Acknowledgement

The national livestock, poultry and deadstock biosecurity guidance document is primarily founded on existing sources of biosecurity guidance, manuals and scientific articles. Only direct quotes or data are specifically referenced throughout the document. It is recognized that many sources that have contributed to the general content and biosecurity best practices have not been acknowledged. The committee would like to recognize all contributions from academia, industry, provincial and federal sources.

Table of Contents

1.0 Introduction

The Biosecurity Standard for Livestock, Poultry and Deadstock Transportation was developed to encourage both commercial companies and independent drivers to incorporate biosecurity measures in their transportation practices. It is a resource to create awareness, to educate, to provide a common understanding of biosecurity and to serve as a reference guide for continuous industry improvement. This document is not intended to be adopted by federal, provincial, or territorial governments to be used for law or regulation. Commodity specific farm level biosecurity guidance is available on the Canadian Food Inspection Agency (CFIA) website.

This document focuses on biosecurity for ground transportation but can also be used for air and sea transport events. The information is presented in two sections: The Transportation of Livestock and Poultry and The Transportation of Deadstock and Rendering Material.

It is recognized that not all of the biosecurity guidance provided in this document will be applicable to every transportation event. Similarly, protocols have been provided in the annexes as examples only and may not be directly transferrable between the transportation of different classes of animals or within operations that transport multiple species of livestock and poultry. It is recommended that transporters consider the guidance provided in this document and work with the various industry sectors and consult specialistsFootnote 1 to develop biosecurity protocols that are specific to the transportation event, the species of animal that is transported and animal disease risks.

Some biosecurity best practices may not be achievable due to gaps in infrastructure and the logistics involved in implementing the best practices. Efforts should be made to identify gaps that impede biosecurity implementation, seek alternative approaches to facilitate biosecurity and work on solutions to improve biosecurity for the transportation sector in Canada.

There is a complex interaction between welfare, biosecurity and stress in the transportation of livestock and poultry. All drivers should be aware of and comply with the Codes of Practice for the Care and Handling of Farm Animals, Codes of Practice for the Care and Handling of Farm Animals: Transportation, as well as humane transportation federal regulationsFootnote 2.

1.1 What is biosecurity?

Biosecurity is the implementation of actions that reduce the chance of introducing and spreading infectious agents that cause animal disease and/or the spread of plant pests. Among the many biosecurity measures that can reduce disease transmission are some simple measures that have little or no cost associated with them. You likely are already implementing many good biosecurity practices without realizing it, for example: wearing clean clothes and clean boots, washing your hands with soap and water or using hand sanitizer before and after handling livestock and/or poultry. The cost of a disease outbreak (e.g. depopulation, cleaning and disinfection, reopening export markets, etc.) can far exceed the cost of implementing biosecurity to minimize the risk of introduction and spread of disease.

"An ounce of prevention is worth a pound of cure"

Benjamin Franklin

1.2 Why is biosecurity important to your customer and the agricultural community?

Biosecurity implementation can reduce the chance of introduction and spread of disease, thereby minimizing the impact of disease. Implementation of biosecurity best practices in agricultural activities contributes to maintaining a healthy plant and animal resource base, consumer confidence, public trust, as well as maintaining and accessing new markets and opportunities. Flourishing animal and plant agriculture commodities contribute to supporting or providing the foundation for a healthy transport sector.

Disease and pests can:

- reduce productivity

- reduce the value of animals and products

- reduce domestic consumption

- increase animal health and welfare issues

- increase veterinary and labour costs

- reduce the producers' and transporters' incomes

- close export markets

- negatively impact the environment and human health

1.2.1 Examples of economic impact of commodity specific disease

Disease examples have been provided to emphasize the impact and cost of disease.

1.2.1.1 Porcine reproductive and respiratory syndrome

Porcine reproductive and respiratory syndrome (PRRS) is a viral disease that infects swine and results in poor reproduction, pneumonia in post-weaned pigs, reduced rate of growth and increased mortality in all age groups. In Canada, it is estimated that PRRS costs the Canadian pork industry in the range of $130 million per yearFootnote 3. Transportation is considered an important risk factor for transferring PRRS infection from farm to farm.

1.2.1.2 Porcine epidemic diarrhea

When introduced into naïve populations, porcine epidemic diarrhea virus (PEDv) outbreaks in young pigs can result in mortality rates between 70 and 100%, thereby having a profound effect on the swine sector. In Canada, PEDv was first diagnosed in Ontario in January 2014 and had spread to over 62 farms in the province within six months of the initial detection (Pasma et al., 2016). Cases were also detected in Prince Edward Island, Quebec and Manitoba.

It is estimated that PEDv outbreaks in Canada will cost producers in the range of $243 to $432 per sow, with varying costs depending on management practices (Engele and Whittington, 2014). The recent outbreak of PEDv in the U.S. in its first year (2013–2014) has resulted in loss of more than 10% of total pig population, amounting to approximately seven million piglets. The economic analysis of PEDv outbreak in U.S. has estimated annual losses of $900 million and $1.8 billion for 3% and 6% annual pig loss scenarios, respectively (Paarlberg, 2014).

Various factors, including transportation, have been shown to contribute to the introduction and spread of PEDv. For instance, the surveying of transport units at PEDv contaminated site (e.g. slaughter facilities, assembly yards and auction marts) demonstrated that transport units are at risk of becoming contaminated and spreading PEDv (Yeske et al, 2014; Lowe & Gauger, 2014). To control the spread of PEDv, various governments, industry associations and transporters continue to work together to increase awareness and promote biosecurity.

1.2.1.3 Equine influenza in Australia

In 2007, an equine influenza (EI) outbreak in Australia cost $263 million in government assistance packages and $97.1 million in disease eradication costs (Smyth et al., 2011).

To prevent the disease from spreading throughout Australia, restrictions on horse movements were implemented soon after the disease was confirmed. These movement restrictions lasted eight months and resulted in the cancellation of 261 Standardbred race meetings. This resulted in economic impacts to those who organized and participated in these event, as well as businesses that generate income because of these events (mainly service providers such as catering, hospitality and the transportation industry). The estimated economic impacts for various groups were:

- $23.8 million for the Australian Harness Racing Industry's (includes drivers, trainers, owners, breeders, race clubs and state racing authorities);

- $381 million for households, businesses and horse associations.

1.2.1.4 Avian influenza disease outbreak in 2004

During the avian influenza (AI) outbreak in British Columbia in 2004, 42 commercial poultry farms were infected with the AI virus. In order to stop the spread of the virus, 17 million birds from 125 poultry operations were depopulated (Bowes, 2007). The Government of Canada paid $63.7 million in compensation for birds ordered destroyed (Bowes, 2007).

In addition, the agricultural community sustained a total economic loss of $380.9 million dollars, which included;

- $216.9 million of direct costs to the poultry industry;

- $156 million in economic losses for the poultry service industry (such as truck drivers, live-haulers, catching crews); and

- $7.5 million in one-time losses.

1.2.1.5 Foot-and-mouth disease outbreak in 1952

Canada's last outbreak of foot-and-mouth disease (FMD) was in 1951–1952 in Saskatchewan. Forty-two premises were involved, of which 29 were infected and 13 were considered in contact. The number of livestock destroyed included: 1,313 cattle, 294 swine, 97 sheep, 1 goat, 2,372 fowl and 15,828 eggs.

The eradication costs totalled $1 million, but owing to the ban on exports, the value of livestock fell by $651 million and $70 million was spent in support prices by the Canadian government. The total loss was $722 million plus one year's loss of trade in livestock and livestock products (Sellers & Daggupaty, 1990).

1.3 Significance of transport

With the availability of efficient transportation and advancements in logistical capacity, animals are transported long distances in relatively short timeframes. During the lifetime of some animals, there may be a high frequency of transport events that occurs. For example:

- Horses are highly mobile; some travel on a weekly basis to areas where they commingle with other horses, cattle and wildlife.

- On average, food producing animals have three to four transport events in their lifetime (Serecon Management Consulting Inc., 2015).

- An approximation of 67 million annual transport events for swine and cattle can be made through extrapolation of the data from the PigTrace Canada and Serecon movement study.

- In 2015, 576,053 swine transportation events resulted in the movement of 43.8 million swine throughout Canada (Canadian Pork Council, 2016, see Table 1)

- In 2014, it was estimated that there were over 20 million beef cattle movements (see Figure 1), approximately 4 million dairy and veal cattle movements, and 1.6 million sheep movements (Serecon Management Consulting Inc., 2015).

