The risks to food have changed considerably in recent years and continue to change rapidly. At the same time, the Canadian industry has to be more efficient and innovative to compete in a global economy. In this context, the Canadian Food Inspection Agency (CFIA) began to evolve the way it manages risk, supports industry's ability to compete globally, and embraces technology to provide more efficient and responsive service.

The CFIA committed to better use its data, reports and surveillance information to identify trends. This allows the agency to focus on risk and support program design, planning, compliance and enforcement efforts. In support of agency priorities, the CFIA developed an Establishment-based Risk Assessment model for domestic food establishments (ERA-Food) in order to allocate inspection resources based on food safety risks. This risk assessment takes into consideration typical food safety hazards, and is being used to determine the level of oversight required to appropriately manage the risks. The ERA-Food model has been developed by the CFIA in collaboration with experts from academia, industry and other government departments. The development of the model also drew upon the experience of other countries that have used a similar approach to risk assessment, and considered scientific literature and leading edge modelling technology.

The ERA-Food model comprises 3 different groups of risk factors:

- inherent risk factors

- mitigation factors

- compliance factors

Data for the first 2 components are collected through My CFIA, by completing the Additional establishment information (AEI). Regulated parties are prompted to provide the additional establishment information after the SFC license is granted and when the license is amended or renewed, or at any other time. Data on compliance factors are extracted from CFIA databases.

The ERA-Food model risk results provide input into the agency's risk-informed approach to manage food safety risks. This includes the prioritization of inspection activities, oversight strategies and priorities, laboratory capacity mobilization, and work planning. As of April, 2022, the automated calculation and delivery of risk results and risk profiles for the ERA-Food model is implemented in 7 sectors:

- dairy

- maple

- honey

- egg

- processed fruits and vegetables

- fish

- meat

This approach allows for calculating risk results the day after the AEI is completed.

The scientific approach and practical applications to develop the ERA-Food model since 2013 are presented below. Annex 1 presents the Scientific Advisory Committee members and the ERA-Food technical working group.

Scientific approach and practical applications

- Identification of factors associated with food safety risk

- Selection of risk factors for the ERA-Food model

- Risk factors' criteria weighting for the ERA-Food model

- Risk Attribution at the sub-product level

- Design of the ERA-Food model algorithm

- Testing of the model (Pilot projects)

- Performance assessment of the ERA-Food model outputs

- National Data Collection

Identification of factors associated with food safety risk

The objective was to identify the most meaningful food safety risk factors that could potentially be used in a risk assessment model for food establishments. All food hazards were considered. An initial literature review, along with advice from an expert panel, was used to develop a comprehensive list of risk factors that could potentially contribute to the food safety risk attributed to domestic food establishments. In 2013, 75 Canadian experts completed an online questionnaire to assess the 155 identified risk factors according to their impact on food safety. Based on this study, 51 risk factors were excluded. The findings of this expert elicitation are available in Microbial Risk Analysis Journal.

Selection of risk factors for the Establishment-based Risk Assessment model for food establishments

For a quantitative risk assessment model, a limited number of risk factors are needed. Thus, other criteria were considered to select risk factors such as:

- the clarity of their definition

- the merging of risk factors sharing similar concepts

- the inclusion of only measurable risk factors (for example the probability that this factor can be objectively assessed during an inspection process)

- the availability of data sources

The list of risk factors is presented in figure 1 and the process followed for the selection is available in Food Microbiology Journal. Briefly, risk factors are grouped in inherent risk factors, mitigation factors and compliance factors.

Inherent risk factors represent those associated with a specific food commodity, operation or manufacturing process. These factors take into account:

- the type of product

- the distribution volume

- the direct distribution to a vulnerable population, such as residents of nursing homes, hospitals or daycares

Mitigation factors are the measures or strategies that a food establishment is using to reduce the inherent risk and therefore reduce the risk of a food safety issue. Examples of these strategies include:

- the implementation of an internationally recognised private certification scheme (meaning recognised preventive control plan)

- having a full time employee responsible for quality assurance and food safety on site

- the application of specific risk-prevention processes (for example high pressure processing)

Compliance factors refer to a food establishment's track record with respect to how well it has complied with regulatory requirements. This is assessed using the food establishment's historical and current data such as information pertaining to recalls, inspection reports and enforcement actions taken.

