The risks to food safety and our animal and plant resources have changed considerably in recent years and continue to change rapidly. At the same time, the Canadian industry has to be more efficient and innovative to compete in a global economy. It is in this context that the Canadian Food Inspection Agency (CFIA) began to evolve the way it manages risk, supports industry's ability to compete globally, and embraces technology to provide more efficient and responsive service.

The CFIA committed to better use data, reports and surveillance to identify trends, allowing the Agency to focus on risk and support program design, planning, compliance and enforcement efforts. As part of the Strategic Integrated Risk Management priority, the CFIA developed an Establishment-based Risk Assessment model for Hatcheries (ERA-H) in order to allocate inspection resources based on food safety risks. This risk assessment takes into consideration the impact of Salmonella spp. on public health, and is being used to determine the level of oversight required to appropriately manage the risks. The ERA-H model has been developed by CFIA staff in collaboration with experts from academia, industry and other government departments. The development of the model also drew upon the experience acquired while developing the ERA model for food establishments.

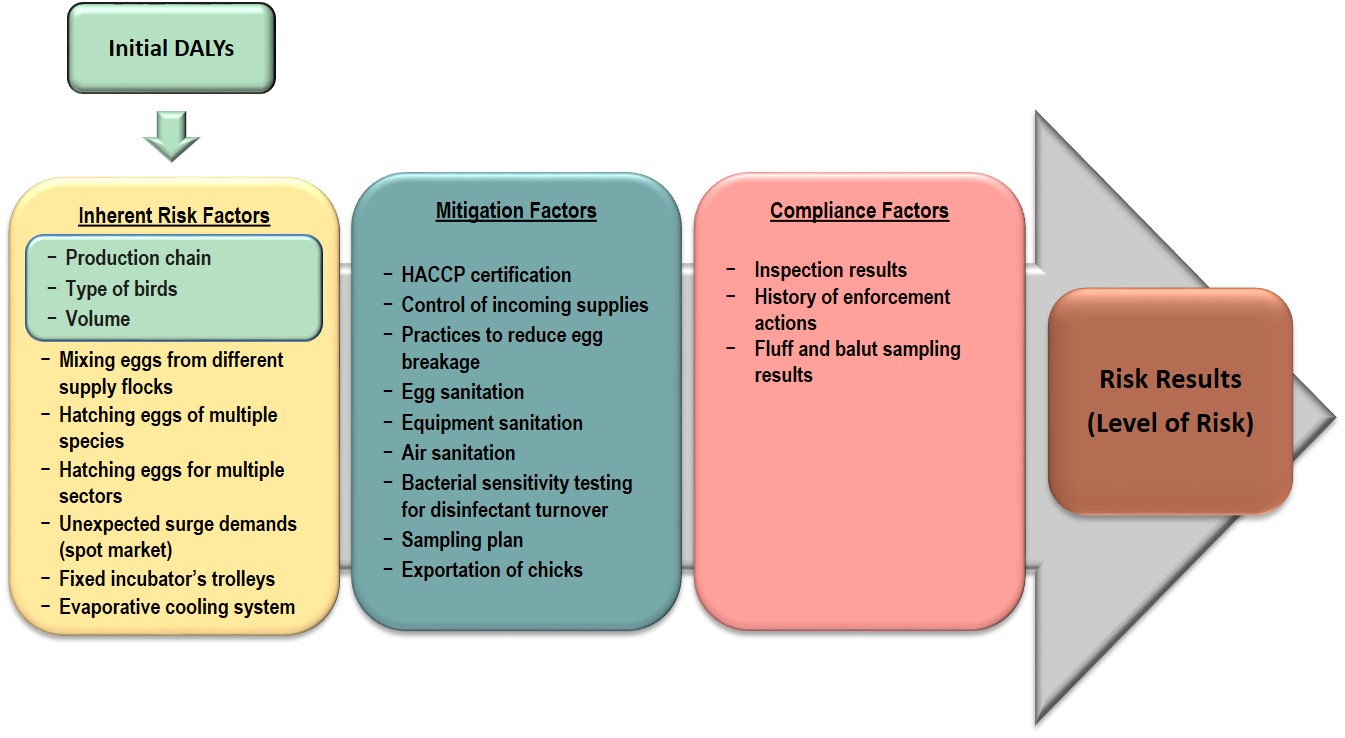

The ERA-H model has three different groups of risk factors: inherent risk factors, mitigation factors and compliance factors. Data for the first two components are collected through questionnaire provided to regulated parties by inspectors. Data on compliance factors are extracted from CFIA databases.