This data only represents a fraction of the transport events since it does not include data on the poultry, goat, equine or cervid movements. Considering the number of transport events, and that each event provides an opportunity to spread disease, this highlights the need for the transportation industry to implement biosecurity best practices.

The frequency and complexity in the transportation of animals (as illustrated in Figure 1) and deadstock in Canada emphasizes the importance of maintaining animal identification and administrative reports (trip logs) to enable the monitoring of animal movements over large distances and relatively short periods of time. Maintaining the continuity of animal identification during transport events provides the foundation for tracing disease outbreaks back to the source, as well as identifying animals that may have come in contact with infected animals.

| Origin | Destination | Total | ||||||

|---|---|---|---|---|---|---|---|---|

| Farm | Assembly Yard or Auction | Export | Fair | Lab | Slaughterhouse | Render / Disposal | ||

| Farm | 114,013 | 30,636 | 7,983 | 18 | 302 | 391,597 | 21,993 | 566,542 |

| Assembly Yard or Auction | 571 | 2,107 | 2,814 | 2,191 | 292 | 7,975 | ||

| Import | 38 | 6 | 44 | |||||

| Fair | 5 | 1 | 6 | |||||

| Lab | 108 | 161 | 4 | 82 | 355 | |||

| Slaughterhouse | 162 | 967 | 1,129 | |||||

| Render / Disposal | 2 | 2 | ||||||

| Total | 114,735 | 32,910 | 10,797 | 19 | 302 | 393,954 | 23,336 | 576,053 |

Description of Figure 1

Figure 1: This illustrates the transportation of beef cattle as a percentage of the national herd (10.3 million beef cattle representing 76,515 farms, 2013) to various locations throughout the lifecycle of the animal (Serecon Management Consulting Inc., 2015). The individual ID indicates that the person receiving the animals reported individual identification number on the tags applied to an animal. The group ID indicates that the person receiving the animals reported that they received a group of animals, site of origin and species, without providing individual ID numbers. "Unknown" indicates that the person receiving the animals is not required to report animal movements.

Total number of beef cattle = 10.3 million and total number of beef farms = 76,515 (2013).

- Farm 1 (Individual ID) to Export (Individual ID) = 104 (0.51%)

- Farm 1 (Individual ID) to Slaughter (Individual ID) = 75 (0.37%)

- Farm 1 (Individual ID) to Feedlot (Individual ID) = 585 (2.9%)

- Feedlot (Individual ID) to Slaughter (Individual ID) = 1705 (8.5%)

- Feedlot (Individual ID) to Export (Individual ID) = 701 (3.5%)

- Farm 1 (Individual ID) to Auction (Group ID) = 2565 (13%)

- Auction (Group ID) to Feedlot (Individual ID) = 1683 (8.3%)

- Auction (Group ID) to Auction (Group ID) = 24 (0.12%)

- Auction (Group ID) to Slaughter (Individual ID) = 435 (2.2%)

- Auction (Group ID) to Export (Individual ID) = 103 (0.5%)

- Auction (Group ID) to Dealer (Unknown) = 540 (2.7%)

- Auction (Group ID) to Farm 2 (Unknown) = 1210 (6%)

- Farm 1 (Individual ID) to Pastures (Group ID) = 33030 (15%)

- Pastures (Group ID) to Farm 1 (Individual ID) = 3030 (15%)

- Farm 1 (Individual ID) to Fairs (Individual ID) and back to Farm 1 (Individual ID) = 16 (0.08%)

- Farm 1 (Individual ID) to Dealer (Unknown) = 44 (0.22%)

- Dealer (Unknown) to Auction (Group ID) = 59 (0.3%)

- Farm 1 (Individual ID) direct to Farm 2 - Backgrounder (Unknown) = 756 (3.75%)

- Farm 2 (Unknown) to Export (Individual ID) = 120 (0.6%)

- Farm 2 (Unknown) to Slaughter (Individual ID) = 531 (2.6%)

- Farm 2 (Unknown) to Feedlot (Individual ID) = 140 (0.7%)

- Farm 2 (Unknown) to Auction (Group ID) = 1349 (6.7%)

A percentage of movement between Farm 1 to Feedlot, Feedlot to Slaughter, and Farm 1 to Farm 2 occur through Satellite Auctions.

1.4 How are livestock and poultry diseases introduced and spread during transportation?

There is a tendency for people to place an emphasis on biosecurity when disease has been identified. To minimize the chance of disease introduction, biosecurity should be implemented at all times, including when handling animals that appear healthy. Infected animals do not always show signs of disease; they can appear healthy yet still infect other animals and contaminate equipment, vehicles, hands, clothing, footwear and gloves.

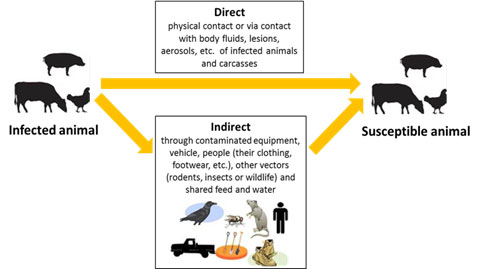

There are two common pathways of disease spread (see Figure 2):

- Direct: Direct transmission to susceptible animals occurs via physical contact with infected animal or carcass (for example; through rubbing, licking, breeding, biting, etc.) or through contact with body fluids (for example; blood, saliva, feces, urine, milk), lesions, aerosols (through coughing, sneezing), and other discharges of infected animal or carcass. This includes livestock or poultry that do not look sick but have the disease and can transfer it to another animal, bird or person (zoonotic diseases);

- Indirect: Indirect transmission involves an intermediate carrier that becomes contaminated and is a source of infection for susceptible animal. The body fluids (for example; blood, saliva, feces, urine, milk,), lesions, aerosols (through coughing, sneezing), etc. from from infected animals or carcasses can contaminate equipment, vehicles, people (including their clothing and footwear), etc. which may subsequently transmit pathogens to susceptible animal who come in their contact.

The pathogens can also be indirectly transmitted through living vectors such as birds, rodents or insects that come in contact with the infected animals or their excretion. Shared feed and water which is contaminated by discharges from infected animals can also indirectly transmit pathogens to healthy animals.

Description of Figure 2

Figure 2: The two common pathways of spread of disease from infected to susceptible animals are: 1) direct transmission from infected to susceptible animals, 2) Indirect transmission through an intermediate carrier.

Spread of disease from infected animal to susceptible animal occur by 1) direct transmission via physical contact or through contact with body fluids, lesions, aerosols of infected animals or carcasses; 2) Indirect transmission occurs through intermediate carriers; for example, vehicles, equipment, people (their clothing, footwear, etc.), other vectors (rodents, insects, or wildlife) and shared feed and water.

The five most common scenarios where disease transmission may occur during a transport event are:

- Loading livestock or poultry into a contaminated transport unit. For example:

- an unwashed or improperly washed transport unit; or

- a transport unit that was contaminated during or following washing.

- Contamination of the transport unit at the premises (either during loading or unloading). For example:

- service personnel vehicles and facility personnel come into contact with the transport unit and/or power unit;

- using or allowing facility equipment to be used inside the transport unit (for example; using a hand barrow, skid steer or tractor from the slaughter facility or farm to remove an injured animal);

- docking the transport unit against a facility; and

- allowing animals that have come into contact with the destination environment (shoots, pens, paddocks) to return to the transport unit during the unloading process.

- Contamination of the premises due to contact with an unclean transport unit/equipment or driver by:

- contact with the premises and with animals that are not to be transported;

- not respecting separation zones or following farm biosecurity protocols; and

- drivers traveling with pets and then entering premises.

- Contamination of the animals in the transport unit at a commingling site. Commingling sites are not just limited to animals—people from farms and other drivers that have been on farms commingle as well, such as at restaurants and truck stops. Additional examples include commingling at:

- a slaughter facility;

- rest stations or areas;

- auctions;

- assembly yards;

- feedlots and transfer docks; and

- events such as competitions and exhibition facilities.

- Animals are exposed to a pathogen due to contact with contaminated personnel or equipment (either during loading or unloading).

- The driver enters the farm or commingling facilities (e.g. offices, restaurants, border customs, slaughter, auction marts, assembly yards) and then enters the power unit and/or animal transport compartment without following biosecurity protocols;

- Other people: Facility personnel (e.g. slaughter, assembly yards, auction marts, catching crews) enter the transport unit and handle animals;

- Contaminated equipment (e.g. handling boards, rattle paddles and shovels, prods, buckets, poultry gates and nets, etc.) are used.