Description for image – List of risk factors included in the ERA-Food model

This figure illustrates the list of risk factors included in the ERA-Food model. The first box represents the inherent risk factors which are those associated with a specific food commodity, operation or manufacturing process. Included in this group of risk factors:

- the commodity

- the type of products

- the annual distribution volume

- the type of activities conducted at the establishment

- the direct distribution to vulnerable population

- the processing steps (such as slicing, dicing)

Please note that some factors, namely the commodity, the type of products, the volume and the type of activities are related to the health impact (unit in DALYs – Disability Adjusted life Years) attributed to these risk factors.

The second box represents the mitigation factors which are the measures or strategies that a food establishment has implemented to control the inherent risks and reduce the overall risk of a food safety issue. Mitigation factors include:

- presence of additional processes

- presence of a sampling plan

- food safety certifications

- third party audits

- full time quality assurance personnel

- control of incoming supplies (such as letter of guarantee, audits of suppliers)

The third box represents the compliance factors which refer to a food establishment's track record on how well it has complied with regulatory requirements. Compliance factors are assessed using:

- history of enforcement actions

- recalls (class I, II, III)

- food safety confirmed complaints

- inspector assessment of preventive control plan (PCP) sub-elements

The list under the inspector assessment is the list of preventive control plan (PCP) sub-elements that the ERA model considers under the Integrated Agency Inspection Model (iAIM), that are:

- incoming inputs

- process controls

- import controls

- sanitation, biosecurity and biocontainment

- pest control

- chemicals

- hygiene and biosecurity

- employee training

- equipment design and maintenance

- buildings

- water, ice, steam

- waste disposal

- receiving, transportation and storage

- traceability and control

- complaints

Risk factors' criteria weighting for the Establishment-based Risk Assessment model for food establishments

The objective was to quantify the relative importance of selected criteria used to measure the risk factors included in the ERA-Food model based on their impact on food safety. Overall, 173 criteria were presented to 29 Canadian experts during a 2-round face-to-face expert elicitation to estimate their relative risk to human health. There was a good consensus on the relative risk given to most criteria. Respondent profile did not have an influence on the results. Median values for each criterion are used in the ERA-Food model. The peer-reviewed scientific paper is available in Food Control Journal.

Risk Attribution at the sub-product level

The objective was to estimate the contribution of different food sub-products to foodborne illnesses in the Canadian population. Overall, 64 Canadian experts completed the web-based questionnaire for the 31 selected pathogen-commodity combinations. For each pathogen-commodity combination, experts were also asked to provide their level of certainty. Respondent profiles did not have an influence on the source attribution at the sub-product level for most of the pathogen-commodity combinations. Since experts provided different levels of certainty for each pathogen-commodity combination, a weighted average was used to calculate the source attribution. The peer-reviewed scientific paper is available in International Journal of Food Microbiology.

