange surfaces should be checked at least twice per year by an acceptable method (for example, dye recirculation, dye check, pressure retention, helium testing). This may be reduced to once per year if a licence holder does not pasteurize salted products (as per Test 17), and does not export to the USA. However, if licence holder has experienced problems with heat exchanger integrity (plate or gasket issues), a more frequent inspection program should be implemented to verify that the problem has been remedied. Appropriate records should be kept to show proper testing has occurred. These records should also document the cause of any failure (for example, age, compression, metal fatigue).

The surface of the plates on the heating medium side should be free of excessive mineral scale build-up that impedes heating. The medium side and the product side of the heating plates are free of gasket pieces and other foreign debris that might accumulate there.

The gaskets of the heating plates are equipped with leakage grooves, in good condition and should not be compressed or otherwise show signs of wear. During operation the heating section should not leak at the plate gaskets.

Pressure differentials

In the heating section, the system is designed to maintain pressure on the product side of the plates at least 2 psi (14 kPa) higher than on the medium side of the plates during forward flow conditions.

Pressure gauges or sensors are required on heating sections to verify that the system is properly designed to maintain higher pressure on the product side than the medium side of the plates. Gauges or sensors are located at the heating medium inlet to the heating section and product outlet of the heating section upstream of the holding tube.

Heating medium

Steam used as a heating medium is free of harmful substances or extraneous matter. Boiler and water treatment chemicals and other additives used are safe. Options to be considered are available in the Guidance for Food Establishments Concerning Construction Materials and Packaging Materials and Non-Food Chemicals.

Cooling section

The cooling section of the HTST pasteurizer uses chilled water and/or glycol to provide rapid, uniform and controlled cooling of the pre-cooled pasteurized product coming from the pasteurized regenerator section.

General conditions

The cooling plates are of sanitary design, constructed of stainless steel or other corrosion resistant material and must be without any pin holes in the plates.

A routine program to monitor the condition of plates (for example, pin holes in plates, gasket condition, cracks) is established by the licence holder, taking into consideration the design specifications, operating conditions and hours of operation, wear and the history of the plates and gaskets. The integrity of all food contact heat exchange surfaces is checked at least twice per year by an appropriate method (for example, dye recirculation, dye check, pressure retention, helium testing). This may be reduced to once per year if a licence holder does not pasteurize salted products (as per Test 17), and does not export to the USA. However, if the licence holder has experienced problems with heat exchanger integrity (plate or gasket issues), a more frequent inspection program must be implemented to verify that the problem has been remedied. Appropriate records are kept to show proper testing has occurred. These records should also document the cause of any failure (for example, age, compression, metal fatigue).

The surface of the plates on the cooling medium side is free of excessive mineral scale build-up that impedes cooling. The medium side and the product side of the cooling plates are free of gasket pieces and other foreign debris that might accumulate there.

The gaskets of the cooling plates are equipped with leakage grooves, in good condition and must not be compressed or otherwise show signs of wear. During operation the cooling section does not leak at the plate gaskets.

Pressure differentials

In the cooling section, the system is designed to maintain pressure on the pasteurized product side of the plates at least 2 psi (14 kPa) higher than on the cooling medium side of the plates during forward flow. During diverted flow and shutdown conditions, higher pressure is maintained on the pasteurized product side of the plates than on the medium side of the plates. This reduces the possibility of chemical contamination in the event a pinhole leak develops in the plates. The pressure relationships between the pasteurized product and the cooling medium are monitored and recorded daily. Where licence holder does not have an automatic means to correct the pressure relationship as described above, the pressures are monitored and recorded a minimum of twice daily.

An automated mechanism is 1 way to achieve the correct pressure relationship in the cooling section during forward flow, divert and shutdown conditions so that the pressure on the pasteurized product side is greater than the cooling media side. In systems where there is not an automated mechanism the licence holder has a written program which includes the person responsible, what is to be done, how it is to be done, how often it is done (frequency), records to be kept and results of monitoring, verification procedures (both on-site and record review), and actions taken for deviant situations. The program specifies the parameters of acceptability/unacceptability and defines the preventive measures taken to prevent the re-occurrence of deviations. The program includes at a minimum:

- records of the pressures recorded a minimum of twice a day during production, at beginning and end of run

- microbial cooling media checks (for example, psychrotrophs, coliforms) at a frequency of at least once per week

- pH testing of cooling media at a frequency of at least once per week

- visual cooling media check at least once per week

- pinhole testing and plate teardowns at a minimum of once every 6 months

- plate replacement program

In the event that the written program does not adequately address the risks or there is failure to implement or follow the program then the licence holder should install an automated mechanism.

