On this page

- 1. Purpose

- 2. Sampling methods

- 3. Preparing for shipping

- 4. Laboratory standards to provide testing and results

- 5. Analytical methods

1. Purpose

This annex provides information to help food businesses collect and prepare samples for the Pathogen Reduction Monitoring Program (PRMP) for Salmonella and Campylobacter in raw poultry.

It's your choice!

You may use other sampling and testing procedures developed by provincial counterparts, industry associations, international partners or academic bodies as long as they can achieve the same outcome. Always ensure that the guidance you use is tailored for your particular business, product or products, and market requirements. Ensure to have the proposal verified by the Canadian Food Inspection Agency (CFIA) for foreign country equivalency assessment.

What is not included!

While this document provides specific details regarding sampling for Salmonella and Campylobacter in poultry, it does not describe general best practices for sampling. Be sure to also consult the document Sampling procedures.

2. Sampling methods

2.1 Key considerations when sampling

- Consider time sensitivity of the samples

To obtain the most accurate results, the laboratory should analyse samples within 24 hours of collection.

When this cannot be achieved, such as for statutory holidays or weekends, collect the carcass and carcass parts, control it (them) under refrigeration and ship sample to the laboratory only when analyses can be guaranteed within 24 hours of shipment. For example, carcass and carcass parts that are collected on a Saturday will be controlled in the cooler, then sampled on Monday and sample can be shipped on the Monday.

For comminuted poultry, when this cannot be achieved, such as for statutory holidays or weekends, collect the sample, control it under refrigeration and ship sample to the laboratory only when analyses can be guaranteed within 24 hours of shipment. For example, comminuted poultry sampled on a Saturday will be controlled in the cooler and then shipped on the Monday.

- Remember the suitability of the samples: temperature

The laboratory will not analyze samples which are frozen (below 0°C) or too warm (with temperature greater than 10°C for rinsate).

Suitability criteria for samples is different for each pathogen, which means a sample which is not suitable for Campylobacter testing and may be suitable for Salmonella testing can be tested for Salmonella.

If samples need to be sent off-site, ensure that samples are maintained at refrigeration temperatures until transport and shipped refrigerated to the laboratory performing the analysis. Avoid storing shipping containers near heaters or in areas exposed to excessive heat. Do not freeze.

- Be prepared for sampling: check that all supplies are suitable

- Prepare and label, as necessary, your sampling supplies ahead of sampling

- Consider assembling in a tote which will also carry supplies to sanitize the sampling station

- Verify your sampling medium: discard any Buffered Peptone Water (BPW) solutions that are cloudy, turbid or contain particulate matter

Refrigerate solutions 24 hours prior to use.

- Ensure templates are sterile and dry

Templates can be reusable or not. They can be made of metal, aluminum foil, brown paper, flexible plastic, etc.

- Have means to control your sample, such as a tamper proof seal, as soon as collection is completed

2.2 Carcass rinse method for chicken carcass

Sampling supplies

- 15" × 20" (33 × 44 cm), large sterile plastic bag

- Pair of sterile gloves

- 400 mL bottle of pre-chilled Buffered Peptone Water (BPW)

- 120 mL sterile specimen jar with lid, labelled

- 1 liter re-sealable zipper-lock type bag (secondary container)

Sample collection – chicken carcass rinse

- Use aseptic techniques described in the document Sampling procedures

- Select the sample, at the randomly selected time

- Identify the point in the process where the carcasses will be selected for sampling: carcass are to be sampled from the post-chill area after all interventions have taken place and after sufficient drip time

- select a carcass and then count back or ahead 5 carcasses and select the next carcass for sampling (random, unbiased selection)

- if the sixth carcass is not a whole carcass with intact skin, count back or ahead an additional 5 carcasses for sample selection

- repeat until a whole carcass is available

- in establishments where the end location of the drip line makes removing a carcass from a moving line unsafe, pull the sample at the chiller exit, directly from the conveyor belt ensuring sufficient drip time