2.0 Transportation of livestock and poultry

This section will focus on biosecurity best practices when transporting live animals. Everyone involved in the transportation of animals or arranging for their transport shares in the responsibility of ensuring the well-being and safety of animals throughout the entire transportation cycle.

2.1 Routine biosecurity measures

The biosecurity measures that are appropriate for a given transportation event should reflect the:

- disease risks associated with transporting animals from or to particular areas or establishments;

- transporters' roles during the transportation phases; and

- logistics, including the availability of biosecurity infrastructure.

The baseline level of biosecurity that's implemented for every transportation event, even in the absence of a client specifying the need for biosecurity, is referred to as the routine biosecurity measures. Routine biosecurity measures are based on basic biosecurity principles. A few examples of basic biosecurity practices are:

- loading animals in clean trailers using clean equipment

- minimizing cross-contamination between trailers and unloading sites or vice versa

- minimizing cross-contamination from clothes and footwear.

Due to variations within the country and between the various commodity groups, it is impractical to define the routine biosecurity measures that would apply to all commodity groups in Canada. It is recommended that transporters refer to the biosecurity best practices in this document and work with industry associations, provincial representatives and veterinarians to establish routine biosecurity measures that are adapted to their specific risks and challenges.

Once routine biosecurity measures are established, transporters are encouraged to share them with their clients and to work with them to ensure that their biosecurity requirements are met. For more information on identifying the client's biosecurity requirements, see section 2.4.1.

2.2 Enhanced biosecurity measures

In situations where disease is suspected or has been identified and there is an increase in risk, then enhanced biosecurity measures are required to prevent disease spread and possibly eradicate the disease from an area. Again, transporters are encouraged to refer to the biosecurity best practices in this document and work with industry associations, provincial governments and veterinarians to establish enhanced biosecurity measures that will address the disease transmission risks.

Examples of enhanced biosecurity measures include:

- designated transport units, equipment and wash facilities for the transportation of diseased animals;

- designated routes that avoid agriculturally dense areas and/or susceptible animal populations;

- specific cleaning and disinfection protocols; and,

- manure and bedding management:

- designated scrape-out locations for conveyances that have transported diseased animals; may be restricted to specific locations that have manure management systems; and

- restrictions for use of the contaminated bedding for other agricultural purposes, such as spreading on fields for fertilizer.

In the event of a reportable, notifiable or disease of economic significance, industry, provincial and/or federal governments will provide specific biosecurity measures for drivers. Biosecurity measures may include movement restrictions and permits.

2.3 Cycle of transportation phases and related activities

The transportation of livestock and poultry is a continuum of activities starting with the completion of one transportation event to the planning and preparing for the next transportation event. For the purposes of this document, this continuum of activities has been described in four separate phases (see Figure 3):

- between loads phase,

- loading phase,

- on the road phase, and

- unloading phase

Description of Figure 3

Figure 3: The relationship between the four phases of transportation: Between Loads, Loading, On the Road, and Unloading. A transportation event can include multiple Loading, On the Road and Unloading phases.

A box in the centre of the diagram with the text, "Multiple loading and unloading sites," has four arrows pointing out to four boxes (above, to the right, below, and to the left). Each box represents a phase of transportation. There are arrows pointing in a clockwise direction between each of the four boxes.

Starting at top of the diagram and moving clockwise, each box contains the following text:

- The between loads phase includes activities following unloading and prior to loading of subsequent load, such as:

- Scraping out

- Cleaning and disinfection of the transport unit and equipment

- Planning for the next transport event (what, where and when)

- The loading phase includes activities to load animals into the transport vehicle, generally on-farm or at an intermediary location, such as:

- Accessing the site

- Entering & exiting the power unit

- Entering the trailer

- Applying bedding & assisting with loading

- Exiting the trailer and re-entering the power unit after handling animals

- The on the road phase includes activities between the point of loading and unloading, such as:

- Selecting a route

- Stops

- Rest stations

- The unloading phase includes activities related to removing animals from the transport unit at destination, such as:

- Accessing the site

- Entering and exiting the power unit

- Entering the trailer

- Exiting the trailer and re-entering the power unit after unloading animals

- Scraping out (at destination)

2.4 Between loads phase

The Between Loads Phase of transportation encompasses the following activities:

- identifying the customer's biosecurity requirements;

- cleaning and disinfection, which includes:

- removal of organic matter; and

- the inactivation of pathogens

- planning and preparing for the transportation event.

2.4.1 Customer's biosecurity requirements

Customers may have biosecurity requirements specific to their risk tolerance, animal production type and business model. These requirements are often in addition to the transporter's routine biosecurity measures. The customer's biosecurity requirements may include but are not limited to:

- use of a transport unit that is designated to transport a specific type of animal with a specified health status;

- a timeframe of non-use (commonly referred to as downtime) after cleaning and disinfecting the trailer;

- the identification of specific truck wash stations to be used;

- the use of specific cleaning and disinfection protocols, including:

- third party validation of cleaning and disinfection;

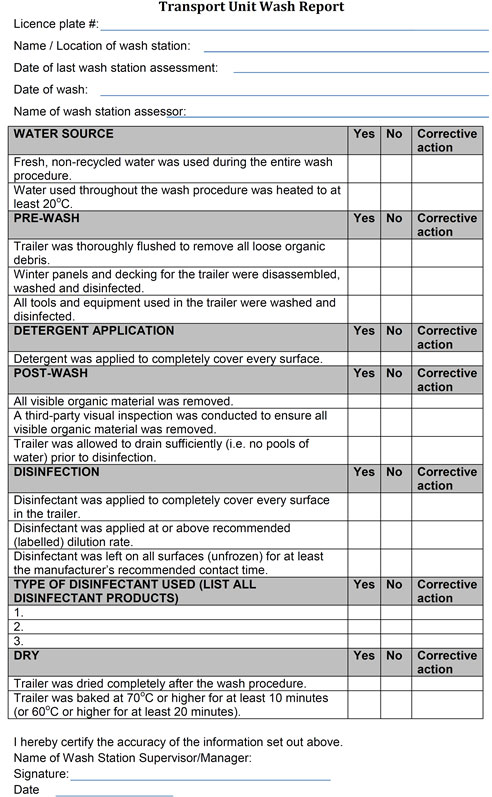

- provision of a transport unit wash report (see Annex 1: Transport unit wash report);

- specifying the driver's involvement in loading and unloading;

- specifying where to park on the premises and the route, including the driver's stops, and rest stations; and,

- scrape-out location.