Where there is an automatic mechanism the cooling medium supply is stopped or diverted and the cooling medium side vented to atmosphere in the following cases:

- during forward flow, when the product pressure on the pasteurized product side drops to within 2 psi (14 kPa) of the cooling medium side of the plates

- during diverted flow and shutdown conditions

Cooling medium

Water treatment chemicals and other additives are safe. Options to be considered are available in the Guidance for Food Establishments Concerning Construction Materials and Packaging Materials and Non-Food Chemicals.

Cooling medium (usually sweet water or water-glycol mixture) is checked at least monthly for microorganisms (for example, psychrotrophs, coliforms). Where a facility licence holder does not have an automatic mechanism the cooling media is checked at least once per week.

Records document the safety of any cooling water additives and cooling media products used, as well as the microbial testing results.

Holding section

This is the part of the pasteurizer in which fully heated liquid egg is held for at least the minimum holding time. This section, which consists of a holding tube and sensing chamber, is located between the heating section of the pasteurizer and the inlet of the flow diversion device.

General conditions

The holding tube and all connections is of sanitary design and construction, and is clean and in good mechanical condition.

To attain the minimum holding time it is critical that the design of the holding tube prevents air from being incorporated into the system. Air in the system will allow individual liquid egg particles to move faster through the holding tube, thereby reducing the holding time. In order to avoid the presence of air in the holding tube, the latter is required to have a continuous upward slope (includes elbows) of at least 2% (2 cm per 100 cm) from the lowest point of the holding tube to the flow diversion device. To prevent variance in the slope, the holding tube is permanently fixed by mechanical supports.

No device should bypass the holding tube. If multiple connections to the holding tube are required to obtain different holding times depending on the product being processed, appropriate measures are taken to ensure that the right connection is used. This has to be automatically controlled to avoid human error.

No portion of the holding tube, between the inlet and the sensing chamber, is heated. The extended holding time use for processed egg pasteurization may require the use of insulation material on tubes.

Holding tube is equipped with removable elbows across the length of the holding tube to allow for adequate inspection of the interior of the elbows and tubes.

Holding time provisions holding verification and records

Holding time is to be determined for each product by measuring the product flow rate (volume per unit time) and length and diameter of holding tubes. Holding time requirements are based on the average moving particle.

Holding time is checked for each product at a frequency to ensure continuous compliance. This may require daily checks for each product. Manual verification of the holding time is performed when any of these 3 conditions is present:

- the system's flow rate is determined via the use of a magnetic flow meter but without appropriate public health controls, for example high flow alarm

- the system is a meter-based timing system with public health controls

- the system is positive displacement pump controlled with no magnetic flow meter

Refer to Test 8 and Test 9 (Appendix II) for holding time verification.

Sensing chamber

The sensing chamber is that portion of the holding tube which houses both the indicating thermometer and the safety thermal limit recorder hot liquid egg temperature sensors and is located at the outlet of the holding tube (See Figure 7, Appendix 1). The sensing chamber should maintain a slope of at least 2%. The indicating thermometer sensor and the recorder controller temperature sensor in the sensing chamber is in close proximity to one another (for example, off-set cross or split double ferrule) to ensure that the temperature of the liquid egg surrounding the 2 sensors yields a common result. The distance between the 2 probes should not be more than 30 cm (12 inches). The center line of the safety thermal limit recorder probe is not more than 45 cm (18 inches) from the center line of the divert valve stem.

Flow diversion device (FDD)

The flow diversion device (FDD) is designed for controlling the direction of product flow according to the temperature of the product leaving the holding tube. Most HTST pasteurizers use a dual stem flow diversion device incorporating 2 3-way valves in series. This system utilizes additional fail safe systems (See Figure 9, Appendix I).