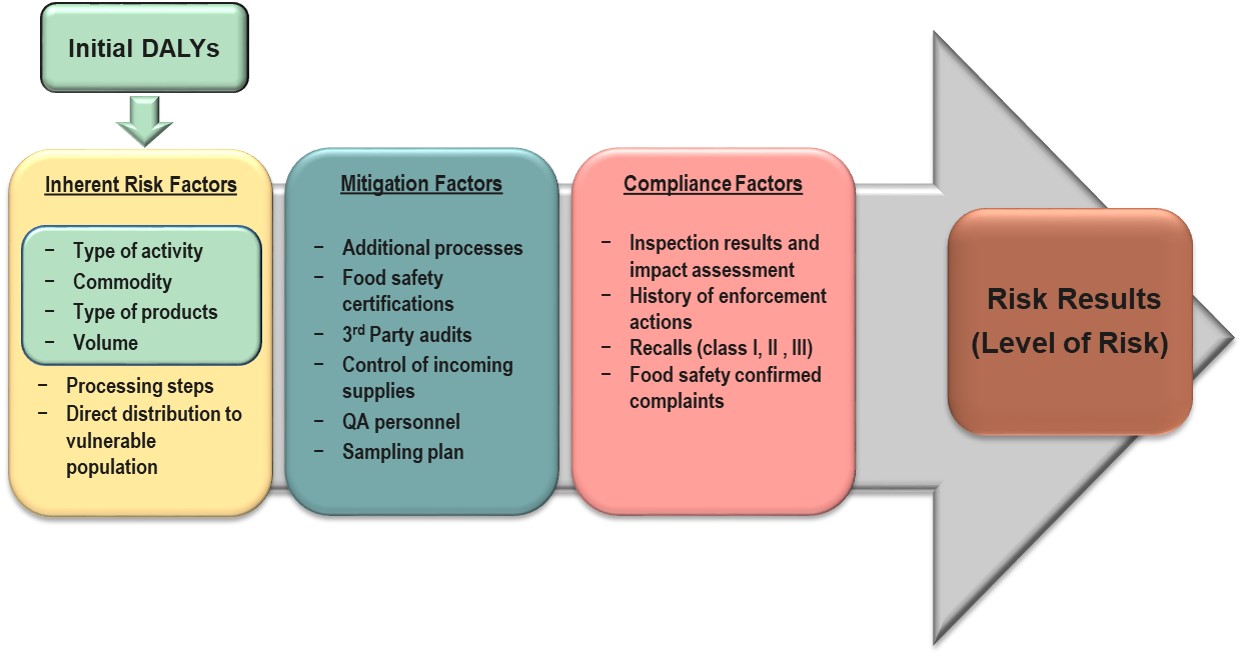

Design of the Establishment-based Risk Assessment model algorithm for food establishments

The ERA-Food model concept is based on the allocation of risks to food establishments based on their impact on consumer health in Canada. The underlying principle is that the total impact (expressed as DALYs) remains constant, but the proportion allocated to individual establishments is fluid. This value takes into consideration the number of cases associated with each food safety hazard yearly, their attribution to specific food commodities and sub-products, and the health impact per case of illness for each hazard. Thus, the health impact is first allocated to individual establishments based on the type of activity and the volume of each product type they manufacture. The establishment-level health impact is then adjusted considering the presence or absence of specific food safety risk factors and their relative risk (figure 2). A scientific paper on the ERA-Food algorithm is currently being prepared for submission to a peer-reviewed journal.

Description for image – ERA-Food model arrow illustration

This figure illustrates the model design as an arrow. First, the initial DALYs are calculated by attributing the health impact to 4 factors: type of activity, commodity, type of products and volume. Then, the health impact is adjusted by the inherent risk factors, the mitigation factors, and the compliance factors represented by the first, second and third boxes, respectively. This then generates the health impact at the establishment level represented by the last box.

Inherent risk factors take into account:

- the processing steps

- the direct distribution to vulnerable population

Mitigation factors include:

- presence of additional processes

- food safety certifications

- third party audits

- control of incoming supplies

- quality assurance personnel

- presence of a sampling plan

Lastly, compliance factors are assessed using:

- inspection results and impact assessment

- history of enforcement actions

- recalls (class I, II, III)

- food safety confirmed complaints

Testing of the model (pilot projects)

The objectives of the commodity-specific pilot projects were to obtain risk results and to validate the data collection tool. Food establishments were randomly selected.

| Commodity | Number of participating establishments out of the total number of establishments randomly selected | Completion date |

|---|---|---|

| Dairy | 29/29 | June 2014 |

| Meat/poultry | 49/52 | June 2014 |

| Fish/seafood | 49/52 | February 2017 |

| Maple | 31/32 | September 2017 |

| Honey | 30/32 | October 2017 |

| Eggs and egg products | 28/32 | April 2018 |

| Fruits and vegetables | 30/46 | September 2019 |

As a result of the pilot project data analysis, as well as feedback from establishments and inspectors, a simplified, improved and automated version of the data collection tool was developed, and is now available through My CFIA, by completing the Additional establishment information.