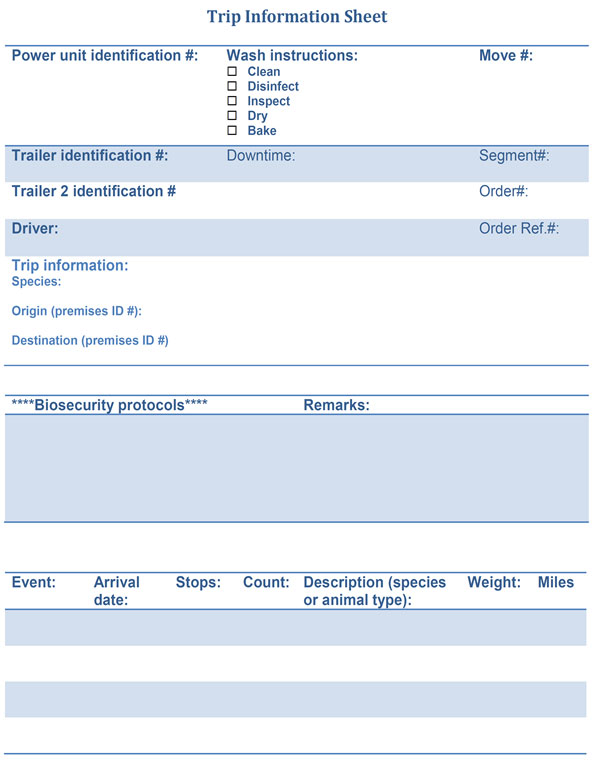

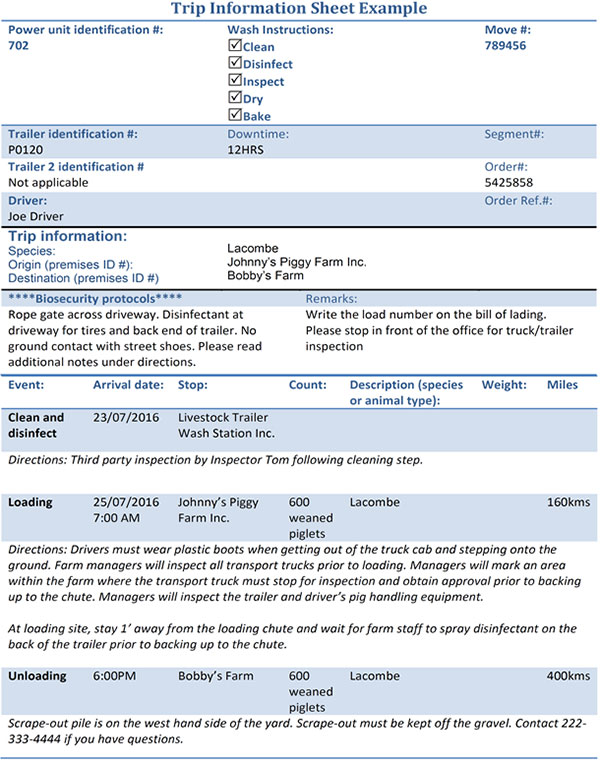

A trip information sheet is a tool commonly used by transport companies to communicate customer biosecurity requirements to the driver. A template and an example of a customer's additional biosecurity requirements has been provided in Annex 2a: Trip information sheet and Annex 2b: Trip information sheet example, respectively.

The early identification of the customer's biosecurity requirements allows drivers to ensure that they have the required biosecurity supplies, documentation and equipment for the transportation event.

Biosecurity best practice

- Implement routine biosecurity measures at all times.

- Identify the customer's biosecurity expectations early in the planning phase.

Encourage the uptake and implementation of biosecurity within industry by practicing routine biosecurity measures at all times, even in situations where the customer has not identified any biosecurity requirements. For assistance, refer to the following sections in this document: Why is biosecurity important to your customer (section 1.2) and the Significance of transport (section 1.3).

2.4.2 Cleaning and disinfection

This section describes:

- biosecurity principles for cleaning and disinfection

- biosecurity considerations when choosing a wash station

- storage of transportation units following cleaning and disinfection

- record-keeping for cleaning and disinfection

Biosecurity best practice

- Perform the cleaning and disinfection steps necessary to optimize the reduction or inactivation of pathogens to reduce the risk to an acceptable level.

Protocols and best practices may not apply to all transportation events and are not directly transferrable between the transportation of different classes of animals or within operations that transport multiple species of livestock and poultry. It is recommended that drivers and transport companies consult specialistsFootnote 5 to develop cleaning and disinfection protocols that are specific to the transport unit and the species of animal that is transported.

This section will focus on the general biosecurity principles for cleaning and disinfection. Biosecurity best practices for cleaning and disinfection, as well as cleaning and disinfection example protocols have been provided in the annexes, see:

- Annex 3: Biosecurity best practices for cleaning and disinfection

- Annex 4a: Example of a wash bay protocol for livestock transport units

- Annex 4b: Example of a truck and crate cleaning and disinfection standard operating procedure in a slaughterhouse

- Annex 4c: Example of a cleaning and disinfection protocol for equine trailers at a wash station

2.4.2.1 Biosecurity principles for cleaning and disinfection

Biosecurity protocols may not include all of the cleaning and disinfection steps identified below – ultimately the combination of steps and frequency will be based on the level of risk. The level of risk varies considerably based on a number of factors, such as type and nature of the pathogen(s), species, herd or flock health status. To illustrate the progressive effectiveness of combining process steps, a percentage of pathogen load reduction for each step has been provided. The percentage is based on extrapolated data from existing reference materialFootnote 6.

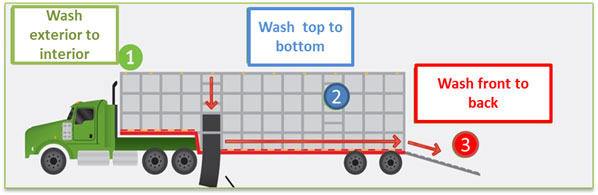

Removal of organic matter

- Cleaning – involves a dry phase to remove the organic matter (primarily bedding and manure) commonly referred to as "scrape-out", and a wet phase involving a high volume of clean water to flush out organic matter that remains after scraping out. Pressure washing is not recommended to remove the organic matter during the cleaning phase as it tends to scatter the organic matter within the transport unit rather than flush it out. Proper attention to dry cleaning will make the washing step much easier. The combined effort of dry and wet cleaning could result in a seventy-five percent (75%) reduction in pathogen load.

- Washing – involves the application of a solution of clean water and detergent or degreaser at low pressure to disrupt biofilms and loosen organic material on surfaces. After the organic material is thoroughly saturated, continue washing using a low to medium pressure spray of water to dislodge or loosen the biofilm and organic matter; mechanically scrubbing or scraping surfaces with brushes, brooms or scrapers may be required. The effluent (detergent and biofilm) is then removed from the unit using clean water.

Washing is not complete until organic matter has been completely removed from all surfaces. It may be necessary to wash the transport unit several times to remove organic matter. Removal of organic material and detergent residues is important to ensure chemical disinfectants are not inactivated during the disinfection step. Removing all organic matter and using detergent to wash a transport unit has been shown to result in an 80% reduction in pathogen load.

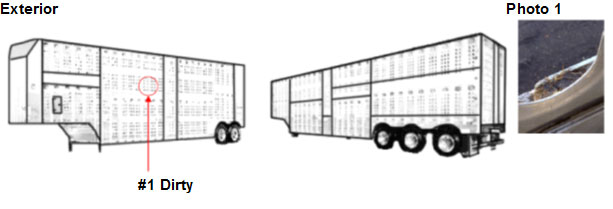

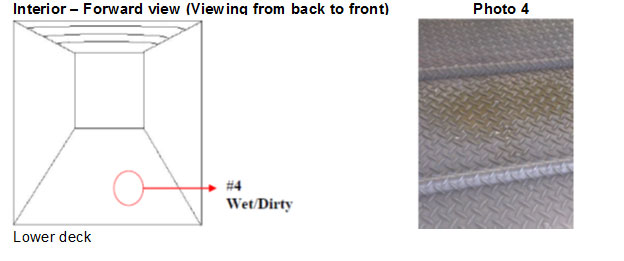

- Visual inspection of all surfaces is completed to ensure that all organic matter has been removed. This is best done when rinsed water is drained away. See Annex 5a: General visual inspection checklist and 5b: Example of a visual inspection form used for swine transport units.

Inactivation of pathogens

Disinfection, drying (natural or thermal assisted) and baking are steps that help to inactivate pathogens.

- Disinfection – most commonly this involves the application of a chemical at a specific concentration for an identified time period. The type of disinfectant will depend on the pathogens of concern. The concentration will depend on the objective of this step. Some of the disinfectants at lower concentrations can be used for cleaning, while a higher concentration is needed to achieve disinfection. Surfaces must be visibly clean, without pooled water and dry (if possible) prior to applying a disinfectant and the disinfectant must stay wet and fully cover the surface for a specific amount of time to achieve the desired pathogen inactivation or reduction. As temperatures drop below 10°C many chemical disinfectants require an increased contact time and concentration to achieve effective disinfection. As temperatures approach 0°C, cleaning and disinfection should be performed in a heated building or using antifreeze agent. Review disinfectant labels, follow the manufacturer's directions and contact the manufacturer if guidance is required. Disinfectants may be applied by different applications (e.g. spraying or foaming). When used properly, applying a disinfectant has been shown to reduce the pathogen load by over 99%.

- Drying involves natural drying or using thermal assisted processes to ensure that all moisture has evaporated from the transport unit. This additional step ensures that pathogens that may have escaped contact with the disinfectant and that are susceptible to desiccation are inactivated.

- Baking, a thermal process used to inactivate pathogens, may be recommended for some pathogens that escape contact with the disinfectant and require high temperatures to be inactivated. It is acknowledged that there are few facilities with this capability in Canada.

Cleaning and disinfection protocols may involve a combination of the disinfection, drying or baking steps for the inactivation of pathogens. The nature of the pathogen, condition of the transport unit, customer's biosecurity requirements and lack of scientific evidence are just some of the reasons that other inactivation steps, in addition to disinfection, may be required. For example, other inactivation methods, such as thermal assisted drying or baking are recommended when:

- damaged equipment (e.g. damaged or frayed rubber matting or docking bumpers) or the design of the trailer or compartment (e.g. open tubing or gaps) prevents surfaces from coming into contact with the disinfectant;.