The flow diversion device's valve is actuated by an air-operated diaphragm and a positive action spring. A solenoid (an electronically operated valve) energized by the safety thermal limit recorder or the safety flow limit recorder (SFLR) in the case where the system is a meter based timing system, actuates an air valve within the control box which admits air to, and exhausts air from, the diaphragm. When compressed air is admitted to the diaphragm, the spring is depressed, the lower portion of the valve seats itself, the upper portion of the valve is pulled away from its seat, and forward flow results. Any loss of air pressure or electrical power automatically returns the valve to its normal position, which is diverted flow position.

General conditions

The flow diversion device and the return lines are constructed of stainless steel and are clean and in good mechanical condition. Valves, plunger seals and O-rings are also to be clean and in good mechanical condition. This is necessary to ensure the fail-safe divert capability of the flow diversion device. Stem length of the valve should be non-adjustable to insure that proper seating of the valve is not disturbed. If the stem has a threaded attachment, means are used to prevent any misalignment. Air to the flow diversion device is clean and unrestricted.

Dual stem flow diversion device is designed to be CIP.

It is important that the flow diversion device is free of any device or switches that may override the control functions and jeopardize the safety of pasteurized product. In dual stem diversion devices which have external solenoids, the air lines do not have quick release couplings and should be identified.

Divert line

All flow diversion devices should have a pipeline that is free draining from the diversion port back to constant level tank (HTST pasteurizers) or to drain/recovery tank (ESL systems). This divert line is free of any valves which would permit stoppage of the line or excessive back pressure on the flow diversion device.

Leak detect line (HTST systems only)

This requirement is applicable to HTST pasteurizers only. In ESL pasteurizers, during divert conditions the system is programmed to initiate a complete flushing of the product followed by a full cleaning and sterilization cycles before production resumes.

A) Single stem flow diversion device

There are properly functioning leak detector ports or leak escape ports. They permit the escape, to the atmosphere, of product at sub-legal temperature which may have leaked past the first gasket seal on the forward flow portion of the valve. They prevent sub-legal liquid egg from entering the forward flow line. Leakage at this point should warn the operator that the valve O-rings are faulty. These ports should never be obstructed. These ports (poppets) should be visibly open during divert flow or shut down. The O-rings should be routinely changed.

B) Dual stem flow diversion device

Dual stem flow diversion devices have a leak detect line separate from the divert line, that is free draining from the lower port of the leak detect valve back to the constant level tank or other acceptable receptacle. No restrictions are permitted in the leak detect line as this would exert a higher pressure against the seal possibly forcing raw liquid egg out the forward flow port. This line is to be equipped, in the vertical position, with a sight glass, preferably of the 360 degrees type. The sight glass allows for unrestricted visual detection of leakage past the first valve seat. It is clear with no etching or clouding and be free draining. The sight glass should be installed at eye level wherever possible.

Location

For HTST pasteurizers, the flow diversion device is located at the end of the holding tube after the sensing chamber. It is at the highest point of the raw product in the holding tube.

For ESL systems, the flow diversion device is generally located downstream from the cooler section. In these systems, the flow diversion device is automatically prevented from assuming the forward-flow position until all product-contact surfaces between the holding tube and flow diversion device have been held at or above the required pasteurization temperature continuously and simultaneously for at least the required pasteurization time.

The divert line that is the pipeline from the diversion port of the flow diversion device to the drain or recovery tank is self-draining and is free of restrictions or valves unless such restrictions or valves are designed to prevent stoppage of the diversion line. ESL systems having the flow diversion device located downstream from the cooler are inter-wired or computer controlled to thoroughly clean and sterilize the system, including the divert pipeline, before re-starting of production. The divert pipeline of these systems may be connected to a cooling section which is not self-draining to enable sterilization of the system.

End of line valve for flushing raw product after a divert or shutdown condition

This valve is generally located at the end of the line, downstream from the flow diversion device and final cooling, to flush out product from the system and into a recovery tank following either a divert or shutdown condition. Since this valve separates the pasteurized product lines from the raw product being flushed out, it meets the same criteria as the legal flow diversion device described above.

Fail safe divert capability

In the case of sub-legal temperature, loss of electrical power or air supply, the flow diversion device is automatically returned to the divert position. In all cases the valve response time from forward flow to divert flow does not exceed 1 second.