- if the final antimicrobial intervention is temporarily displaced because of an unforeseen event such as equipment malfunction, select a carcass after the alternate final intervention

- take the randomly selected carcass

- open the sampling bag without touching the sterile interior

Do not let anything but the sampled carcass touch the interior of the sampling bag

- put on sterile gloves

- grab the bottom exterior of the bag and push up through the bottom to form a "glove"

- grab the carcass by the leg; allow drainage of excess fluid to prevent dilution of the rinsate (such as allowing a drip time of at least 1 minute) taking care to avoid cross-contamination

- use other hand to pull the bag, from the exterior surface, back over the carcass

- open the sampling bag without touching the sterile interior

- Prepare the sample

- place the bag with the carcass on the flat sanitized surface

- open the BPW container and pour the BPW over the carcass in the bag

- manipulate the loose neck skin over the neck bones through the bag

- expel the excess air from the bag, twist it closed, and fold the twist over

- while securely holding the closed bag, rinse the carcass inside and out using a rocking motion for approximately 1 minute

This assures both interior and exterior of the carcass get rinsed

- place the bag with the chicken on the sanitized flat surface with the top of the bag facing up

- remove the screw-cap from the sterile sample container, and put the cap in the small re-sealable sterile bag

- open the large bag with the chicken, and pour 100 ml of the BPW liquid into the sterile sample container

- take the screw-cap out of small re-sealable bag, and close the sample container.

- ensure that the lid is correctly threaded, and do not over-tighten

- place sample container in the secondary zipper-lock bag, removing excess air

- discard the remaining liquid

- return the chicken to the chill tank or to location where the carcass was collected

Quick tip

Sampling can also be performed by 2 people wearing sterile gloves:

- 1 to hold the bag open

- 1 to grab the carcass, to pour the BPW

2.3 Carcass sponge method for turkey carcass

Sampling supplies

- 3 pairs of sterile gloves

- 1 - 10 mL tube of pre-chilled BPW marked "S" (Salmonella)

- 1 - 25 mL tube of pre-chilled BPW marked "C" (Campylobacter)

- 2 - sterile specimen sponges (swabs) in marked zipper-lock bags; 1 swab labelled "C", one swab labelled "S"

- 2 - sterile templates 5cm × 10cm in bag (1 for Salmonella, 1 for Campylobacter)

- 2 - 1 liter re-sealable zipper-lock bags (secondary container)

Sample collection

- Use aseptic techniques described in the document Sampling procedures

- Select sample, at the randomly selected time

- identify the point in the process where the carcasses will be selected for sampling: carcasses are to be sampled from the post-chill area after all interventions have taken place and after sufficient drip time

- select a carcass and then count back or ahead 5 carcasses and select the next carcass for sampling to avoid any possible bias during selection

- if the sixth carcass is not a whole carcass with intact skin, count back or ahead an additional 5 carcasses for sample selection

- repeat until a whole carcass is available

- in establishments where the end location of the drip line makes removing a carcass from a moving lie unsafe, pull the sample at the chiller exit, directly from the conveyor belt

- if the final antimicrobial intervention is temporarily displaced because of an unforeseen event such as equipment malfunction, select a carcass after the alternate final intervention step

- take the randomly selected carcass; allow drainage of excess fluid to prevent dilution of the rinsate (such as allowing a drip time of at least 1 minute) taking care to avoid cross-contamination.

Do not touch the back or thigh areas.

- Prepare the samples using aseptic techniques and changing sterile gloves as necessary:

- sample for Salmonella first (sampling supplies marked "S"), on left side of carcass

- place the carcass on a rack or breast-down on paper towels

- do not let sample sites touch any surfaces

- open sponge bag

- pour smaller BPW container marked "S" into sponge bag marked "S"