- conditions do not allow the disinfectant to be applied in accordance with the manufacturer's directions.

2.4.2.2 Biosecurity considerations when choosing a wash station

It is recognized that biosecurity infrastructure, wash station capacity and cleaning and disinfection protocols vary between wash stations. When feasible, incorporate biosecurity criteria when selecting a wash station to ensure that the wash station:

- can achieve the required level of cleaning and disinfection of the transport unit and associated equipment;

- has identified routes for the site that respect segregation of clean transport units from contaminated units in dirty areas; and,

- has protocols in place that minimize the risk of cross-contamination between transport units.

For detailed guidance refer to Annex 6: Biosecurity guidance for choosing a wash station.

Biosecurity best practice

- Incorporate biosecurity criteria when selecting a wash station.

- Choose a wash station that has the infrastructure and capacity to achieve the required level of cleaning and disinfection.

- Choose a wash station that is designed, organized and maintained in a way that ensures that there is no cross-contamination.

The implementation of biosecurity best practices at wash facilities contributes to:

- increasing drivers' capacity to meet their customer's biosecurity requirements;

- minimizing the risk of the wash station being the source of, or contributing to, contamination of the transport unit; and

- the capacity of industry and provincial and federal governments to mitigate the risk of introduction and spread of disease, which assists in the control and eradication of diseases.

2.4.2.3 Storage of transportation units following cleaning and disinfection

Once a transport unit has been cleaned and disinfected it is important to keep it clean prior to loading. Ideally, transport units should be stored in an area that is:

- physically and functionally separate from transport units that have not been cleaned or disinfected.

- away from pets, farm animals, rodents and wildlife.

- away from people, contaminated equipment, feed and bedding.

- away from exhaust fans and dusty areas.

Biosecurity best practice

- Keep transport units clean prior to loading.

2.4.2.4 Record-keeping for cleaning and disinfection

Drivers, transporter companies and wash facilities should maintain up-to-date records for cleaning and disinfection of the transport unit. Good record-keeping and written protocols provide the ability to evaluate, verify and modify biosecurity programs for transportation events over time. See Annex 1 for an example of a transport unit wash report.

2.4.3 Planning and preparing for the transportation event

Factors that will influence the preparation required for the transportation event include:

- number of loading and unloading sites;

- driver's involvement in loading and unloading animals;

- location for scrape-out;

- route;

- driver stops, which may include:

- weigh stations;

- gas stations;

- restaurants; and

- border crossings.

2.4.3.1 Multiple loading sites

From a biosecurity perspective, the ideal transport event includes a single loading and unloading site since the risk of disease contamination and spread increases significantly with each loading and unloading event. It is recognized that this is not always practical or economical. Regardless, drivers and customers should both be aware of the risks and the biosecurity best practices that mitigate the risks associated with multiple loading and unloading sites.

Physically separating animals within the transport unit does not adequately mitigate the risk of infectious disease spread between animals within a trailer. For this reason, the contamination status of the transport unit is reflected by the lowest health status of the animals loaded into the trailer. For multi-loading and unloading sites, the biosecurity best practice is to only load animals that have an equivalent health status.

Biosecurity best practice

- Only load animals that have an equivalent health status.

- Always travel from sites with a higher health status to those with a lower health status

In addition, the risk that the driver and transport unit may become contaminated increases with each loading and unloading event. This in turn increases the risk that the transporter might spread disease at loading and unloading sites. Always travel from sites with a higher health status to those with a lower status. Note that this biosecurity best practice alone offers limited protection. Diseased animals don't always show signs of disease, and customers may not always know or share the disease status of their animals with the driver.

The driver's vigilance in employing the biosecurity best practices throughout the transportation event is crucial in helping prevent disease spread. With the increasing complexity of logistics, likewise there is an increase in the complexity of the biosecurity measures required.

2.4.3.2 Obtain biosecurity equipment and supplies

The amount and type of biosecurity equipment required for a particular transportation event is dependent on the following:

- The number of loading and unloading sites.

- The amount of interaction that the driver will have with the animals, equipment and staff at the loading and unloading sites.

In all cases, it is recommended that the biosecurity equipment contain the supplies required to either clean and disinfect footwear between sites or include at least one pair of footwear (or disposable boot covers – as personal safety considerations allow) and gloves for each loading and unloading site. In situations where the driver will be involved in the loading and handling of animals, the recommendation is that the biosecurity kit include (see Figure 4):

- clean footwear designated to the power unit;

- rubber boots that can be cleaned and disinfected;

- new, freshly laundered cloth or disposable coveralls;

- gloves;

- hat;

- large disposable garbage bags to store used dirty clothing and other reusable items that need to be laundered and cleaned;

- disinfectant and hand sanitizer;

- paper towel; and

- water and wash bucket.

Ensure that the equipment required for the transportation event is either new or has been cleaned and disinfected. Additional equipment may include:

- animal handling equipment such as poultry gates and nets, rattle paddles, shakers and chase boards;

- a shovel for scraping out the trailer following the transportation event; and

- equipment required to secure the load.

Prevent contamination of your equipment by storing clean equipment in a clean location on your transport unit (for example, a tote or plastic bag that can be closed and kept separate from dirty equipment).

2.4.3.3 Documentation related to biosecurity for a transport event

The documentation requirements for any given transportation event will vary depending on the type of movement and the customer's requirements. From a biosecurity perspective, electronic document exchange is preferred over providing customers with hard copies. When hard copies of documents are required they should always be stored in a clean location.

Exports, imports and interprovincial transportation events may require specific documentation and in some situations, the documentation must accompany the load. Examples of the type of documentation required for these types of movements include; import permits, permits to transport or move, animals transfer documents, animal health records and/or export certificates. Ensure that the required documentation has been obtained prior to leaving.

The driver/transporter should have all the relevant documents readily available during transportation. It may include following:

- transport unit wash report (see the example provided in Annex 1: Transport unit wash report)

- trip information sheet (see Annex 2a: Trip information sheet template and Annex 2b: Trip information sheet example)

- verification and validation of wash protocol

- visual inspection after washing (see Annex 5a: General visual inspection checklist and Annex 5b: Example of a visual inspection form used for swine transport units)

Additional documentation that the driver might have to provide includes:

- veterinary certification;

- animal identification (e.g. a tag, tattoo or chip) to allow animal traceability to the premises of departure and, where possible, to the premises of origin;

- details of any animal's condition that may be a risk (e.g. history of disease, stage of pregnancy);

- documentation of the period of location, period of rest, access to water and feed while on the road; and, disclosure of transport history. The following documentation templates are available in:

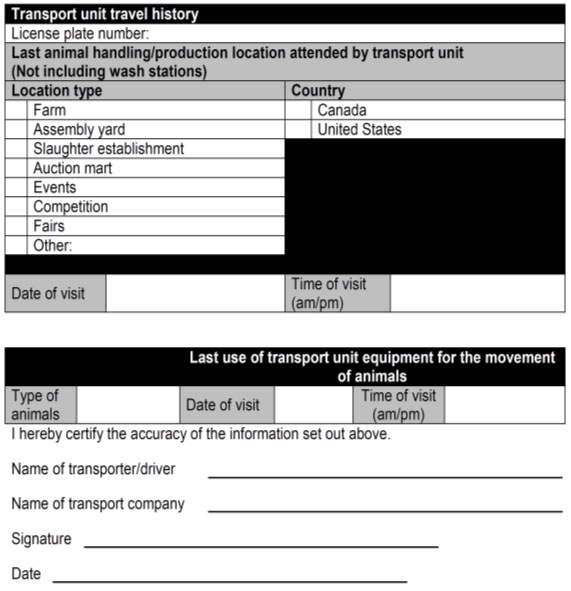

- Annex 7a: Disclosure of transport history

- Annex 7b: Transport unit travel history

2.4.3.4 Obtain bedding and feed

Bedding can be obtained prior to leaving for the transportation event or at the loading site. Bedding and feed can transport pests such as the cereal leaf beetle. Prior to loading bedding or feed into the transportation unit, ensure that it is clean, free of contaminants and that it is not a risk of introducing plant pests to another area or region. It is recommended that bedding and feed be obtained from a reputable commercial supplier.

Obtain confirmation from the supplier that validates the bedding or feed is dry, free of wildlife droppings and feathers, and was stored in an appropriate pest monitored location.

Cereal leaf beetle

The risk of spreading cereal leaf beetle to western Canada during efforts to provide feed from eastern Canada to animals during the drought in 2004 was significant. The potential introduction of cereal leaf beetle to western Canada threatened trade with the USA of an estimated $500 million in cereal crops annually.