The flow diversion device is inter-wired with the flow control device. The inter-wiring will permit the flow control device and other flow promoters to operate only when the flow diversion device is in the safe forward flow or fully divert position. Safe forward flow is a condition where the temperature of the product is above the divert set point and the flow control device is energized by the safety thermal limit recorder. In the event of the flow diversion device not being in either the safe forward flow or fully divert position, all flow promoting devices in the pasteurization system (for example, downstream from the balance tank to the break to atmosphere) automatically stop or be by-passed.

Time delay relays (HTST systems only)

Dual stem devices have the proper time delay relays. This can be verified by checking records on tests conducted on HTST equipment and its controls. Time delay relay is a unit which defers a function by a set period of time.

- A minimum 1 second time delay relay is required for dual stem flow diversion devices to flush out any product pocketed between the 2 valve seats. In HTST systems where a restrictor is required in the divert line to obtain legal hold time in diverted flow, the time delay relay must be a maximum of 3 seconds. The maximum 3 seconds of delay is not applicable when the timing system is a meter-based timing system;

- A time delay relay is required for the "Inspect" mode control switch. When the switch is moved from the "Product" to "Inspect" position, the flow diversion device must immediately divert and all flow promoters (includes flow control device) must be de-energized or valved out. The flow diversion device must remain in the diverted flow position until all the flow promoting devices have stopped (run down time or are valved out); after which it moves to the forward position but no flow promoting device shall operate. ;

-

A time delay is required for the CIP mode control switch such that all flow promoters (includes flow control device) cannot operate during the CIP operation. When the switch is moved from the "Product" to "CIP" mode, the flow diversion device must immediately divert and all the flow promoters must be de-energized. The flow diversion device remains in diverted position until all flow promoting devices have stopped (run down time). The flow diversion device is then under the control of the CIP controller,

or

- A time delay relay is required when it is desired that the flow promoting devices run during CIP operation. This time delay relay must position the flow diversion device in the diverted flow for at least 1 minute of CIP cycle. Any product pump which may produce pressure on raw regeneration section also shall not run during that minute of the CIP cycle and must be under control of the same time delay relay as the flow diversion device. If mini-washes are done, chemical cross contamination must be prevented through the use of systems outlined in Appendix IV.

If the HTST pasteurizer has a meter based timing system as a flow control device then the following additional control is required:

- the flow diversion device will divert immediately when the flow deviates from set points (above high set point or below low set point)

Device sealed

Sealing this unit will prevent any tampering with control switches and time delay relays. All solenoids, time delay relays and critical micro-switches must be sealed. In some cases, this can be achieved by sealing the control panel box. However, if the components are not in 1 box, it will be necessary to seal each component.

Indicating thermometer (HTST systems only)

The pasteurizing indicating thermometer provides the official processing temperature of the product.

General conditions

This thermometer is required for all HTST pasteurizers. It should be mercury actuated or resistance temperature devices (RTD). (See Figure 10, Appendix I).

Mercury actuated or accepted equivalent thermometers should be of direct reading type, contained in a corrosion resistant case which permits easy observation of column and scale.

The RTDs type must be fail-safe utilizing 2 separate RTDs, accurate, reliable, and meet the scale and thermometric response specifications. The criteria in Appendix II, Addendum – Testing Apparatus Specifications for Digital test thermometers should be used to evaluate RTDs when used as alternatives to mercury actuated direct reading thermometers.

Location/accessibility

The hot product indicating thermometer is located in the temperature sensing chamber along with the probe for the safety thermal limit recorder. If the indicating thermometer is not readily accessible, the operator provides adequate and safe access to it.

Both the probe and the digital readout have means to prevent unauthorized access which can be accomplished by sealing of these devices.

Specifications

The mercury column width is magnified to an apparent width of at least 1.6mm (0.0625 inch). The scale has a span of at least 14°C (25°F) including the pasteurization temperature +/- 3°C (5°F), graduated in 0.25°C (0.5°F) divisions with not more than 4 Celsius degrees (8 Fahrenheit degrees) per 25mm (1 inch) of span. The thermometer is protected against damage at 105°C (220°F). Indicating thermometer is in the same unit of measure as the recording thermometer, either both are Celsius or both are Fahrenheit.