After a cycle of data collection and analysis by the ERA-H model, the risk results provide input into the Agency's risk-based approach to manage food safety risks, including the prioritization of inspection, oversight strategies and priorities as well as work planning. The ultimate objective of this initiative is to produce a near real time risk assessment for individual hatcheries that will assist the Agency within its overall integrated risk management strategy.

The scientific approach and practical applications to develop the ERA-H model since 2016 are presented below. Annex 1 presents the Scientific Advisory Committee members and the ERA-H technical working group.

Scientific approach and practical application

- Identification of factors associated with food safety risk

- Selection of risk factors for the ERA-Hatcheries model

- Risk factors' criteria weighting for the ERA-Hatcheries model

- Design of the ERA-Hatcheries model

- Testing of the model (pilot project)

- Performance assessment of the ERA-Hatcheries model outputs

- National data collection

Identification of factors associated with food safety risk

The objective was to identify the most meaningful food safety risk factors that could potentially be used in a risk assessment model for hatcheries. The main pathogen of interest was Salmonella spp. An initial literature review, along with advice from an expert panel, was used to develop a comprehensive list of risk factors that could potentially contribute to the food safety risk attributed to Canadian hatcheries in all types of production (breeders, layers, broilers, turkeys, waterfowls and gamebirds).

Selection of risk factors for the Establishment-based Risk Assessment model for hatcheries

For a quantitative risk assessment model, a limit number of risk factors is needed. Thus, other criteria were considered to select risk factors such as the clarity of their definition, the merging of risk factors sharing similar concepts, the inclusion of only measurable risk factors (for example the possibility that this factor can be objectively assessed during an inspection process), and the availability of data sources. The final list of risk factors is presented in Figure 1 and the process followed for their identification and selection is available in Zoonoses and Public Health. Briefly, risk factors are grouped into inherent risks factors, mitigation factors and compliance factors.

Inherent risk factors represent those associated with a specific type of operation or process. These factors take into account the production chain (that is, poultry meat and table-egg), the type of birds (for example, breeders, broilers), the production volume, and the practices known to increase the food safety risk associated with Salmonella spp. in hatcheries.

Mitigation factors are the measures or strategies that a hatchery is using to reduce the inherent risk, and therefore to reduce the risk of contaminating the poultry meat and egg production chains. Examples of these strategies include controlling the incoming supplies through farms with Quality Assurance (QA) programs, knowing the foodborne pathogen status of supply flocks, and the implementation of egg sanitation practices.

Compliance factors refer to a hatchery's track record with respect to how well it has complied with regulatory requirements. This is assessed using the hatchery's historical and current data such as information pertaining to Salmonella spp. fluff and balut sampling results, inspection reports and enforcement actions.

Description for image – List of risk factors included in the ERA-H model

This figure depicts the final list of risk factors included in the ERA-H model. The first box represents the inherent risk factors which are those associated with a specific type of operation or process. Three risk factors, namely the production chain, the type of birds, and the volume, are related to the attributed health impact (unit in DALYs – Disability Adjusted Life Years), attributed to these risk factors. The second box represents the mitigation factors which are the measures or strategies that a hatchery has implemented to control the inherent risks and to reduce the overall risk of a food safety issue. The third box represents the compliance factors which refer to a hatchery's track record on how well it has complied with regulatory requirements. The list under the inspector assessment is the list of preventive control plan (PCP) sub-elements that the ERA-H model considers under the CFIA's integrated Agency Inspection Model (iAIM).

Risk factors' criteria weighting for the Establishment-based Risk Assessment model for hatcheries

The objective was to quantify the relative importance of selected criteria used to measure the risk factors included in the ERA-H model and to estimate the contribution of the poultry meat/egg production chains and the bird type to the level of human Salmonella spp. illness in the Canadian population. Overall, 96 criteria were presented to 13 Canadian hatchery experts during a two-round face-to-face expert elicitation to estimate their relative risk to human health. There was broad consensus among participating experts on the relative risk given to the various criteria. Respondents' professional profile did not have an influence on the results. Median values for each criterion are used in the ERA-H model. The peer-reviewed scientific paper is available in Foodborne Pathogens and Disease.