In addition, once obtained from a supplier, it is recommended that bedding be stored in a clean secure area where it does not come into contact with animals (wild animals, rodents, birds or farm animals) and contaminated equipment or personnel.

2.4.3.5 Driver preparation

Drivers can be a source of contamination, especially if they've come into contact with pets, farm animals, wildlife or contaminated equipment. Before leaving for a transportation event, it is recommended that drivers:

- wash and wear freshly laundered clothing;

- wear clean footwear; and

- avoid contact with any animals (including pets) or wildlife.

Do not travel with your personal pets in the power unit. Personal pets are not trained to respect biosecurity requirements; contaminated paws and fur present the same risk as contaminated footwear, hands and clothing.

2.5 Loading phase

The various types of animal containment systems (trailer vs. crates or compartments), as well as the variance in driver involvement in loading, creates challenges in providing biosecurity guidance that will apply to all transport events. It is important to assess the guidance provided and use your judgment to determine whether it applies to a specific transportation event.

The loading phase includes the following activities:

- Accessing the site

- Entering and exiting the power unit

- Preparing the trailer for loading

- Applying the bedding and loading animals

2.5.1 Accessing the site

When accessing the site, always follow the premises biosecurity protocols. Pay attention to instructions (see Figure 6) provided by the customer on how to access the site, where to pick up bedding (if applicable), parking and signing visitors' logs (if applicable).

Description of Figure 6

Figure 6: Two examples of signage indicating that biosecurity is in effect and must be respected.

Two photographs side-by-side. The photo on the left is an octagon shaped sign with the text, "No unauthorized pedestrian or vehicle traffic. Stop. Controlled access zone Biosecurity in effect." The photo on the right is a sign that reads, "Visitors, Please respect farm biosecurity. Please contact the manager before entering. Phone:  . Do not enter property without prior approval. Keep to roadways and laneways."

. Do not enter property without prior approval. Keep to roadways and laneways."

The customer may request additional biosecurity measures prior to accessing the loading site. Examples may include:

- cleaning and disinfecting the back of the transport unit prior to making contact with the loading site; and

- cleaning and disinfecting wheels and wheel wells.

Encourage customers to maintain access routes that are free of manure and/or mud or snow. Organic matter, potentially infected with pathogens can accumulate on wheels, wheel wells and the undercarriage, if access routes are contaminated and not poorly maintained. In circumstances where there are no biosecurity protocols on site, at a minimum you should:

- avoid roadways or laneways contaminated by manure or organic matter.

- drive slowly to minimize dust, manure and/or mud from contaminating the transport unit.

- park in the area designated for loading.

- Avoid parking by exhaust fans and air inlets (if possible).

Caution

Always follow the premises biosecurity protocols when on site.

2.5.2 Entering and exiting the power unit

When entering and exiting the power unit, avoid contaminating the interior via the implementation of biosecurity practices. Pay particular attention to contamination via hands, clothing and footwear. One way to avoid contaminating the interior of the power unit is by wearing clean clothing, having dedicated footwear for the power unit (driving shoes) and by having separate footwear for exiting the power unit. Always wash your hands prior to entering the power unit or use hand sanitizer prior to touching anything in the interior of the power unit. An example of protocol for entering and exiting the power unit and trailer is available in Annex 8.

2.5.3 Preparing the trailer for loading

When preparing the trailer for loading, it is important to minimize the risk of contamination to the interior of the trailer or crates. Consider people, equipment and things required for loading and put in place biosecurity measures to prevent the contamination of the trailer or crates. For example;

- Place crates in a clean area.

- Do not allow potentially contaminated premises or facility staff or equipment to enter the trailer.

- Do not come into contact with animals that are not involved in the transport event.

2.5.4 Entering the trailer

Follow biosecurity best practices when leaving the power unit and entering the trailer to prevent contaminating the inside of the trailer. It is recommended to wear a clean outer layer of clothing, hat, boots and gloves that are dedicated to tasks performed in the trailer. Store clothing, hats, boots and gloves in a clean location (such as a clean tote or bag) to ensure that they do not become contaminated prior to being used.

Clean and sanitize hands prior to entering the trailer and handling animals for loading, as well as prior to re-entering the power unit. Refer to Annex 8 for an example of protocol for entering and exiting the power unit and trailer.

Biosecurity best practice

- When performing tasks in the trailer, wear clean clothing, hat, footwear, gloves and use loading equipment that is dedicated to the trailer.

2.5.5 Applying the bedding and loading animals

Once in the trailer, apply clean bedding to areas where animals will be loaded. If bedding is provided at the loading site, then ensure that the bedding is dry and clean (e.g. free of contaminants or pests, feces and dirt).

During loading:

- follow onsite biosecurity protocols, including complying with restricted access on entry, such as demarcation at loading zones.

- prevent backward movement of livestock or bedding/manure from transport unit when loading.

- avoid contact with the animals that are not associated with the transportation event.

2.5.5.1 Compromised animals

Transporters have the right to refuse to load any animal they deem is compromised or unfit for transport. For a list of conditions, please refer to Transporting unfit or compromised animals.

Compromised animals can only be transported directly to the nearest suitable place where they can receive care or be humanely killed (does not include an assembly center), and special transport conditions must be applied.

Unfit animals can only be transported to a place to receive veterinary care, following a veterinarian recommendation and special transport conditions must be applied.

If there are concerns with loading a compromised or unfit animal, refer to the humane transportation federal regulations (Part XII of the Health of Animals Regulations), the Interpretive Guidance for Regulated Parties and the species specific codes of practice (see Codes of Practice for the Care and Handling of Farm Animals).

2.5.6 Exiting the trailer and re-entering the power unit after handling animals

The exterior layer of clothing, hands (either exposed hands or gloved), hat and footwear (designated boots or boot covers) will be contaminated after having handled animals during loading. Without biosecurity measures, the power unit becomes a commingling site for any bacteria, virus or fungi that you have been exposed to either by handling an animal or by contact with the environment.

Biosecurity best practice

- After having handled animals during loading, remove the outer layer of clothing, hat, footwear and gloves and sanitize hands prior to re-entering the power unit.

The ideal biosecurity practice prior to re-entering the power unit at the conclusion of loading after having handled animals is to remove the outer layer of clothing, footwear, and gloves. If the articles are disposable, check with the customer and, dispose of them onsite if possible. Otherwise, contain the articles in a sealable container such as a garbage bag or tote, prior to loading them into a compartment of the transport unit. Sanitize hands prior to entering the power unit and sanitize all contact points within the power unit once you've entered. Refer to Annex 8 for example of protocols on exiting and entering the power unit and trailer.

2.6 On the road phase

While on the road, there is a risk of introduction and spread of disease if you park in close proximity to other animals that are carrying disease or if disease has been identified on premises in close proximity to the route you are travelling. It is important to keep records to document the route travelled, stops made and animal rest stations. Biosecurity can play an important role in mitigating the risk of disease when:

- selecting a route;

- stopping; and,

- at commingling sites.

2.6.1 Selecting a route

The sequence of pick up or delivery should take into consideration the risk of disease transmission (for example; animals of high health status should be loaded first as not to arrive at such premises with a contaminated transport unit). Loading animals of lower health status when transporting with a higher health status will reduce the health status of the high health animals and may also put them at risk of disease. Loading young animals with older animals may also create a risk of spreading disease to the young animals since they could be less immunocompetent (i.e. they're more likely to become sick if exposed to pathogens).

Biosecurity best practice

- Avoid agriculturally dense areas and areas where disease has been identified.

Where possible, avoid agriculturally dense areas and avoid areas where a disease has been identified, particularly if the disease has been identified in the same type of animals being transported. Various tools are being developed by industry associations and provincial governments to make the agricultural community aware of high risk areas in the event of a disease outbreak.

2.6.2 Stops

Stops can include border crossings, restaurants, gas stations and weigh stations. Stops can be a source of contamination for the driver, transport unit and, if stopped in close proximity to other animals, it could result in the direct transfer of pathogens to the animals being transported. Some commodity sectors have developed specific protocols for various types of stops, for example border crossings (refer to Annex 9: Example of transport boot protocol to follow when entering and exiting the power unit at high-risk stops). The following biosecurity best practices are recommended at all places a driver may stop:

- park as far away as possible from other animal transport units.

- follow biosecurity best practices when entering and exiting the power unit (see section 2.5.2 – Entering and exiting the power unit).

- discourage people from touching or handling the animals being transported.