The stem fitting is pressure tight against the inside wall of the fitting with no threads exposed to product. The distance from the product contact surface of the ferrule to the sensing area of the bulb is at least 76 mm (3 inches).

Refer to Appendix II for calibration guidance.

Safety thermal limit recorder (STLR)

The function of this device is to:

- automatically record the temperature of the product in the sensing chamber on a chart that also indicates the time of the day and provides a record of the process

- monitor, control, indicate and record the position of flow diversion device (for example, forward or divert flow)

- supply the source of power for the flow control device and flow diversion device solenoid during forward flow

General conditions

This unit, more commonly referred to as the Recorder Controller, meets the design requirements of the 3-A Accepted Practices for the Sanitary Construction, Installation, Testing, and Operation of High Temperature Short-Time Pasteurizers. Any such units must be manufactured for HTST safety thermal limit recorder usage and any modification is performed by, or authorized by the unit manufacturer.

The safety thermal limit recorder is electrically operated and the unit is housed in a case that is moisture-proof under normal operating conditions (See Figure 11 and 12, Appendix I).

The safety thermal limit recorder is maintained and operated as specified by the manufacturer. Access to public health adjustments is limited to designated qualified individuals. The cut-in/cut-out signal to the flow diversion device is independent of the movement of the temperature recording arm. The single probe which senses the temperature for both the temperature recording pen and the cut-in/cut-out control is protected against temperature damage at 105°C (220°F). It is installed with a pressure tight seat against the inside wall of the pipe with no threads exposed to liquid egg or liquid egg products. The temperature sensing area of the probe is no less than 76 mm (3 inches) from the product contact surface of the ferrule. Flow indicating lights, if present, must be operational (green for forward and red for divert).

All switches on the safety thermal limit recorder and any controls associated with the operation of the HTST unit are clearly identified. There are no switches or devices that could jeopardize the safety of the product by by-passing or overriding any public health controls.

Diversion capabilities

The safety thermal limit recorder have set-points for all the products run. If the unit has only 1 set-point capability, this value is the highest set-point temperature for any product processed on the unit.

Normally dual or multiple temperature set-point devices are installed as needed. Any such device should be supplied or recommended by the manufacturer of the safety thermal limit recorder. When a multiple temperature device is used, the set-point indicator indicates the current set-point in use. A pen attached to the set-point indicator arm, recording the actual set-point is provided.

Cut-in/cut-out (HTST systems only)

The cut-in temperature is that temperature, set within the safety thermal limit recorder, at which the safety thermal limit recorder sends a signal to the flow diversion device allowing it to go into and remain in the forward flow position. The cut-out temperature is the temperature at which this signal is turned off. The adjustment mechanism for this set-point is inaccessible to the operator once the unit has been sealed.

Cut-in and cut-out temperatures are determined and recorded on the chart daily by the operator at the start up and when new set-point is selected. A cut-in and cut-out is required in the following situations:

- when going from 1 mode to another and back again, for example following a mini-wash when on CIP mode

- when there is a new set-point selected for a product

- when the system is shut down and then is re-started

In the case of 1 and 2 this is seen as selecting a new set point and in the case of 3 this is seen as a new start up.

The cut-in temperature is the temperature observed on the indicating thermometer, at the instant the flow diversion device begins to move to the forward flow position. The flow diversion valve responds to the signal sent out by the safety thermal limit recorder when the safety thermal limit recorder senses a product temperature at or above the set-point, and is therefore temperature dependent. For HTST systems equipped with dual stem flow diversion devices, the leak detect valve responds after a pre-set time delay, and is therefore time dependent. The cut-out temperature is the temperature (during descent) at which the flow diversion device assumes the divert flow position. Normally cut-in temperature is higher (at least 0.25°C (0.50°F)) than the cut-out temperature.

With recent technology, it is possible to perform automated cut-in/cut-out temperatures using Programmable Logic Controllers. These systems will be assessed on a case by case basis.

Pens

A) Temperature recording pen

The safety thermal limit recorder has a functioning temperature recording pen. Means should be provided to allow the adjustment on the pen arm enabling the operator to adjust the pen reading to coincide with that of the indicating thermometer.

B) Frequency (event or divert) pen