Performance assessment of the Establishment-based Risk Assessment model outputs for food establishments

The objectives of this step were to estimate the agreement between the risk assessments provided by the ERA-Food model and CFIA senior inspectors, and to refine the model based on the identification of major discrepancies.

For each food establishment that participated to the commodity-specific pilot projects, information related to the risk factors used as inputs in the ERA-Food model was summarized in 1 page. Each expert categorized 10 establishments according to their risk to the health of consumers, including:

- 8 randomly selected food establishments from the commodity-specific pilot projects

- 2 controls (1 with the lowest risk and 1 with the highest risk)

The controls were created by the ERA-Food technical working group.

| Commodity | Number of participating CFIA senior inspectors | Outcome |

|---|---|---|

| Dairy | 22 | A good correlation was achieved between the ERA-Food model and inspectors' assessment. Minor refinements were done in the algorithm. |

| Meat/poultry | 39 | |

| Fish/seafood | 31 | Discrepancies were identified and triggered a reassessment of the categorization of fish sub-products. |

| Maple | 23 | Inspectors did not consider the production volume as significantly impacting the risk result of an establishment. When fixing this variable, the correlations were excellent. Since the volume is used as a measure of exposure assessment by the model, no adjustment will be done to ERA-Food for these commodities. |

| Honey | 21 | |

| Eggs and egg products | 24 | A very good correlation was achieved between the ERA-Food model and inspector assessment. |

| Fruits and vegetables | 17 | A moderate correlation was achieved between the ERA-Food model and inspector assessment. A more precise risk assessment at the fresh fruits and vegetables sub-product level was suggested. |

National Data Collection

The ERA-Food model is being implemented in a commodity by commodity approach through a national data collection phase. In order to collect information for the inherent, mitigation and compliance factors and assess the risk of all federally regulated domestic food establishments, regulated parties are invited to fill out an online questionnaire (Additional establishment information) through My CFIA. The ERA-Food risk results are being used in inspection planning and are providing input into the agency's risk-informed approach to managing food safety risks.

The ERA technical working group is currently adapting the ERA model for food importers (Importer Risk Assessment model). This approach was used to develop:

- the Establishment-based Risk Assessment model for hatcheries (ERA-Hatchery)

- the Establishment-based Risk Assessment for feed mills (ERA-Feed mill)

- the Establishment-based Risk Assessment model for renderers (ERA-Renderer)

For more information, email cfia.eramodel-modeleere.acia@inspection.gc.ca.

Annex 1 – The Scientific Advisory Committee members and technical working group for the Establishment-based Risk Assessment model for food establishments, as of August 2021

| Name | Affiliation |

|---|---|

| Sylvain Quessy | Université de Montréal |

| Julie Arsenault | Université de Montréal |

| Jeffrey Farber | University of Guelph |

| Sylvain Charlebois | Dalhousie University |

| Tom Gill | Dalhousie University |

| Rick Holley | University of Manitoba |

| Aamir Fazil | Public Health Agency of Canada |

| Greg Paoli | Risk Sciences International |

| Martin Duplessis | Health Canada |

| Anna Mackay | Canadian Food Inspection Agency |

| Name | Affiliation |

|---|---|

| Manon Racicot | Canadian Food Inspection Agency |

| Romina Zanabria | Canadian Food Inspection Agency |

| Alexandre Leroux | Canadian Food Inspection Agency |

| Geneviève Comeau | Canadian Food Inspection Agency |

| Raphaël Plante | Canadian Food Inspection Agency |

| Suzanne Savoie | Canadian Food Inspection Agency |

| Virginie Lachapelle | Canadian Food Inspection Agency |

| Elisabeth Mantil | Canadian Food Inspection Agency |

| Tamazight Cherifi | Canadian Food Inspection Agency |

| Nassim Haghighi | Canadian Food Inspection Agency |

| Jacob Seguin | Canadian Food Inspection Agency |

Additional resources

- Understanding the ERA-Food model

- Infographic: ERA-Food model

- Questions and answers: ERA-Food model

- Additional Establishment Information

- Industry eLearning on the ERA-Food model