2.6.3 Rest stations

In some situations, livestock will be unloaded to rest at some point during the transport event. Rest stations can pose a biosecurity risk since these locations may be frequented by animals of unknown health status. In addition, some rest stations have limited capacity and infrastructure to support the implementation of basic biosecurity measures (e.g. no running water, limited effectiveness in cleaning and disinfecting of animal holding areas such as stalls and paddocks).

Plan in advance and consider the site's capacity for mitigating biosecurity risks when choosing rest stations. If possible, identify rest stations that have health status requirements and request information on potential risks such as previous tenants, disease concerns and biosecurity protocols implemented between tenants, including the cleaning and disinfection protocol used in areas where animals will be kept. Ensure that the rest station has a scrape-out site available.

At commingling sites, give biosecurity consideration to other vehicles, access pathways, the ground type and conditions, equipment, other animals and people. At rest stations, follow additional biosecurity practices to those recommended for stops (see section 2.6.2):

- avoid sharing or using communal equipment (such as shovels, buckets for feed or water, pitch forks, ropes) available for use on site, or clean and disinfect equipment prior to use.

- keep animals segregated from animals of unknown or lower disease status.

- unload and keep your animals in an area that has been cleaned and disinfected.

2.7 Unloading phase

The driver is responsible for the animals until they are unloaded at the destination. The following biosecurity best practices, previously identified in the section on loading (see section 2.5), also apply to unloading:

- Accessing the site

- Entering and exiting the power unit

- Entering the trailer

- Exiting the trailer and re-entering the power unit after unloading animals.

During unloading:

- follow onsite biosecurity protocols (refer to unloading biosecurity requirements recorded in Annex 2a: Trip information sheet), including complying with restricted access on entry, such as demarcation at unloading zones.

- prevent backward movement of livestock, bedding and manure back into transport unit when unloading.

For livestock, the driver may need to unload animals that are injured, sick or dead at destination. If specialized equipment is required to remove these animals, attempt to clean and disinfect them as much as possible prior to use in your conveyance.

The perception that biosecurity requirements are not needed for animals being transported to a final life cycle destination, such as a slaughter facility, is short-sighted. The risk of transmitting pathogens associated with the transport event is equivalent to other commingling locations or even higher. The slaughter establishment and equipment has the potential to be a source of contamination for transport units, drivers and equipment that will be used to move healthy animals.

2.7.1 Scraping out at destination

From a biosecurity perspective, the biosecurity best practice includes scraping out at the unloading site because it:

- allows bedding and manure to be removed following unloading;

- eliminates the need for the driver to go to an additional location just to scrape-out.

Cleaning and disinfection following scrape-out is highly recommended since scrape-out locations can serve as important contamination points.

For biosecurity best practices during scrape-out, refer to Annex 3.1 – Scrape-out.

3.0 Transport of deadstock and rendered material

This section will provide biosecurity guidance that specifically applies to the transportation of deadstock throughout the four phases of transportation (between loads, loading, on the road, and unloading). Many of the biosecurity best practices that are highlighted in section 2 will also apply to this section. In the interest of avoiding redundancies, the reader will be referred to specific sub-sections of section 2 Transport of livestock and poultry when appropriate.

Biosecurity is important when transporting deadstock because deadstock can remain infectious long after an animal has died, and contact with deadstock, their bodily fluids and secretions may transmit pathogens to live animals. Once decomposition begins, liquefied tissues and bodily fluids escape from the body, these fluids, which may be infectious, can be difficult to contain and can easily contaminate the environment, drivers, equipment and the transport unit.

Consider all deadstock pick-up sites as potential source of infection.

These sites are considered high risk whether it is a pile next to a production unit, slaughter facility, salvaging facility or approved provincial or municipal collection site. Deadstock transport units, associated equipment and drivers pose a biosecurity risk to live animal production. For this reason, to mitigate biosecurity risks associated with deadstock collection, it is recommended that deadstock pick-up sites be located away from production sites and have physical barriers and biosecurity protocols.

Ideally, but practically or economically unviable, deadstock transportation events would include a single loading and unloading event. Typically, it is more economically feasible for deadstock transportation events to include several loading locations in one transport event (e.g. multiple farms, slaughter establishments, salvaging facility or other approved provincial or municipal collection sites).

Some provinces and municipalities have legislative requirements associated with the handling and transportation of deadstock to address environmental considerations and social and biosecurity concerns. Deadstock trasnporters are responsible for making sure that they are aware of and are in compliance with these legislative requirements. Since the objective of this document is to provide biosecurity guidance, environmental considerations, public trust and legislative requirements associated with the transportation of deadstock will not be addressed in this section.

Note: There are federal rules governing the transport of cattle (or other bovine animal) from which Specified Risk Material (SRM) has not been removed. SRM refers to certain cattle tissues capable of transmitting bovine spongiform encephalopathy (BSE). For information regarding SRM permits, refer to the Canadian Food Inspection Agency website.

3.1 Risks associated with deadstock transportation

The three biosecurity risks associated with deadstock transportation include:

- contamination of the driver or transport unit during the loading and unloading phase;

- contamination of the production site or premises by the driver or transport unit during the loading and unloading phase; and,

- contamination of the environment when on the road and between loads phases.

In situations where disease is suspected or has been identified and there is an increase in risk, then enhanced biosecurity measures are required to be adopted by the deadstock transporters. The deadstock transporters are encouraged to refer to the biosecurity best practices in this document and work with industry associations, provincial governments and veterinarians to establish enhanced biosecurity measures that will address the disease transmission risks. Examples of enhanced biosecurity measures include:

- designated transport units, equipment and wash facilities for the transportation of deadstock from infected premises;

- designated routes that avoid agriculturally dense areas and/or susceptible animal populations; and

- specific cleaning and disinfection protocols.

3.2 Transport unit design

The transport unit design and construction can help mitigate the biosecurity risks associated with the transportation of deadstock. It is recommended that deadstock transport units (includes the power unit, trailers, containers and loading equipment) be:

- designed in a manner that allows for cleaning and disinfection (including the wheel wells, undercarriage etc.); and

- constructed from materials that can withstand repeated cleaning and disinfection.

It is also recommended that trailers and containers used to transport deadstock be:

- contained – leak- and spill-proof; and

- covered or closed to prevent access by scavengers.

Biosecurity best practice

- The deadstock transport unit is designed and maintained to contain carcasses and fluid.

- The transport unit and associated equipment can be cleaned and disinfected.

3.3 Between Loads Phase

The between loads phase of a transportation event includes the following:

- Cleaning and disinfecting the transport unit following the previous transportation event;

- Planning for the next transportation event:

- identifying pick-up and drop-off locations;

- considering the biosecurity protocols of customers;

- identifying and assessing biosecurity risks;

- planning your route;

- ensuring that you have required supplies for the next transportation event.

3.3.1 Cleaning and disinfecting the transport unit following the previous transportation event

After unloading at destination (licensed disposal facility or authorized site), it is recommended that the transport unit and associated equipment be cleaned and disinfected. Ensure that the disinfectant that is used will be effective in inactivating potential pathogen(s). The cleaning and disinfection process includes:

- removing or taking apart equipment (e.g. hoses and chains) so that they can be cleaned and disinfected;

- disposing of any equipment that may have been exposed to contaminants and can't be cleaned and disinfected;

- cleaning the transport unit to remove all loose organic matter and then washing it using a detergent;

- inspecting the transport unit and associated equipment to ensure organic matter has been completely removed following the cleaning step; and,

- applying a disinfectant at the right concentration and contact time. Follow manufacturer's instructions when storing, mixing and applying disinfectants.

For more information, refer to the subsection 2.4.2 Cleaning and disinfection.

Biosecurity best practice

- The transport unit and equipment must be completely cleaned and disinfected following each transportation event (i.e. at the completion of the route and unloading of the deadstock).

3.3.2 Planning for the next transportation event

When planning for the next transportation event, consider the customer's biosecurity protocol. For new customers, discuss biosecurity and obtain their deadstock protocols. Consider the following:

- cause of death (if known) and any medical treatment.

- the location of deadstock, specifically whether the deadstock are located:

- within an animal holding facility;

- next to an animal holding facility; or

- away from animal holding facilities.

- the customer's biosecurity protocols; such as

- the use of dedicated access routes.

- whether access pathways are clean and kept free of mud, manure and other organic matter.

- whether the driver is required to handle the deadstock and/or remove them from the production area.

- the level of decomposition of the animals (fresh dead vs. in decomposition)

- whether the deadstock are stored in a leak-proof container.