- close bag and massage sponge; squeeze sponge and push to top of bag

- open sponge and template bags and set bags on sanitized surface

- retrieve sponge and template aseptically

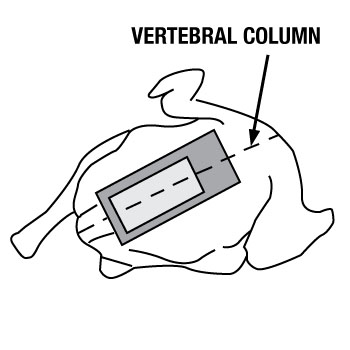

- position and hold the template just above the tail, to the left of the vertebral column (picture A), avoiding all contact to the sampling area

- wipe the sponge over entire sample area (10 vertical swipes and 10 horizontal swipes)

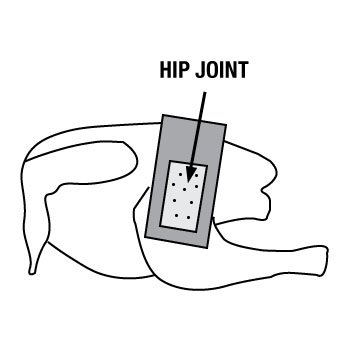

- reposition and hold the template over the left thigh (lateral to hip - Picture B), avoiding all contact to the sampling area

- turn sponge over and wipe unused side over entire sampling area(10 vertical swipes and 10 horizontal swipes)

- place the sponge in the sampling bag (marked with an "S") and seal the bag

- discard the template

- put on new pair of sterile gloves to proceed with same procedure on the right side of carcass for Campylobacter (sampling supplies marked "C")

- place sample bags in the secondary zipper-lock bag, removing excess air

- place bagged carcass sponges under refrigeration within 5 minutes of collection

2.4 Carcass parts rinse method for chicken

Sampling supplies

- 15" X 20" sterile plastic bag

- Sterile gloves

- Sterile wide-mouth container with 400 ml of sterile pre-chilled Buffered Peptone Water (BPW)

- 120 ml sterile specimen jar with lid

- 1 liter re-sealable zipper-lock type bag (secondary container)

Sample collection – chicken parts

- Use aseptic techniques described in the document Sampling procedures

- Select the sample

- identify the point in the process where the raw chicken parts will be selected for sampling

- finished chicken parts are to be sampled prior to freezing, unless an intervention achieving Salmonella or Campylobacter reduction is applied at or after freezing.

For example, a product will be collected in its final consumer ready packaging when a final intervention is applied at packaging.

- select only 1 specific chicken part subtype per sampling event, alternating subtypes for each sampling event

For example, when selecting chicken breast tenderloins for one sampling event, do not sample other breast pieces or other parts such as legs.

- randomly collect the selected chicken parts, ensuring the sample is representative of a full day of production, and:

- represents each shift

- represents each production line that produces the product

- totals 1.8 kg (or 4 lbs.) ± 10% in weight

- Prepare the sample

- place chicken parts into the sampling bag, avoiding any transfer of excess processing liquid

- when sample is complete, pour BPW in sampling bag, massage and collect the rinsate immediately in sterile specimen jar

- place the jar with the rinsate sample in an ice bath immediately after sample collection or refrigerate the sample within 5 minutes of collection

- hold the rinsate in a refrigerator set at 4° C or lower

Do not freeze the sample.

- place container in the secondary zipper-lock bag, removing excess air

2.5 Raw comminuted chicken and turkey

Sampling supplies

- Sterile gloves

- Sterile scoop and spatula (if needed)

- Sanitized scissors when used for cutting through bags

- 24 oz. lined zipper-lock bags

- Re-sealable zipper-lock type bag

Sample collection

- Use aseptic techniques described in the document Sampling procedures

- Select the sample

- Identify the point in the process where the products will be selected for sampling; the raw ground or comminuted poultry are to be sampled prior to freezing, unless an intervention achieving Salmonella or Campylobacter reduction is applied at or after freezing

For example, a product will be collected in its final consumer ready packaging when a final intervention is applied at packaging. Whenever possible, collect finished product in its final package, otherwise collect as close to packaging as possible.

- Identify the product subtype to be sampled for the sampling event and label sampling supplies accordingly

- Randomly collect the identified product subtype from available eligible product.