Design of the Establishment-based Risk Assessment model algorithm for hatcheries

The ERA-H model concept is based on the allocation of risks to hatcheries based on their impact on consumers' health in Canada. The underlying principle is that the total impact (expressed as DALYs) remains constant, but the proportion allocated to individual hatcheries is fluid. This value takes into consideration the number of human cases attributed to Salmonella spp., the health impact per case of illness associated with it, and the attribution to the poultry meat and egg commodities, with the hatchery being the focal point of those commodities considered in the current model. Thus, the health impact is first allocated to individual hatcheries based the volume of each type of birds they distribute. The hatchery-level health impact is then adjusted considering the presence or absence of specific food safety criteria and their relative risks (Figure 2). A scientific paper is currently being prepared for submission to a peer-reviewed journal.

Description for image – ERA-H model arrow illustration

This figure illustrates the model design as an arrow. First, the initial DALYs are calculated by attributing the health impact to the three factors : production chain, type of birds and volume. Then, the health impact is adjusted by the inherent risk factors, the mitigation factors, and the compliance factors represented by the first, second and third boxes, respectively. This then generates the health impact at the hatchery level represented by the last box.

Testing of the model (pilot project)

The objectives of the pilot project were to obtain risk results and to validate the data collection tool. In 2017, 32 hatcheries were randomly selected and 29 participated. As a result of the pilot project data analysis as well as feedback from hatcheries and inspectors, an improved version of the data collection tool was developed.

Performance assessment of the Establishment-based Risk Assessment model outputs for hatcheries

The objectives of this step were to estimate the agreement between the risk assessments provided by the ERA-H model and CFIA senior inspectors, and to refine the model based on the identification of major discrepancies. Seventeen CFIA senior inspectors participated to the performance assessment at the beginning of 2018.

For each hatchery that participated in the pilot project, information related to the risk factors used as inputs in the ERA-H model was summarized in one page. Each expert categorized 10 hatcheries for their risk to the health of consumers, including 8 randomly selected hatcheries from the pilot project and 2 controls: one with the lowest risk and one with the highest risk. The controls were created by the ERA-H technical working group.

A moderate correlation was achieved between the ERA-H model and the risk assessment performed by CFIA's senior inspectors. Inspectors did not consider the production volume as significantly impacting the risk result of a hatchery. When fixing this variable, the correlation improved. No adjustment was made to the ERA-H algorithm.

National data collection

In order to collect information for the inherent and mitigation factors, a questionnaire was filled and current CFIA systems (compliance factors) are being used in order to assess the risk of all federally regulated hatcheries. The CFIA has completed the national data collection in all hatcheries under its jurisdiction as of August 2018. After a cycle of data collection and analysis by the ERA-H model, the risk results are being used in inspection planning and are providing input into the Agency's risk-based approach to managing food safety risks.

The Establishment-based Risk Assessment (ERA) model for food establishments was developed following the same scientific approach and this approach is actually being used to develop an Establishment-based Risk Assessment model for Feed establishments. The ERA technical working group is also currently adapting the ERA model for food importers (Importer Risk Assessment model).

Annex 1 – The Scientific Advisory Committee members and technical working group for the Establishment-based Risk Assessment model for hatcheries

| Name | Affiliation |

|---|---|

| Dr. Marie-Lou Gaucher, chief scientist | Université de Montréal |

| Dr. Sylvain Quessy | Université de Montréal |

| Dr. Jean-Pierre Vaillancourt | Université de Montréal |

| Dr. Michele T. Guerin | University of Guelph |

| Dr. Daniel Venne | Veterinary Practitioner |

| Dr. Ghislain Hébert | Veterinary Practitioner |

| Dr. Rachel Ouckama | Veterinary Practitioner |

| Dr. Darko Mitevski | Veterinary Practitioner |

| Dr. Agnes Agunos | Public Health Agency of Canada |

| Leanne De Winter | Public Health Agency of Canada |

| Angela Catford | Health Canada |

| Dr. Anna Mackay | Canadian Food Inspection Agency |

| Dr. Teresa Cereno | Canadian Food Inspection Agency |

| Name | Affiliation |

|---|---|

| Dr. Manon Racicot | Canadian Food Inspection Agency |

| Dr. Geneviève Comeau | Canadian Food Inspection Agency |

| Alexandre Leroux | Canadian Food Inspection Agency |

| Dr. Teresa Cereno | Canadian Food Inspection Agency |

| Dr. Maude Charron-Langlois | Canadian Food Inspection Agency |

| Sophie Benoit | Canadian Food Inspection Agency |

| Dr. Caroline Dubé | Canadian Food Inspection Agency |

| Dr. Marie-Lou Gaucher | Université de Montréal |