Recognizing that a lot of the logistics are dependent on the economics of deadstock collection, consider biosecurity risks when planning your route. Typically it is preferable to either dedicate a trip to collect high risk deadstock or to collect them last. High-risk deadstock includes those:

- that may have succumbed to an infectious disease; and

- from a premises identified as infected by industry and/or provincial or federal authorities.

In addition, when there's a greater likelihood that the transport unit or driver will become contaminated during loading then the recommendation is to collect deadstock from that site last so that you don't risk contaminating the next collection sites. These situations include those where;

- access pathways are contaminated with manure and other organic matter; and

- the deadstock are fresh dead vs. in decomposition and cannot easily be loaded into the transport unit (i.e. the deadstock are not stored in a contained bin).

In situations where the driver or transport unit could pose a risk of contaminating the production site, the recommendation is to dedicate a trip to the collection of deadstock from that site or go to that site last. An example would be when the driver must enter the production site to remove deadstock. Although it is recommended that the driver not enter animal holding sites to limit their exposure to contaminated material and prevent contamination of production sites; it is recognized that it may be required in situations where not all customers will have the equipment required to remove deadstock from their facility.

If the driver is required to handle deadstock, then it is recommended that they bring the following for each site:

- a disposable outer layer of clothing or one that can be cleaned and disinfected;

- disposable gloves;

- hats; and,

- boot covers and/or boots that can be cleaned and disinfected prior to re-entering the transport unit.

If handling of deadstock by the driver is not required, then it is recommended that they bring:

- disposable gloves; and,

- boot covers and/or boots that can be cleaned and disinfected prior to re-entering the transport unit.

Store clothing, hats, boots and gloves in a clean location (such as a clean tote or bag) to ensure that they do not become contaminated prior to being used.

3.4 Loading Phase

The customer has a role in deadstock management prior to collection, which can significantly impact the biosecurity consideration for the driver, including:

- timely deadstock removal before the carcasses reach an advanced state of decomposition;

- type and condition of deadstock storage:

- secure from scavengers;

- leak-proof;

- ease of loading from contained unit.

- ensure location of deadstock storage:

- is situated away from production sites;

- has dedicated clean access and egress pathways for the deadstock transport unit; and

- has dedicated pathways for equipment and staff associated with the production site.

3.4.1 Accessing the deadstock collection site

When accessing the deadstock collection site, always follow the premises biosecurity protocols. Refer to biosecurity best practices outlined in the subsection 2.5.1 – Accessing the site.

3.4.2 Entering and exiting the power unit

When entering and exiting the power unit, the driver should follow biosecurity best practices to avoid contaminating the interior of the power unit. Refer to the biosecurity guidance outlined in the subsection 2.5.2 – Entering and exiting the power unit.

3.4.3 Loading deadstock into the transport unit

The biosecurity best practices that apply to a particular deadstock loading event depend on the level of handling required by the driver and whether they need to enter the animal holding sites to remove deadstock.

Biosecurity best practice

- Deadstock collection sites are situated away from animal holding sites.

- Minimize the driver's contact with the production site by collecting animals at a location that is away from the production unit.

The biosecurity best practice is to load deadstock from an area situated away from live animal holding facilities to prevent their contamination. It is recommended that staff from the animal holding facility remove deadstock from the production site and place at a designated location for pick up. This limits the driver's contact with the production site.

In situations where the driver must enter an animal production unit to remove a carcass then the biosecurity best practice is to wear a clean outer layer of clothing, hat, boots and gloves that are dedicated to tasks performed at the loading site.

Biosecurity best practice

- Contamination of the exterior of the transport unit and loading site is minimized and managed during loading.

If there is contamination to the exterior of the transport unit, then it is recommended that the deadstock transporter:

- moves the transport unit to an area away from the production facility and any pathways leading to or from the production facility;

- sprays the exterior of the transport unit and any exposed equipment with a disinfectant;

- uses a brush to remove any visible organic matter and respray those areas with the disinfectant; and,

- inspects the exterior of the transport unit and equipment to ensure it has been cleaned.

In a situation where the contamination is extensive, abort the route and go directly to your destination.

3.5 On the Road Phase

While on the road, be observant of any spillage or leaks. If you observe leaks, then stop and take appropriate corrective action to stop the leak. It is recommended that transporters carry a spill kit to contain and manage any accidental spills. From a biosecurity prospective, include the following in your spill kit:

- personal protective equipment (e.g. disposable coverall, eye protection, footwear, gloves, etc.);

- absorbent material (absorbent clay, fine sand, sawdust), liquid containment tubes, disinfectant and disinfectant sprayer;

- shovel and broom;

- disposal bags;

- duct tape; and

- a list of emergency contact information in the event of a large spill.

It is recommended that the spill kit be stored in a container with a lid and that its contents be checked regularly to ensure adequate supplies and expiration dates for the kit components.

3.5.1 Stops

Stops should be minimized and avoided when possible due to the high risk associated with transporting deadstock and rendering materials. Good planning can avoid the need to stop at restaurants and gas stations. If stops cannot be avoided:

- park as far away as possible from live animal transport units;

- avoid parking on gravel or loose surfaces;

- park on hard surface that can be decontaminated if leakage of fluids occurs; and,

- follow the entering and exiting the power unit biosecurity guidance outlined in section 2.5.2.

3.6 Unloading Phase

When accessing the unloading site follow any biosecurity requirements in place at the site. In addition:

- drive slowly upon arrival to limit the amount of debris that can contaminate the undercarriage and wheel wells;

- it is recommended that the driver work with someone on site to avoid having to handle the deadstock during unloading. If this is not possible, then personal protective clothing needs to be worn during unloading and disposed of prior to re-entering the power unit; and,

- unload the deadstock in such a way that prevents contamination of the exterior of the transport unit as much as possible.

If the driver needs to get out of the transport unit, then it is recommended that they wear:

- footwear that can easily be cleaned and disinfected (for example, rubber boots); and,

- an outer layer that can be taken off before re-entering the transport unit.

Biosecurity best practice

- Any disposable personal protective equipment such as boot covers, coveralls and gloves are disposed of on site.

Prior to leaving the site and/or commencing another deadstock pick-up route, it is recommended that the deadstock transport unit be cleaned and disinfected on site. If this is not possible, then it should be cleaned and disinfected at the earliest opportunity in a suitable facility.

Prior to leaving the site:

- place all potentially contaminated disposable boot covers and outer layers in a sealed bag and dispose of them on site; and,

- place cleaning brushes in a contained tote or bag that can be sealed prior to disposal.

4.0 Glossary

- Animal holding facility:

-

Any premises where live animals are kept for production (e.g. farms, feedlots).

- Best practices:

-

For this document, a best practice is a program, process, strategy, or activity that has been shown to be most effective in preventing and controlling disease. Best practices may have to be modified before implementation to accommodate a specific farm or facility and enhance practicality.

- Between Loads Phase:

-

Commences after the animals are unloaded and is completed when animals are loaded for the next transportation event. If the removal of organic matter (scrape-out) was not conducted at the destination, it may become a requirement during this phase.

- Biofilm:

-

A thin layer of microorganisms adhering to the surface of a structure, which may be organic or inorganic.

- Biosecurity:

-

Procedures and physical measures designed to reduce the risk of introduction, establishment and spread of animal or plant diseases, infections or infestations to, from and within a population.

- Cleaning:

-

A practice of removing visible organic matter. Cleaning is often considered a two-step process; dry cleaning by scraping out the transport unit followed by a wet cleaning with water.

- Disease:

-

A change from the normal state. A deviation or disruption in the structure or function of a tissue, organ or part of a living animal's body.

- Disinfection:

-

The process that is used to inactivate, decrease or eliminate pathogens from a surface or object.

- Downtime:

-

The period of time that a piece of equipment has not been used, usually after having been cleaned and disinfected.

- Health status:

-

Current state of health of the animal or herd, including both its condition and the presence of pathogens in the animal or herd. Information used to establish the health status includes the disease history and the results of any diagnostic testing, herd health management practices, vaccination and deworming protocols in sufficient detail to determine compatibility with the resident herd, and housing and movement detail sufficient to identify any potential recent disease exposure.

- Infection:

-

The invasion and multiplication or reproduction of pathogens such as bacteria, viruses, and parasites in the tissues of a living animal.

- Infectious disease:

-

Disease caused by pathogens (e.g. parasites, bacteria, viruses, fungi or prions).

- Livestock:

-

Includes animals of the bovine, caprine, equine, ovine and porcine species.