For example, for "other comminuted", collect fresh raw sausage and fresh raw patties

- Collect the identified product so that the sample equals approximately 900 grams ± 10%

- For product collected in its final packaging, place the packaged sample in a non sterile bag

- For product that is not collected in its final packaging (for example, from a combo/a box), collect the sample aseptically and place in a sterile sample bag

Carefully close the bag hermetically to avoid leakage: squeeze out air, tightly fold over top 4 times and secure side tabs tightly without tying together

- place sample in the secondary zipper-lock bag, removing excess air.

- Identify the point in the process where the products will be selected for sampling; the raw ground or comminuted poultry are to be sampled prior to freezing, unless an intervention achieving Salmonella or Campylobacter reduction is applied at or after freezing

3. Preparing for shipping

Shipping supplies

- Sample seal for tamper proofing

- Absorbent pad

- Cardboard separator(s)

- Frozen gel coolant pack(s) (place in freezer 24 hours prior to shipping)

- Shipping container, with foam plug as applicable

Packaging procedure

- maintain sample security and identification

- place in the shipping container in the following order:

- the absorbent pad

- the frozen gel coolant pack

- the cardboard separator (this will prevent the sample from freezing)

- the sample collection jar or sample bag, within the secondary zipper-lock bag, placed upright

Do not tape or wrap the sampling container, as laboratories may refuse the sample.

- a second cardboard separator followed by a second frozen gel pack if there is added risk that the temperature of the sample could get compromised (for example summer heat, long transport time)

- the foam plug, if available, directly on top of the sample jar, pressing down slightly to secure contents.

Do not overfill the shipping container

- place the insulated lid on the container

- seal the shipping container

- maintain shipping container under appropriate temperature control until pick-up

- ship the sample in order for laboratory analysis to be completed within 24 hours of shipment

4. Laboratory standards to provide testing and results

To be eligible to provide testing and results, laboratories should be accredited by the Standards Council of Canada (SCC) or Canadian Association for Laboratory Accreditation Inc. (CALA) and have on their scope of approved methods, the method(s) of analysis prescribed by the Health Canada and/or United States Department of Agriculture – Food Safety and Inspection Service (USDA-FSIS) or with approved alternative methodology.

Laboratories may refer to the Health Canada's Compendium of Analytical Methods and to FSIS - Microbiology Laboratory Guidebook websites to ensure that the most current versions are used.

Laboratories are responsible for:

- maintaining laboratory accreditation with the SCC or the CALA under the Standards "General requirements for the competence of testing and calibration laboratories" ISO/IEC 17025:2005 and "Requirements for the Accreditation of Agriculture Inputs, Food, Animal Health and Plant Protection Testing Laboratories (ref.CAN-P-1587 April 2008)

- demonstrating ongoing proficiency for requested testing through a microbiology proficiency testing scheme

- admitting and/or disposing of samples for testing according to the applicable criteria described

- conducting testing for according to the technical requirements in this guidance document

- sending results for each individual test simultaneously and directly to the establishment Canadian Food Inspection Agency (CFIA) veterinary inspector and licence holder

- indicating on the laboratory report specific Health Canada, USDA-FSIS or the approved equivalent method used

- making available to the CFIA information on the condition of samples received

- maintain records of tests performed

5. Analytical methods

The methods will be referred to in accredited laboratories scope such as:

MLG 4C.07 - FSIS Procedure for the Use of a Polymerase Chain Reaction (PCR) Assay for Screening Salmonella in Meat, Poultry, Egg, and Siluriformes (Fish) Products and Carcass and Environmental Sponges

MLG 4.10 - Isolation and Identification of Salmonella from Meat, Poultry, Pasteurized Egg, and Siluriformes (Fish) Products and Carcass and Environmental Sponges

MFLP-29 - The Qualicon Bax® System Method for the Detection of Salmonella in a Variety of Food and Environmental Samples

MFHPB-20 - Isolation and Identification of Salmonella from Foods

MLG 41.04 - Isolation and Identification of Campylobacter jejuni/coli/lari from Poultry Rinse, Sponge and Raw Product Samples